A Rod Insulator for Low-Voltage Lines

A technology of low-voltage lines and insulators, applied in insulators, suspension/strain insulators, circuits, etc., can solve problems such as high cost, increased creepage distance, waste, etc., and achieve the effect of saving a lot of cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

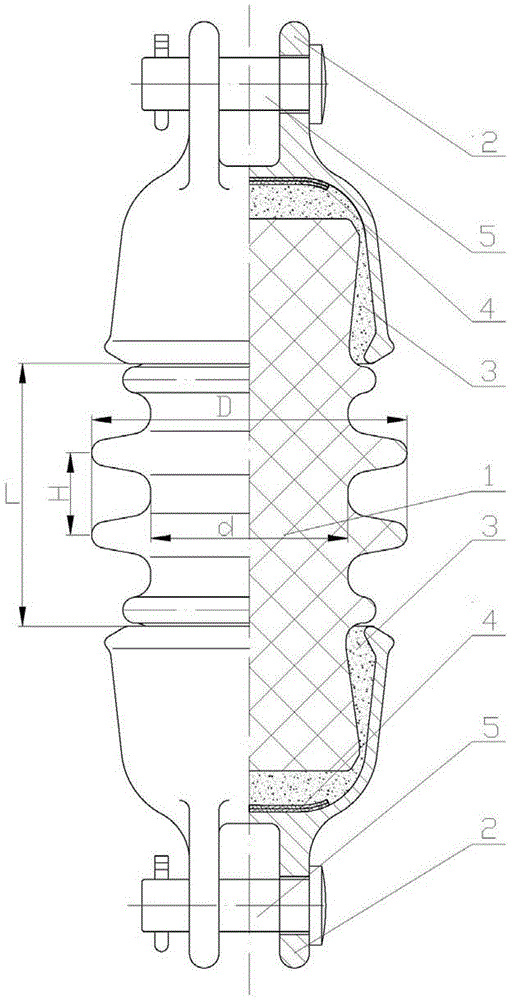

[0015] see figure 1 , the rod-shaped insulator for low-voltage lines of the present invention includes a rod-shaped insulator 1 and two metal caps 2 respectively sleeved on both ends of the insulator 1, and the outer end of each metal cap 2 extends axially outwards with a pair of Ear climbers, each pair of ear climbers is provided with a pair of perforations, and each pair of perforations is used to install cylindrical pins 5, so that the present invention can be easily installed on various occasions;

[0016] The diameter d of the insulator 1 is 50~60mm, and the middle part of the insulator 1 is provided with a two-layer umbrella edge with a distance I of 25~29mm, so that the insulation linear distance L is elongated to 80~90mm, and the respective diameters of the two-layer umbrella edges D Both are 90 ~ 94mm, so that the creepage distance can reach 120mm, which meets the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com