Method for determining towing load of triangular truss-type pile leg of self-elevating drilling platform

A drilling platform and triangular technology, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve problems such as troublesome calculation and analysis process, low work efficiency, and complexity, so as to improve the work efficiency of pile leg strength analysis and improve work efficiency. Efficiency, the effect of simplifying calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

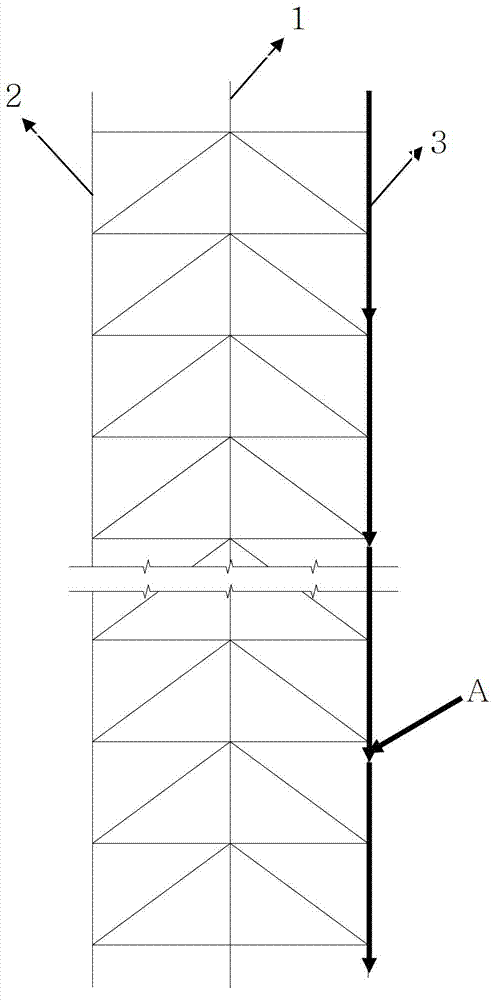

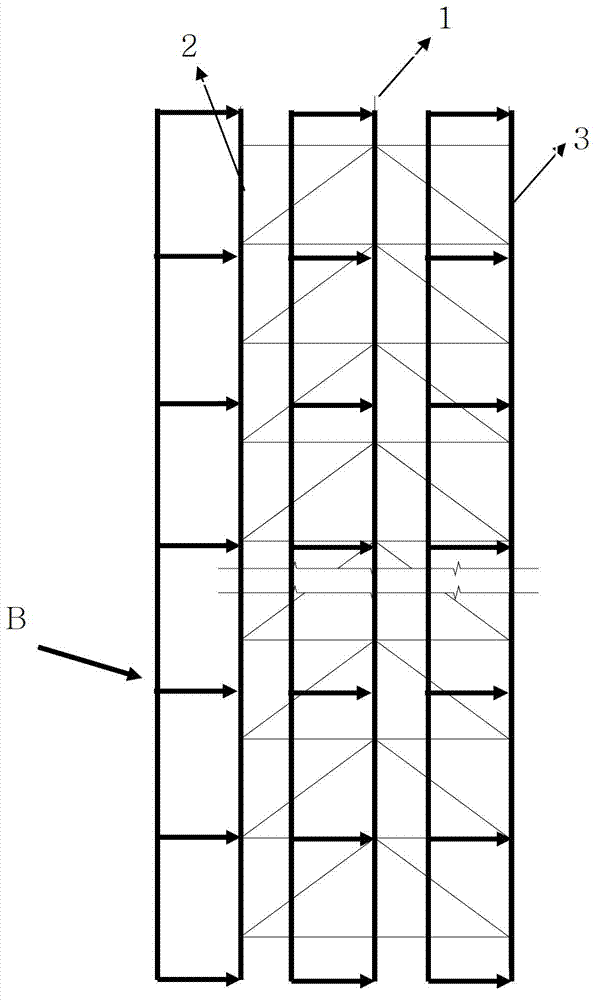

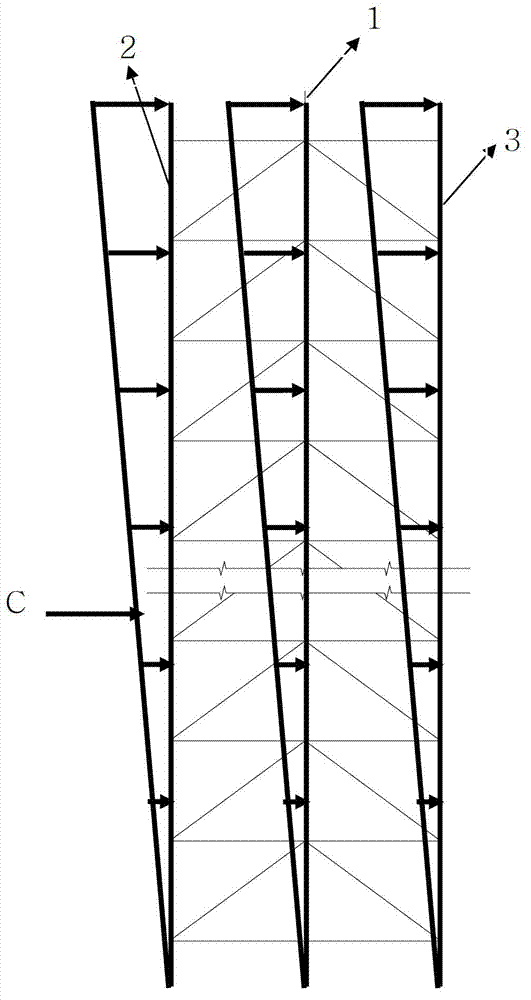

[0055]The self-elevating platform includes three legs, which are respectively located on the bow, port and starboard sides of the platform. The legs located at the bow of the platform are called the front legs, and the two legs located on the port and starboard sides of the platform are called the rear legs. Each leg is a triangular truss structure, the front leg is located at the center longitudinal line, the inertia load suffered by the roll is small, the inertia load suffered by the left and right sides is larger and the same, if the port side pile If the leg meets the strength requirements, the strength of the other legs must also meet the requirements. Therefore, to simplify the calculation, only the strength of the port leg is analyzed during rolling. During pitching, the inertial loads suffered by the left and right sides of the legs are the same, but the distance between the front legs is farther from the center of rotation, and the inertial loads suffered by them are g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com