Movable cantilever structure of magnetic suspension train

A technology for maglev trains and activities, applied in electric vehicles, vehicle parts, electric traction, etc., can solve the problems of many mechanical failure factors, high line requirements, and high investment costs, and achieve simplified complexity and technical difficulty, simple technology, Facilitate the effect of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

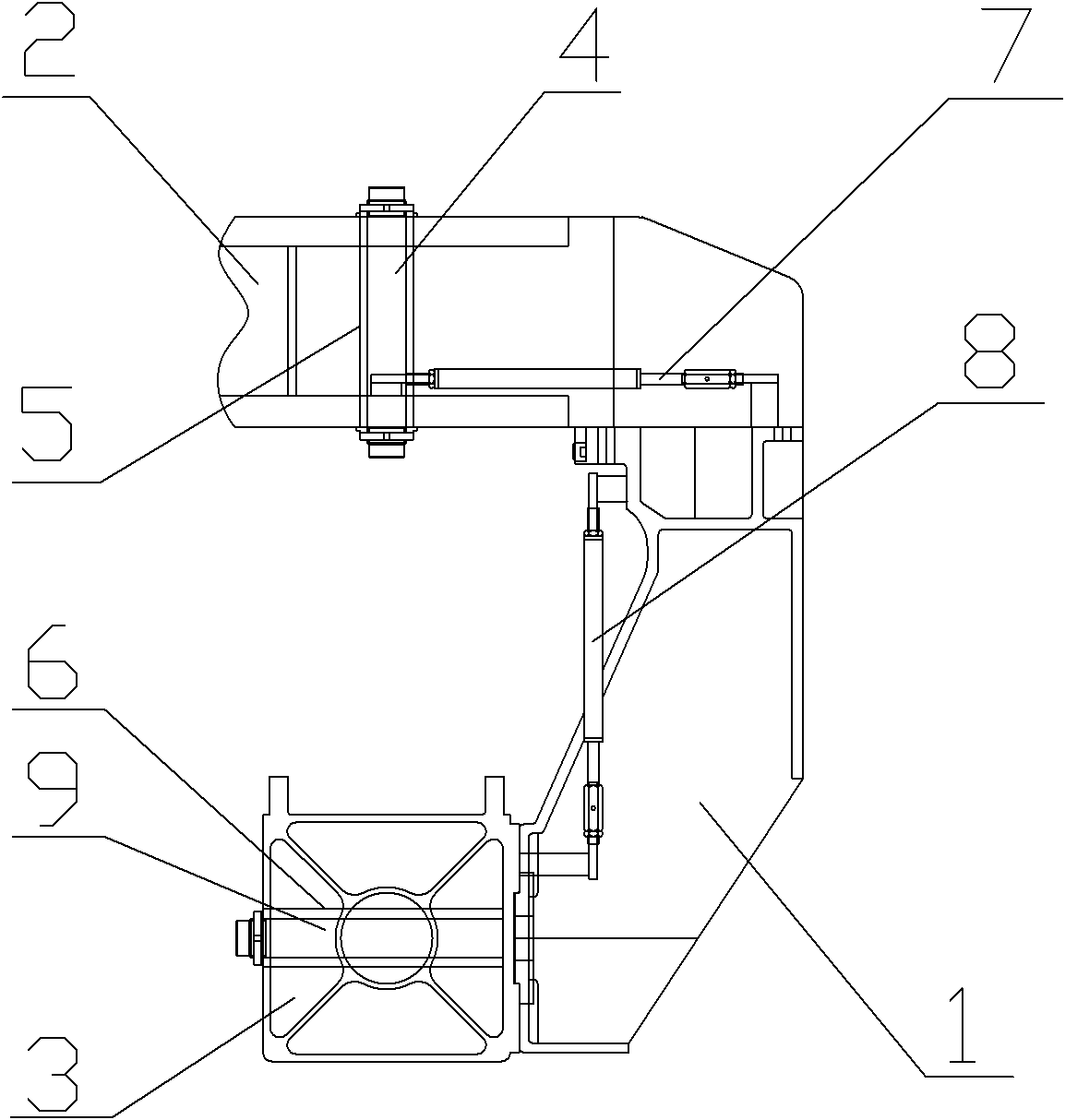

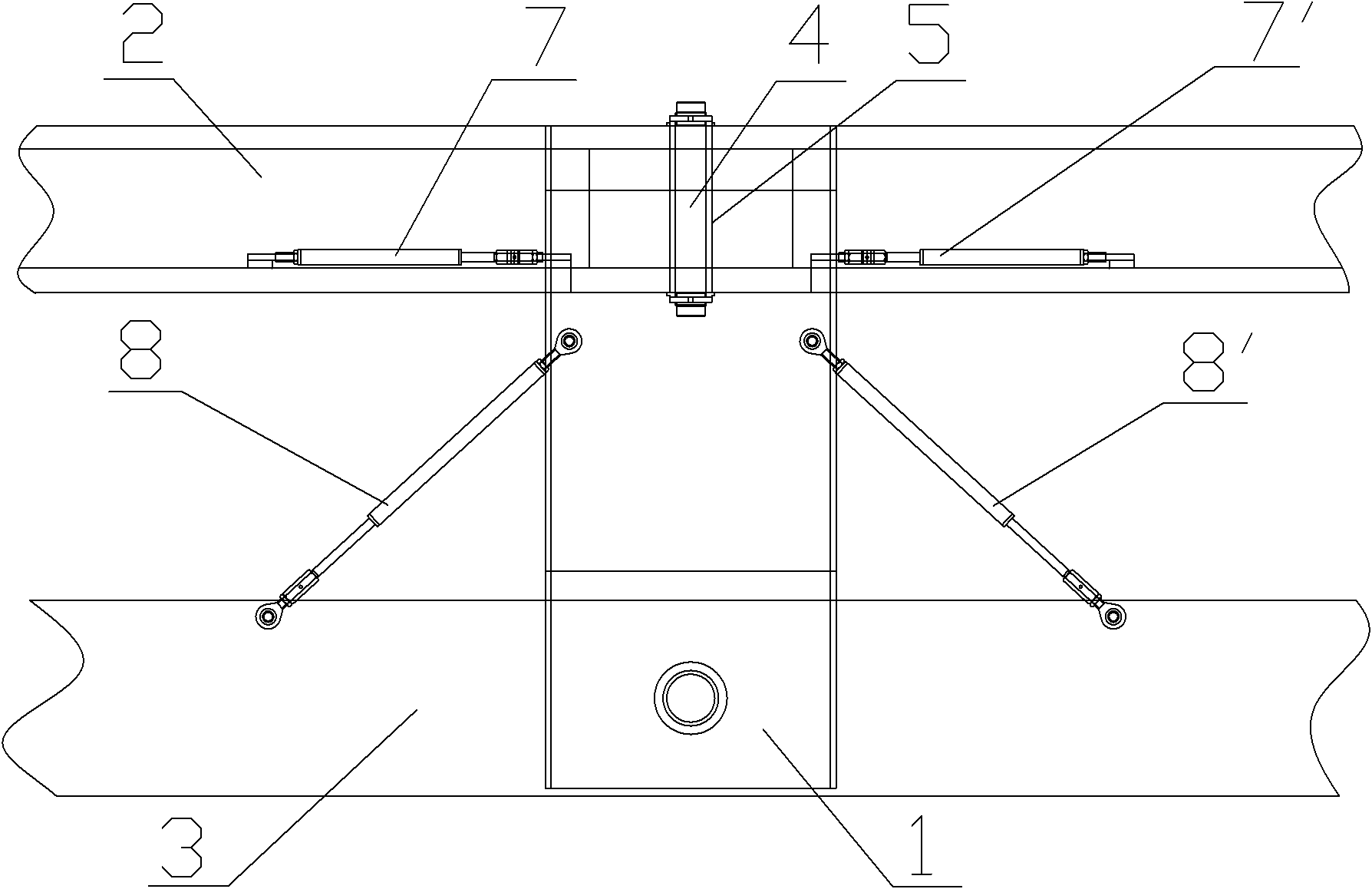

[0013] Such as figure 1 , figure 2 As shown, the movable cantilever structure of the maglev train of the present embodiment includes a C-shaped cantilever bracket 1, the upper part of the C-shaped cantilever bracket 1 is rotationally connected with the suspension frame frame 2 through the vertical rotating shaft 4, and the lower part is installed with the electromagnet through the horizontal rotating shaft 9. The arm 3 is rotatably connected, the horizontal shaft 9 is perpendicular to the electromagnet installation arm 3, and a pair of transverse damping shock absorbers 7 (7') and a pair of longitudinal damping shock absorbers 8 (8') are arranged on both sides of the C-shaped cantilever support 1. The two ends of the transverse damping shock absorber 7 (7') are respectively connected to the C-shaped cantilever bracket 1 and the suspension frame frame 2, and the two ends of the longitudinal damping shock absorber 8 (8') are respectively connected to the C-shaped cantilever bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com