A kind of integral underground wall construction method

A construction method and integrated technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of reduced wall quality, reduced gripping force, mud pollution, etc., to improve engineering safety and reduce material costs. , the effect of safety in the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

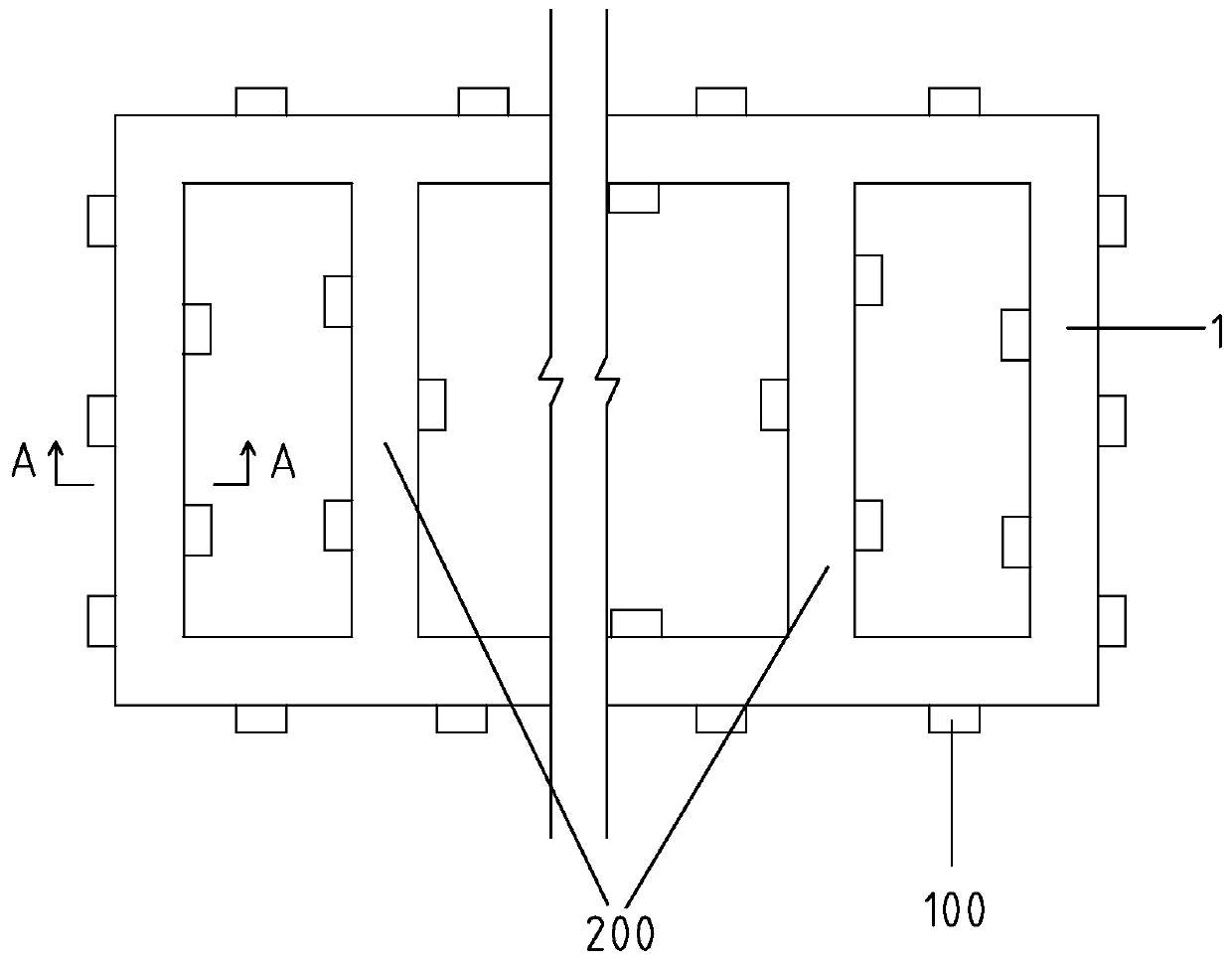

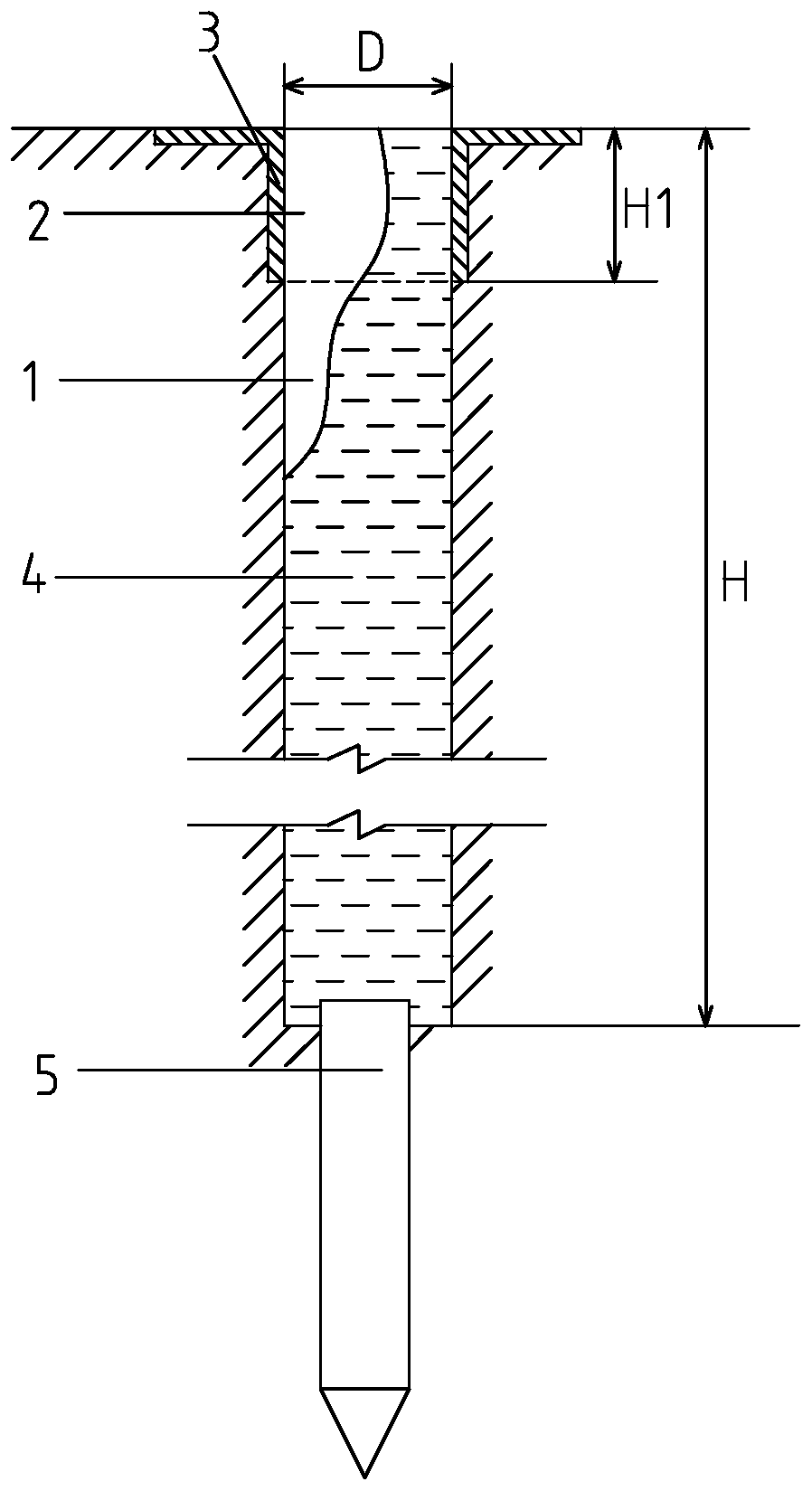

