A sewage pre-filter device and its application

A pre-filtration and sewage technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems affecting the effect of sewage pretreatment, etc., and achieve the effect of pre-filtration treatment and accelerated effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

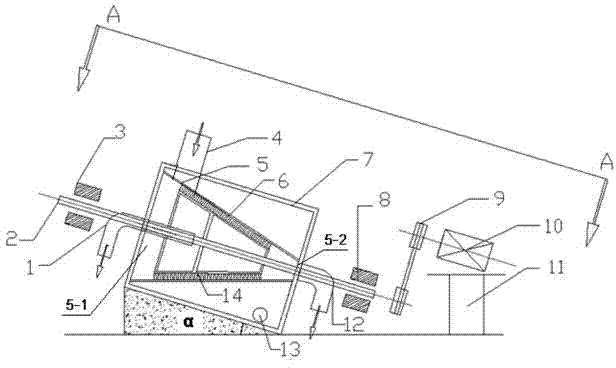

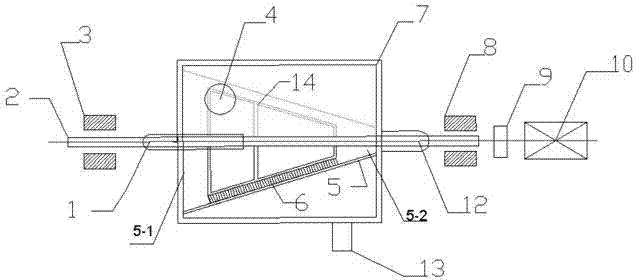

[0029] Such as Figure 1-2 shown.

[0030] A sewage pre-filtering device comprises a water storage tank 7, a light impurity outlet 1 and a sludge outlet 12 respectively provided at both ends of the water storage tank 7, a sewage inlet 4 is arranged at the top of the water storage tank 7, and a sewage inlet 4 is arranged at the top of the water storage tank 7 The bottom of 7 is provided with a clear water outlet 13, a conical filter cloth sieve drum 5 is provided in the water storage tank 7 and along the axial direction of the water storage tank 7, and a conical filter cloth sieve drum 5 is provided in the conical filter cloth sieve drum 5 Trapezoidal rotor 14, bristles 6 are arranged on the two hypotenuses of the trapezoidal rotor 14; the inclination angle of the trapezoidal rotor 14 is the same as the internal inclination angle of the conical filter cloth screen drum 5;

[0031] The water storage tank 7 is inclined to the horizontal plane, and the inclination angle α is 25°;...

Embodiment 2

[0040] A sewage pre-filtering device as described in Embodiment 1, the difference is that the water storage tank 7 is inclined to the horizontal plane, and the inclination angle α is 20°.

Embodiment 3

[0042] A sewage pre-filtering device as described in Embodiment 1, the difference is that the water storage tank 7 is inclined to the horizontal plane, and the inclination angle α is 50°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com