Demagnetization method of magnetic powder

A magnetic powder, demagnetization technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve problems such as elevation, easy movement of conductive particles, and aggregation of conductive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

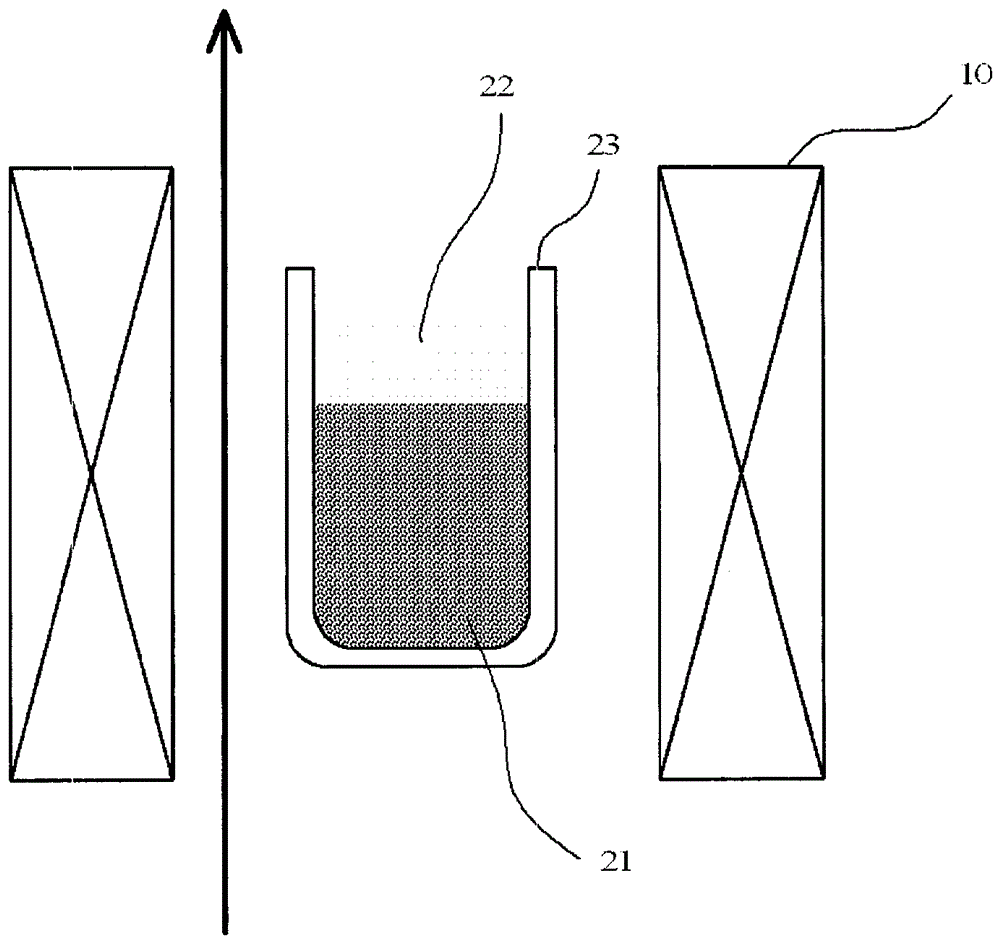

[0050] Example 1 (demagnetization treatment by the second mode of the demagnetization method)

[0051] (Demagnetization treatment of conductive particles)

[0052] 100 g of nickel-coated resin particles with an average particle diameter of 3 to 4 μm, prepared as described later, were put into a solvent-resistant cylindrical container made of glass with a capacity of 900 ml and an opening inner diameter of 10 cm and a depth of 20 cm. Alkanes 500g, disperse and mix.

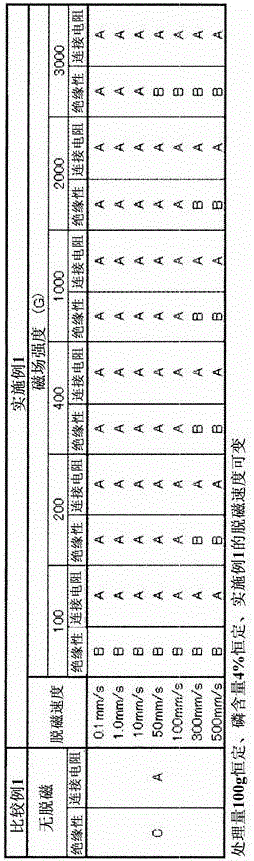

[0053] The cyclohexane mixture was cooled to -40°C to solidify. The glass container containing the solidified cyclohexane mixture was placed in a through-type demagnetization device (manufactured by Soni Chemicul & Informatics Co., Ltd.), and the demagnetization treatment was performed under the conditions shown in Table 1 and Table 2. After the demagnetization treatment, the temperature was returned to room temperature, and nickel-coated resin particles were obtained by filtration from cyclohexane, washed with h...