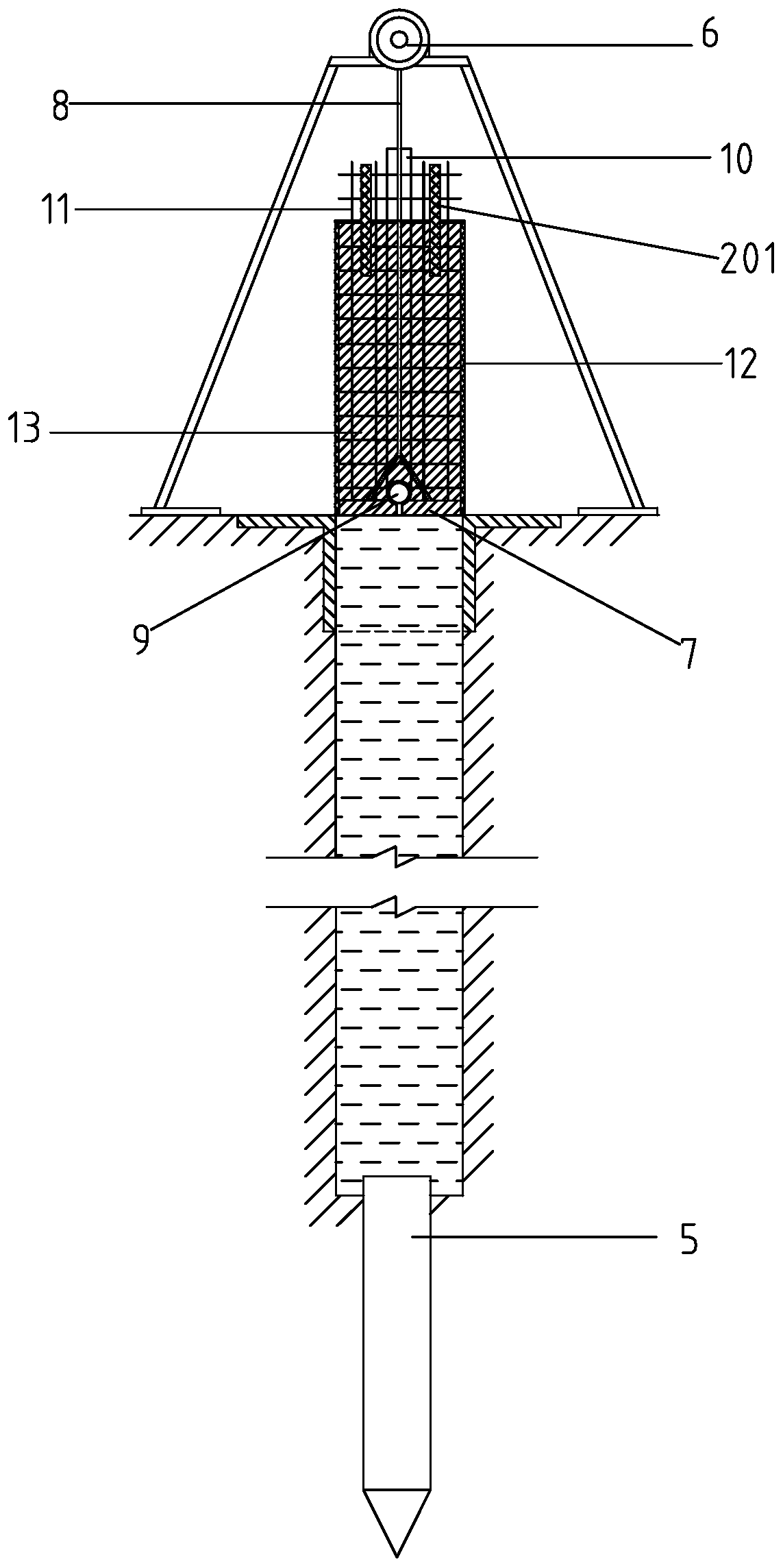

[0040] Such as figure 1 with figure 2 A kind of integral underground wall construction method shown, comprises the following steps: a, slotting, slotting on the ground by slotting machine, open the groove 1 that predetermined depth is H, width is D, in this embodiment by figure 1 Take the back-shaped groove shown in as an example, step a includes the following steps: a1, positioning and setting out: set the positioning point at the track of the groove to be opened on the ground, connect the positioning point with the positioning line to form the groove track, and Sprinkle gray lines along the positioning line to form a groove track; a2. Use a slotting machine to open a mud guide groove with a depth of H1 and a width of D along the groove track. The ratio of the depth H1 of the mud guide groove to the predetermined depth H is 0.07 -0.15; a3. Concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com