Automatic efficient moisture removal device for non-woven fabric drying oven

A non-woven fabric and oven technology, applied in heating device, drying gas arrangement, drying and other directions, can solve the problems of inconvenient to pass through cloth, unable to achieve drying effect, slow forward transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

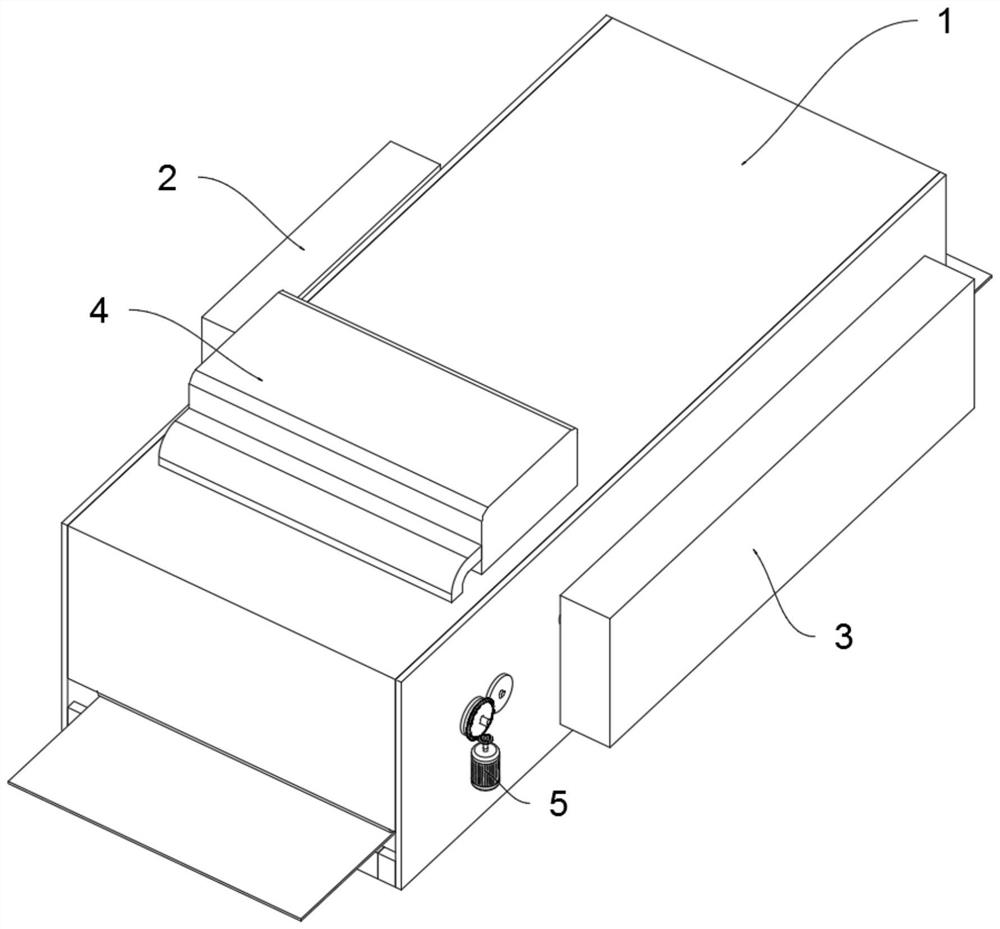

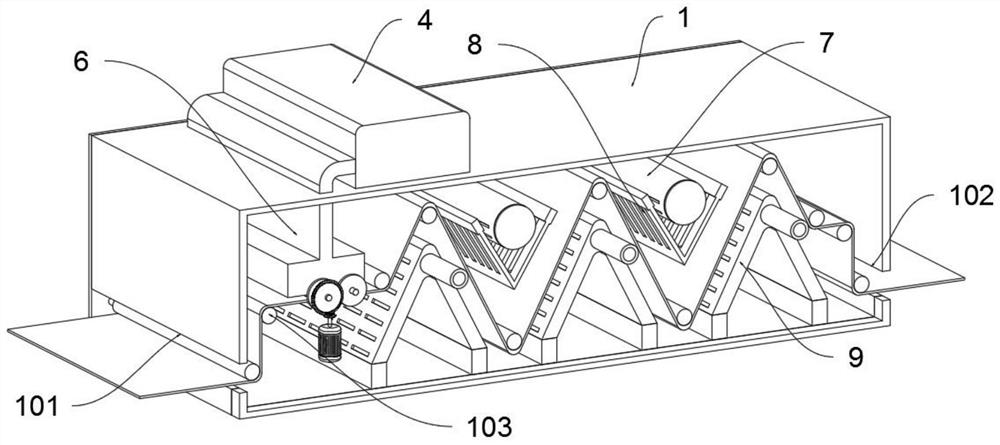

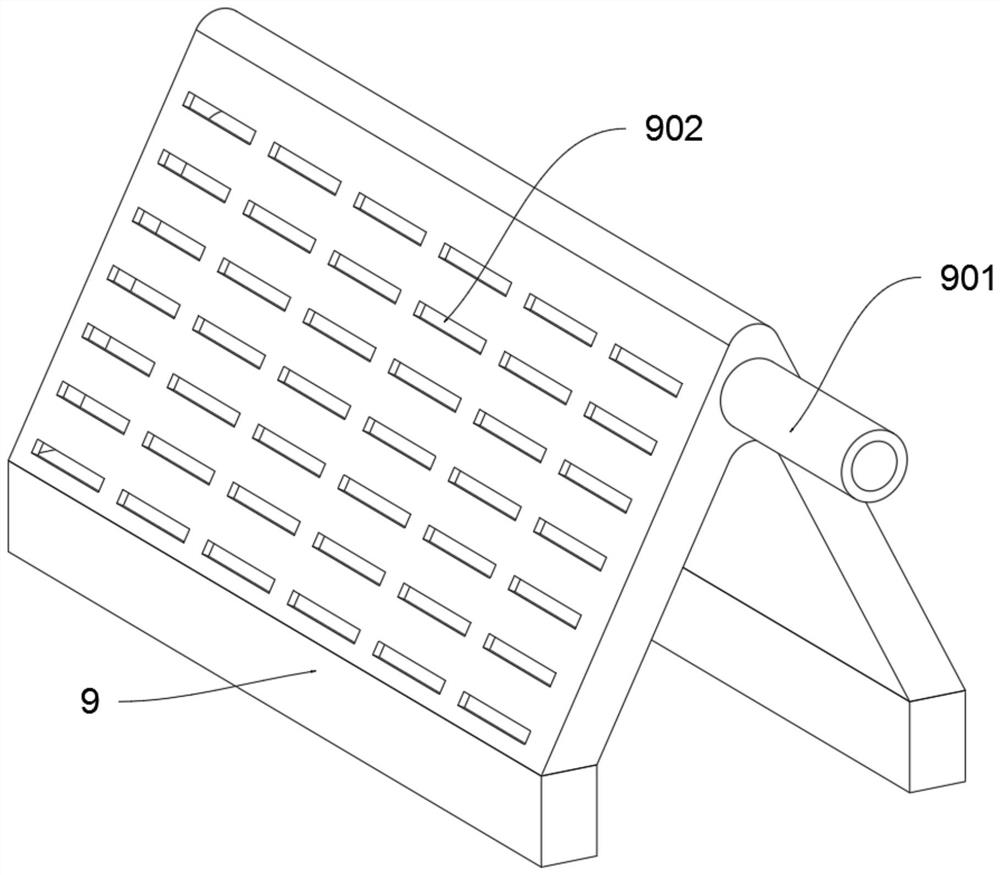

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides an automatic high-efficiency dehumidification device for a non-woven fabric oven, which includes an air inlet fan 2, an air outlet fan 3, a dust exhaust fan 4, a drive motor 5, a dust removal and flattening mechanism 6, a blower cylinder 7, an electric heating plate 8, and an exhaust fan. The air base frame 9; the air intake fan 2 is fixedly connected to the outside of the outer box body 1 by bolts; the air outlet fan 3 is fixedly connected to the right side of the outer box body 1 by bolts; the driving motor 5 is connected to the right side surface of the outer box body 1 by welding The dust removal and flattening mechanism 6 is fixedly connected to the inner upper surface of the outer box body 1, and the upper pipeline of the dust removal and flattening mechanism 6 is fixedly connected to the upper surface of the outer box body 1; the dust exhaust fan 4 is fixedly connected to the outer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com