FRP-UHPC combined bridge deck slab with open stiffening ribs

A technology of FRP-UHPC and stiffeners, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of low material utilization rate, low bridge deck stiffness, low elastic modulus, etc., and achieve high material utilization rate and construction production Convenience, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

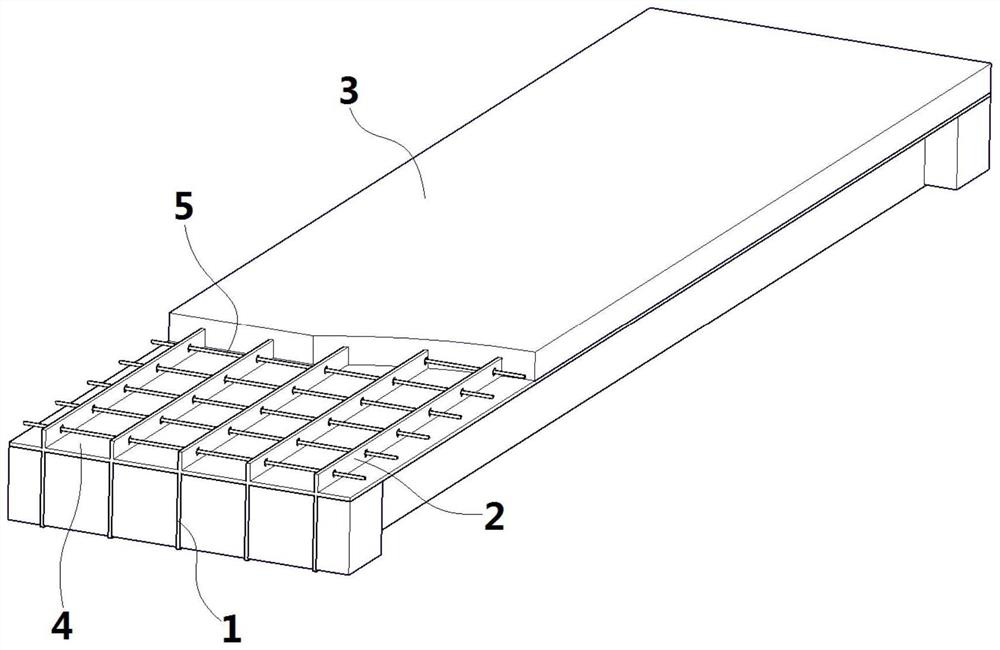

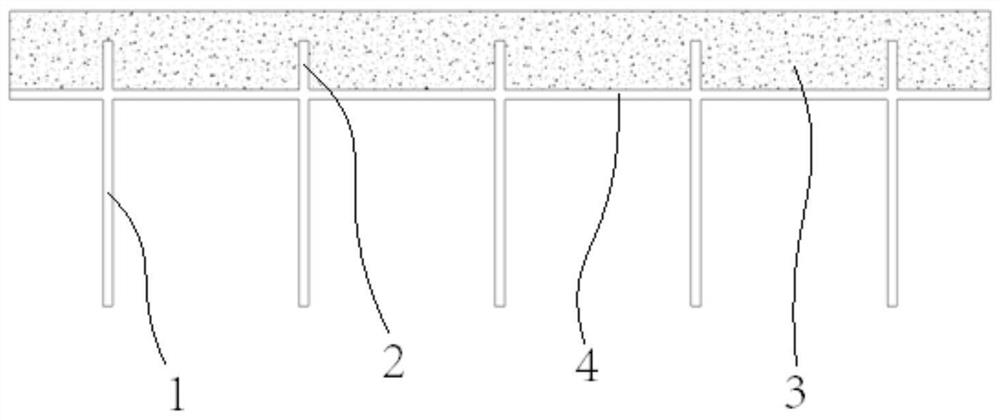

[0031] This embodiment discloses an FRP-UHPC composite bridge deck with open stiffeners. The deck is a unidirectional plate with a width greater than or equal to 600 mm, so as to avoid an increase in processing and installation workload caused by laying too many plates along the entire length of the bridge. An FRP-UHPC composite bridge deck with open stiffeners, including FRP profile and UHPC layer 3.

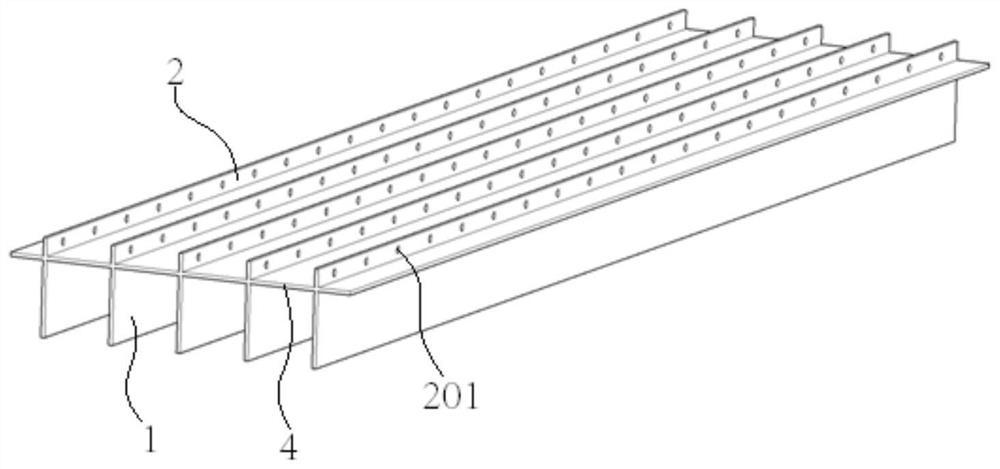

[0032] The FRP profile is integrally pultruded, see 1 or 2, the FRP profile includes an FRP opening stiffener 1, an FRP perforated plate 2 and an FRP horizontal plate 4, and the FRP horizontal plate 4 is a rectangular plate arranged horizontally.

[0033] Referring to 1 or 2, the upper surface of the FRP horizontal plate 4 is connected with several FRP perforated plates 2, and several FRP perforated plates 2 are arranged at equal intervals along the width direction of the FRP horizontal plate 4, and the length direction of the FRP perforated plates 2 is in line with the The len...

Embodiment 2

[0041] This embodiment discloses an FRP-UHPC composite bridge deck with open stiffeners. The deck is a unidirectional plate and includes FRP profiles and a UHPC layer 3 .

[0042] Referring to 1 or 2, the FRP profile includes an FRP open stiffener 1, an FRP perforated plate 2 and an FRP horizontal plate 4, the FRP horizontal plate 4 is a rectangular plate arranged horizontally.

[0043] Referring to 1 or 2, the upper surface of the FRP horizontal plate 4 is connected with several FRP perforated plates 2, and several FRP perforated plates 2 are arranged at equal intervals along the width direction of the FRP horizontal plate 4, and the length direction of the FRP perforated plates 2 is in line with the The length direction of the FRP horizontal plate 4 is consistent, and the two ends of the FRP perforated plate 2 in the length direction are respectively flush with the edges on both sides of the FRP horizontal plate 4 in the length direction.

[0044] see figure 1 , the FRP per...

Embodiment 3

[0048] The main structure of this embodiment is the same as that of Embodiment 2, furthermore, the distance between two adjacent FRP open stiffeners 1 is less than or equal to 0.2m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com