Biaxial uniform-thickness circular vibrating screen

A circular vibrating screen, equal thickness technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of slow feeding, low screening efficiency, unfavorable material screening, etc., to improve screening efficiency and reasonable structure. , the use of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

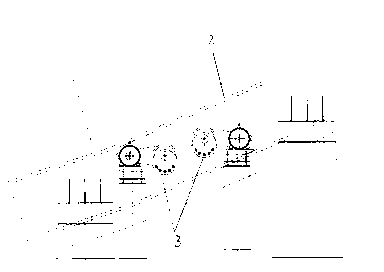

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. The specific embodiment of the present invention is a biaxial equal-thickness circular vibrating screen, which includes a screen body 1, a screen plate 2, and two exciters 3 are installed in the middle of the screen body. The sieve plate on the upper part of the vibrator adopts a three-stage inclination design. The angle between the sieve plate installed at the feed inlet and the horizontal plane described in this embodiment is preferably more than 30 degrees. The large sieve plate can ensure that when the material enters from the feed port, the material is not easy to accumulate, travels faster, and the screening efficiency is higher. The angle between the middle sieve plate and the horizontal plane is small, preferably about 20 degrees, and the material is more stable. For sufficient screening time, the angle between the sieve plate at the discharge port and the horizontal plane is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com