Project machinery and turntable bearing oil overflow collection device thereof

A technology for slewing bearings and grease collection, applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve problems such as environmental pollution, mechanical equipment failure, grease overflow, etc., to avoid environmental pollution, prevent personal safety, and reduce failures rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

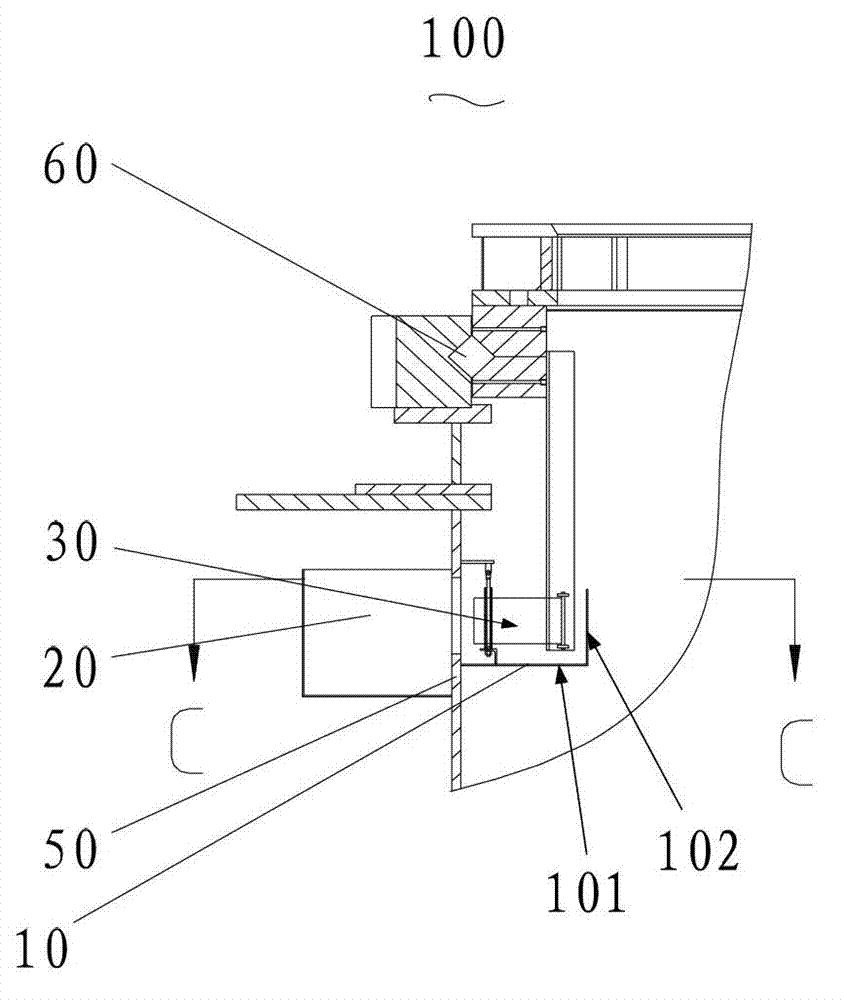

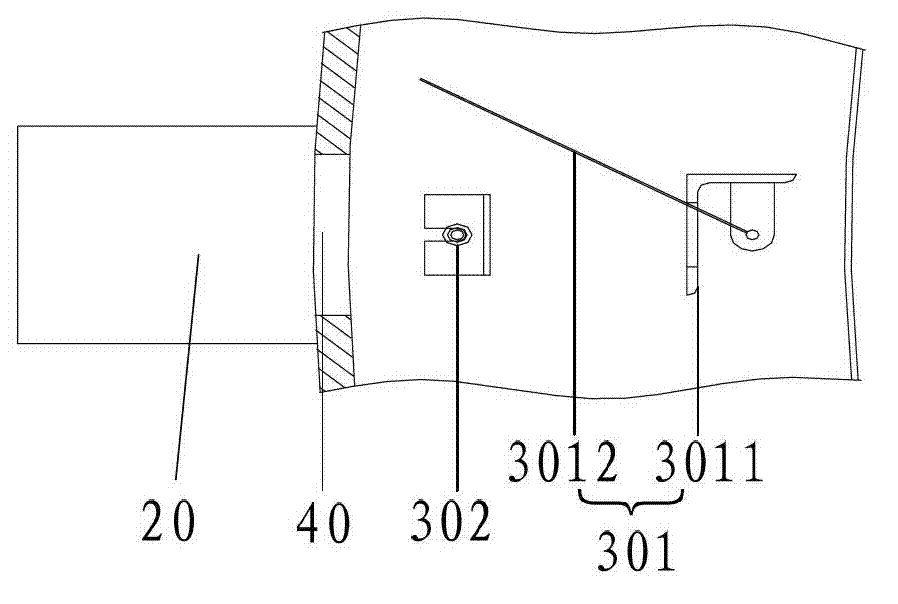

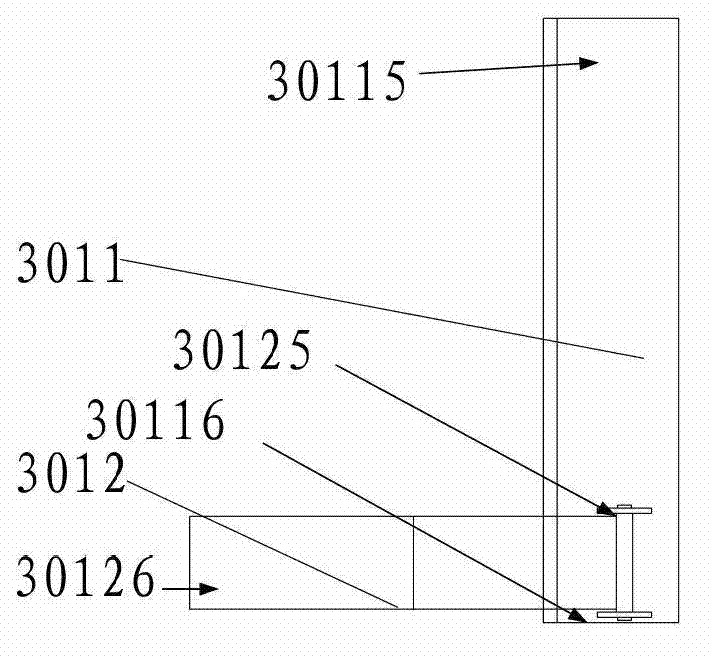

[0033] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the front view of the embodiment of the device for collecting overflowing grease from the slewing bearing of the present invention, figure 2 Yes figure 1 The enlarged cross-sectional schematic diagram of the C-C direction of the overflow grease collection device of the slewing bearing is shown. The device 100 for collecting oil spilled from the slewing bearing of the embodiment of the present invention includes: an oil receiving mechanism 10 , an oil storage container 20 , an oil driving mechanism 30 and an oil delivery channel 40 . In order to clearly express the positional relationship of the various components in the device 100 for collecting overflowing grease from the turntable bearing, the web 50 and the turntable bearing 60 are also shown in the figure.

[0034] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com