A high-precision underground wall construction method

A construction method and high-precision technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as poor quality and low precision, and achieve the effects of convenient construction and manufacturing, high precision, and anti-tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

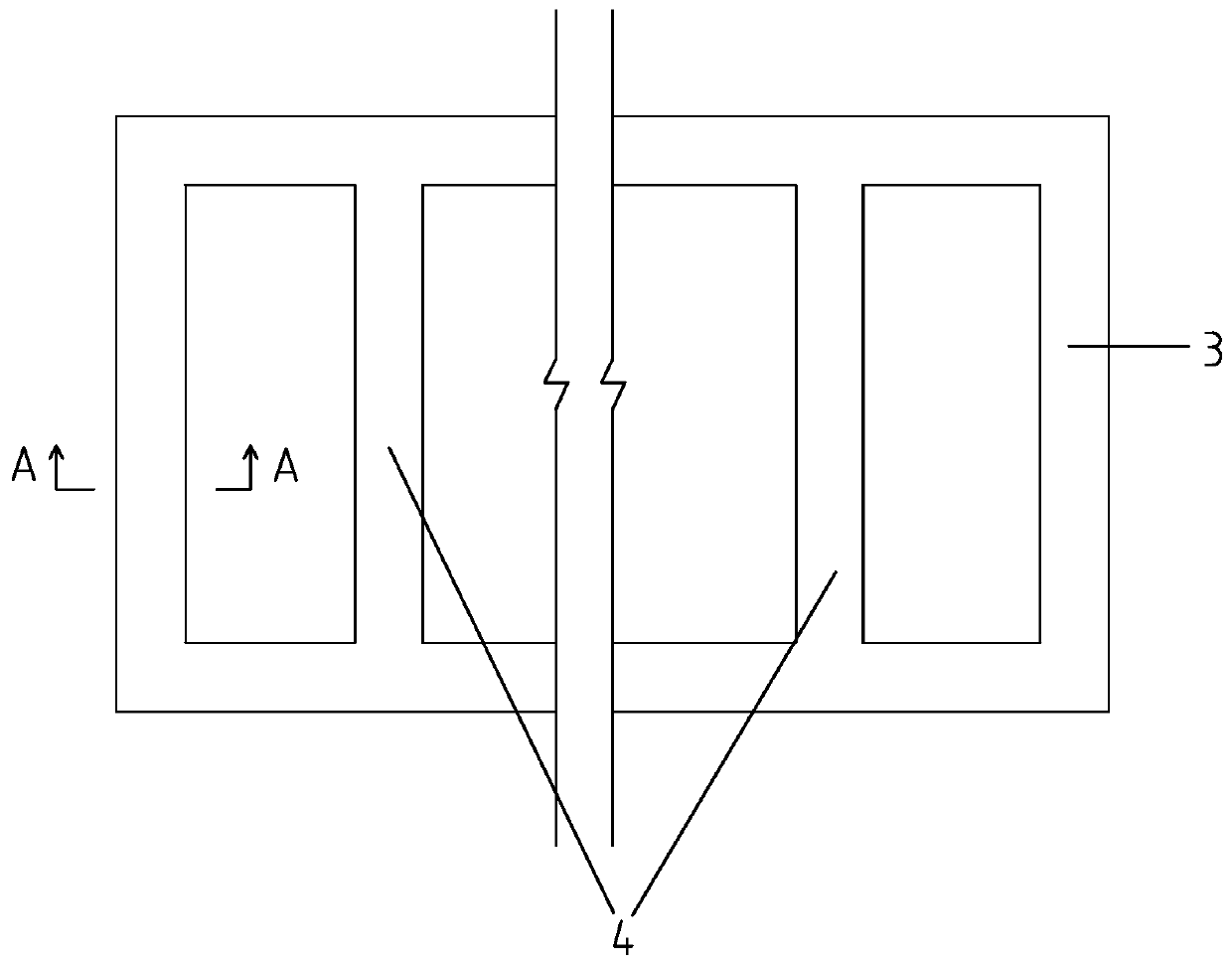

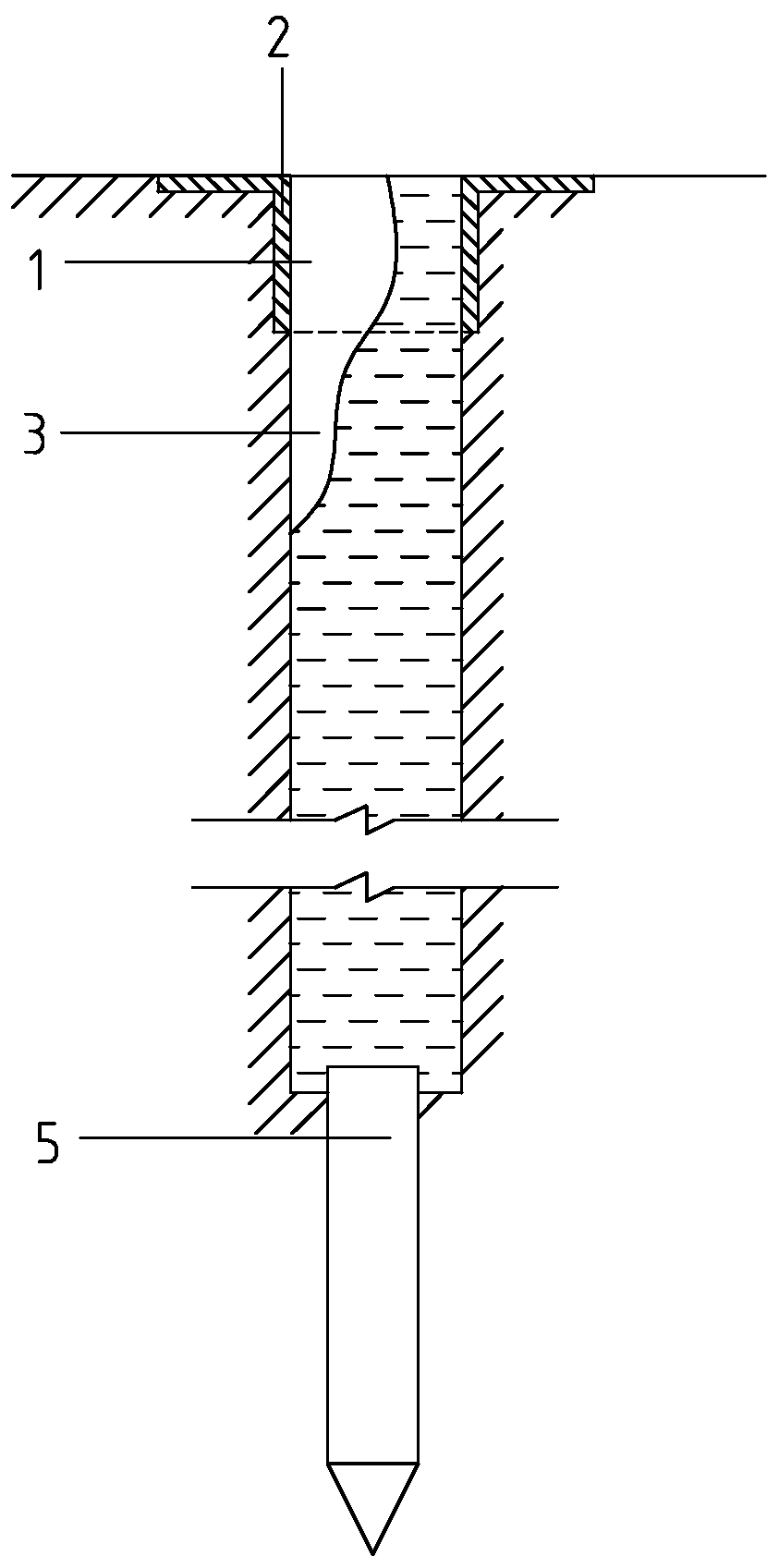

[0030] like figure 1 and figure 2 A high-precision underground wall construction method shown includes the following steps: use a slotting machine to open a mud guide groove 1 on the ground, set a guide wall 2, open a groove 3 at the bottom of the mud guide groove, and prepare a density in the groove 1.4g / cm 3 -1.7g / cm 3 The mud, in this example to figure 1 Take the back-shaped groove shown in as an example, when opening the groove, open the supporting beam avoidance groove 4 together.