Embodiment 2

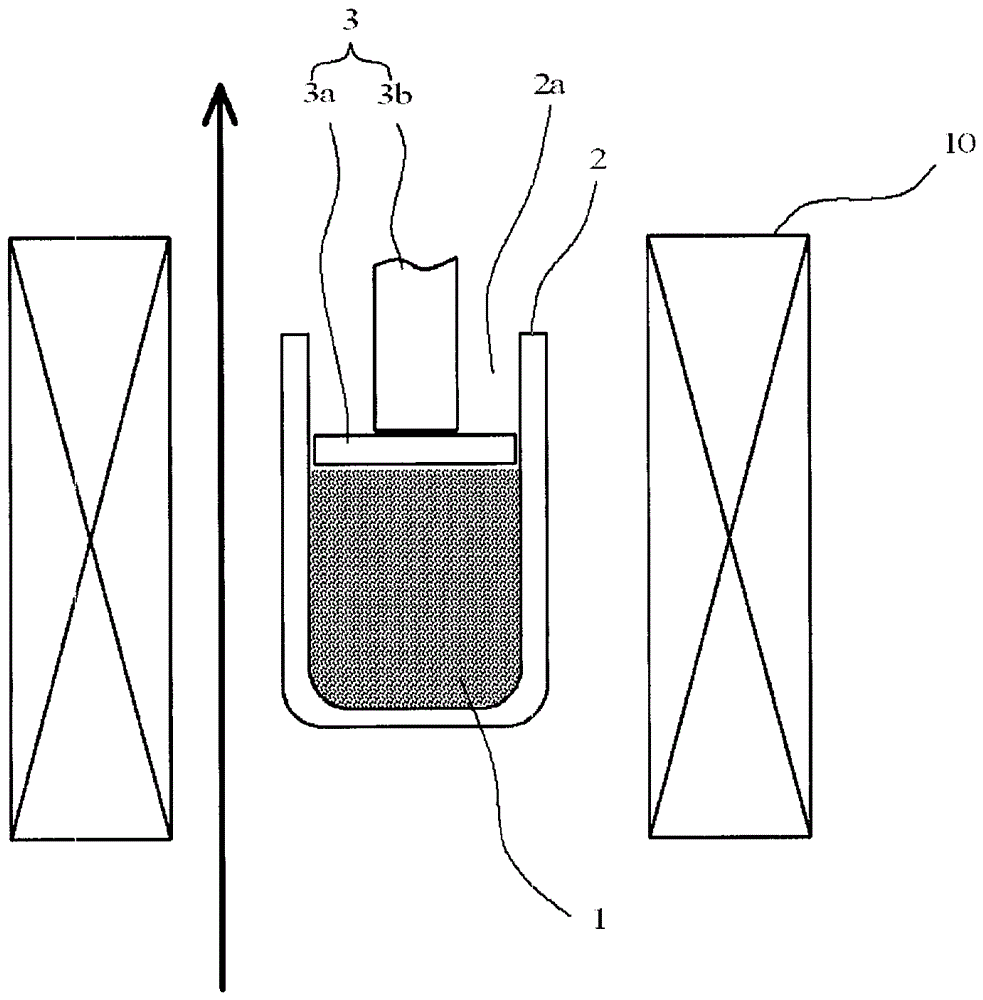

[0090] Example 2 (Demagnetization treatment by the first mode of the demagnetization method)

[0091] In a solvent-resistant cylindrical vessel made of glass with an opening inner diameter of 60 mm and a depth of 70 mm and a capacity of 100 ml, the same nickel-coated resin particles (demagnetized) with an average particle diameter of 3 to 4 μm as the particles prepared in Example 1 were placed. Untreated) 100g. The surface of the resin particle was located 20 mm away from the mouth. In addition, nickel contains 4 mass % of phosphorus atoms.

[0092] Next, a disk-shaped glass plate with a diameter of 60 mm and a thickness of 10 mm was placed on the surface of the resin particles from the opening, and it was pressed with a force of 500 N to detachably fix it. The glass container was placed in a through-type demagnetization device (manufactured by Soni Chemicul & Informatics Co., Ltd.), and demagnetized at room temperature with a magnetic field intensity of 400G and a demagneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com