Rigid-connection node of combined steel-pipe concrete column and steel beam

A steel tube concrete column, combined technology, applied in the direction of construction, building structure, etc., can solve problems such as engineering hidden dangers, difficulty in making inner partitions, affecting concrete pouring and strength in tubes, etc., to achieve direct force transmission of nodes and construction convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

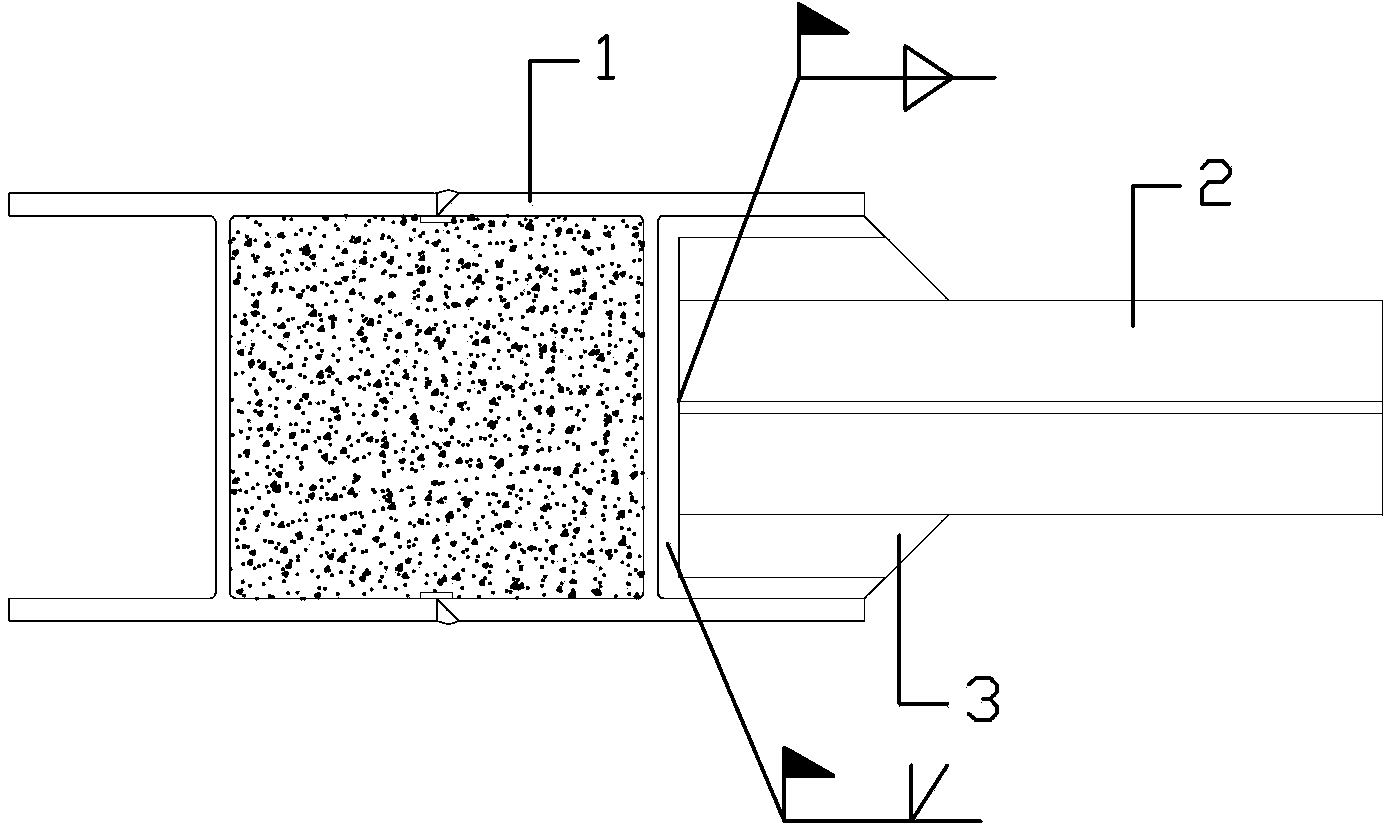

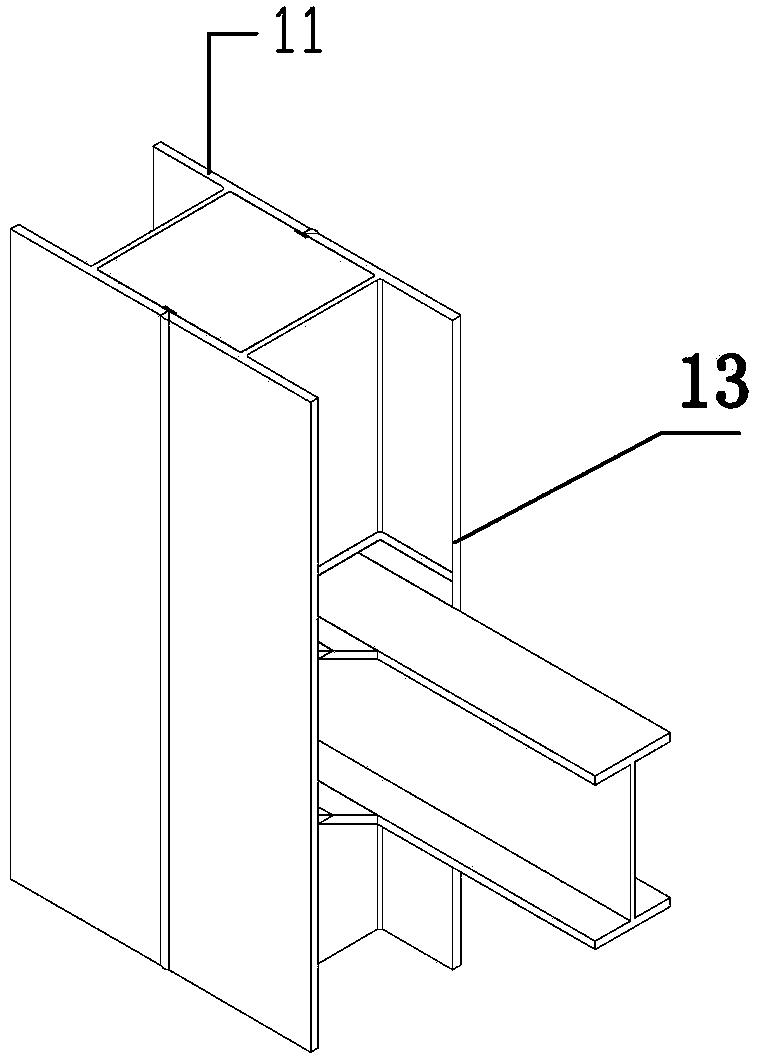

[0026] Refer to attached Figure 1-2 , a rigid connection joint between a composite steel pipe concrete column and a steel beam, including a composite steel pipe concrete column 1 and a steel beam 2, the composite steel pipe concrete column includes two "H" shaped steel 11, the two The two section steels are vertically arranged and welded together through the flange; the web of the section steel is provided with shear studs along the height direction, and concrete 1 is poured in the cavity surrounded by the splicing of the two section steels, and the concrete and the section steel are passed through the The above-mentioned shear studs are connected together; the combined concrete-filled steel tube column is provided with vertically arranged side plates, the steel beam is arranged between the two side plates, and the flanges of the adjacent combined steel-filled steel tube concrete column ends of the steel beam face upward There is a horizontal connecting plate 3 extending in t...