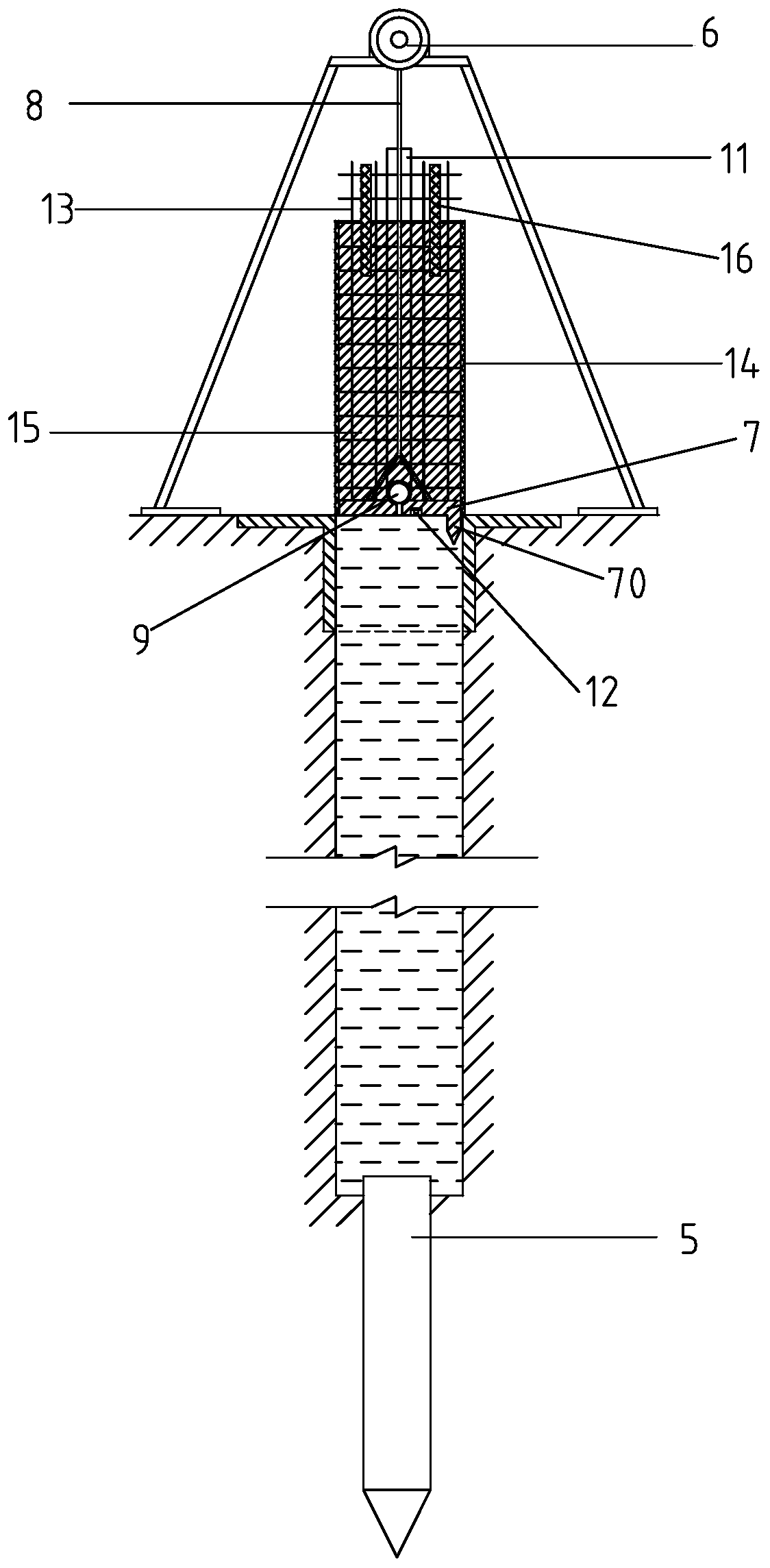

[0031] like image 3 , Figure 4 and Image 6 As shown, a number of anti-sinking piles 5 are implanted at the bottom of the groove 3, the top surfaces of the anti-sinking piles are coplanar, and the distance between the top surface of the anti-sinking piles and the bottom of the groove is 4cm-6cm; A number of cranes 6 are installed above, and a support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com