Adapter for output shafts of tubular drive devices for winding and unwinding, especially roller blinds, etc., of shading devices

A technology for driving equipment, adapters, applied in the direction of door/window protection devices, windows/doors, building components, etc., can solve problems such as obstructing driving equipment or installation of tubular motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

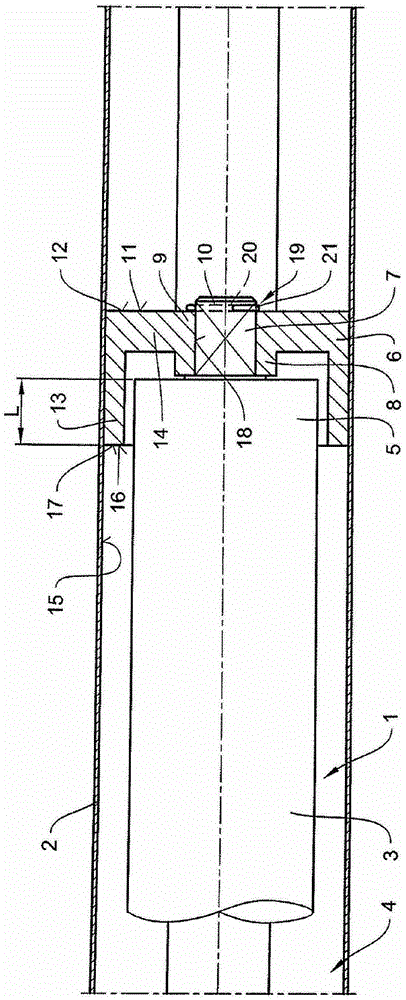

[0012] The tubular drive device 1 partially shown in the drawing for winding and unwinding, in particular roller blinds etc. A motor (not shown) and a transmission mechanism connected thereto (also not shown) are integrated in the housing 3 .

[0013] The housing 3 of the drive device 1 is passed through an adapter or an adapter ring (not shown) with its end 4 directed toward the lateral abutment of the mandrel 2 and with its end facing away from the lateral abutment of the mandrel 2 The end 5 of 4 is non-positively and / or positively connected to the reel 2 via a further adapter 6 . In this case, the roll 2 preferably has an octagonal cross-section. Furthermore, the housing 3 of the drive device 1 is secured against rotation at its end 4 directed toward the lateral bearing of the mandrel 2 by means of a torque bearing (not shown).

[0014] Preferably, the adapter 6 is made of plastic, whereby the manufacture of the adapter 6 is relatively simple and inexpensive.

[0015] At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com