Embodiment 2

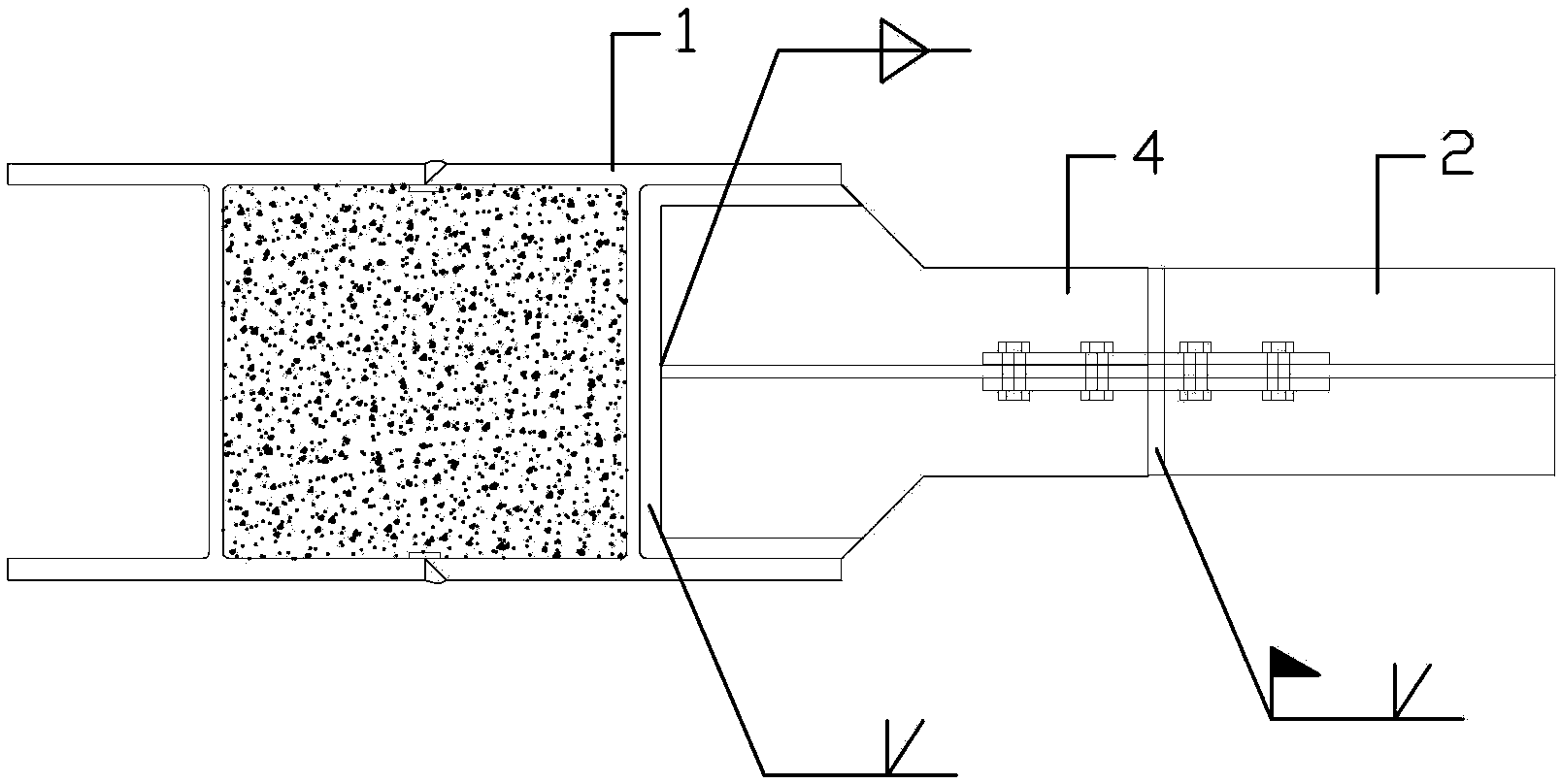

[0028] Refer to attached Figure 3-4 , a rigid connection joint between a composite steel pipe concrete column and a steel beam, including a composite steel pipe concrete column 1 and a steel beam 2, the composite steel pipe concrete column includes two "H" shaped steel, the two The shaped steel is vertically arranged and welded together through the flange; the web of the shaped steel is provided with shear studs along the height direction, and concrete is poured into the cavity formed by the splicing of the two shaped steels, and the concrete and shaped steel pass through the anti- The shear studs are connected into one; the combined concrete-filled steel pipe column is provided with a vertically arranged side plate, and the steel beam is connected to a corbel 4 close to the end of the combined steel-filled concrete column, and the corbel is adjacent to the combined-type concrete-filled steel tube A horizontal connecting plate extends from the flange of the column end toward ...

Embodiment 3

[0030] Refer to attached Figure 5-6 , the steel beams are arranged on one side of the two steel flanges, and the side plate 5 is welded to the steel flanges. The steel beam is welded H-shaped steel. The welds between the flanges of the steel beams and the horizontal connecting plates and the composite steel pipe concrete columns and their side plates are connected by fillet welds, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com