A printed circuit board mount

A technology for printed circuit boards and mounting bases, applied in the direction of support structure installation, etc., can solve the problems of increasing creepage distance, creepage, affecting electrical performance, etc., to avoid creepage phenomenon, improve safety performance, and facilitate heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

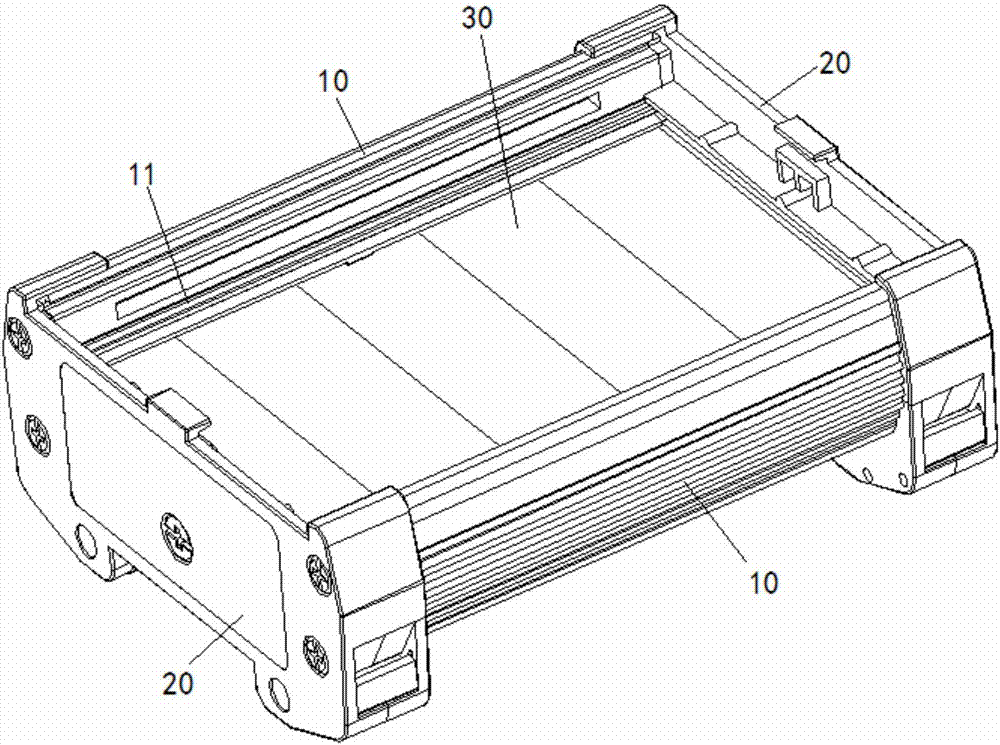

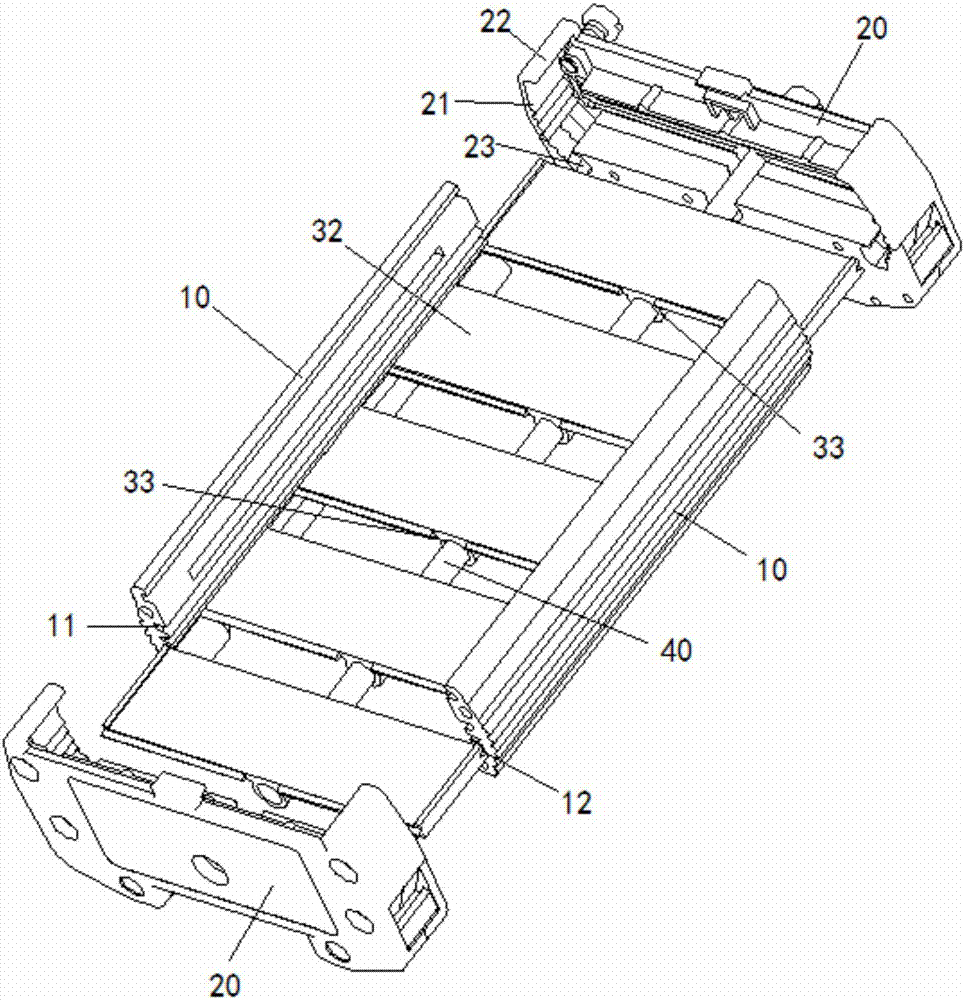

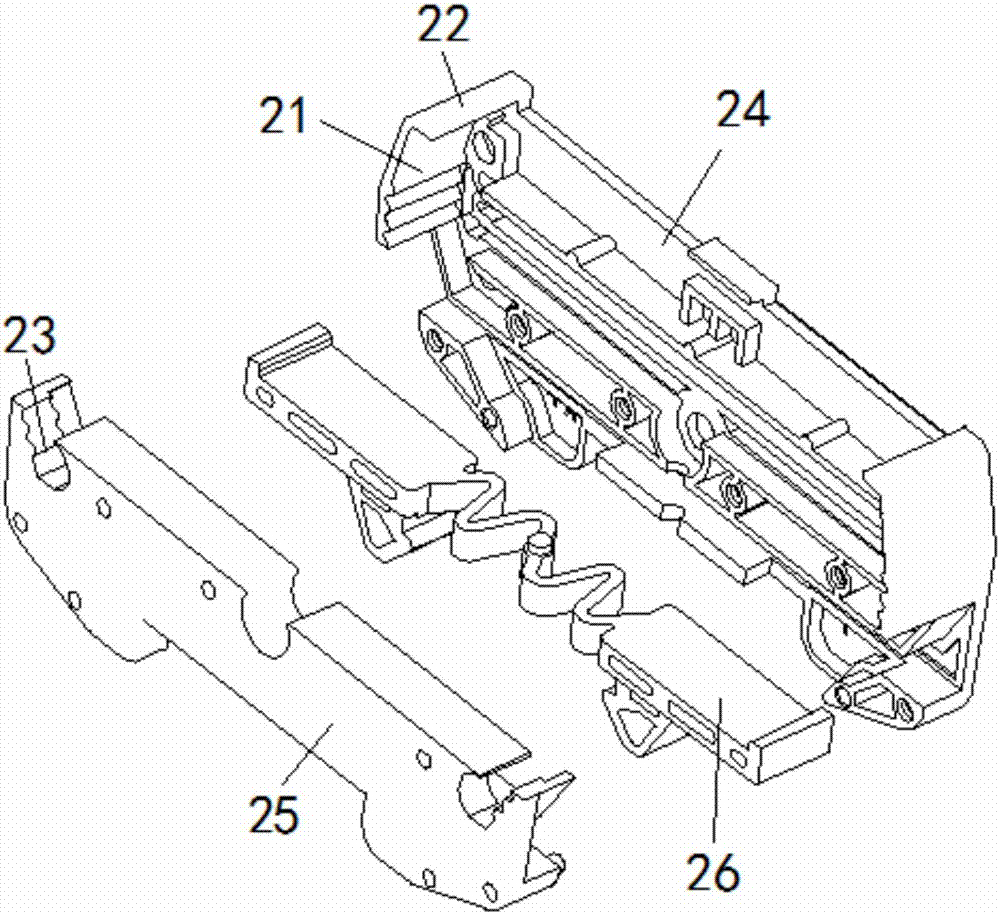

[0021] like Figure 1 to Figure 3 As shown, a printed circuit board mounting seat according to the present invention includes two side plates 10 respectively located on two opposite sides, and two ends respectively connected to the two ends of the side plates 10 and positioning the side plates 10 Cover 20, the upper inner side of the side plate 10 is provided with a chute 11 that can be installed with an electronic module circuit board, and also includes a pull rod 40 with two ends connected to the two end covers 20 respectively, and the pull rod 40 pulls Tighten the two end caps 20 to keep them close together. A guide groove 12 is provided on the inner side of the side plate 10 , and a bottom plate 30 is installed in the guide groove 12 . The bottom plate 30 includes a plurality of plates 32 , ear portions 33 are provided on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com