Demolding device of plastic tray injection mold fork insert

A technology for injection molds and plastic trays, which is applied in the field of demoulding devices for fork mouth inserts of plastic tray injection molds, and can solve problems such as defects, lack of cooling water, and impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

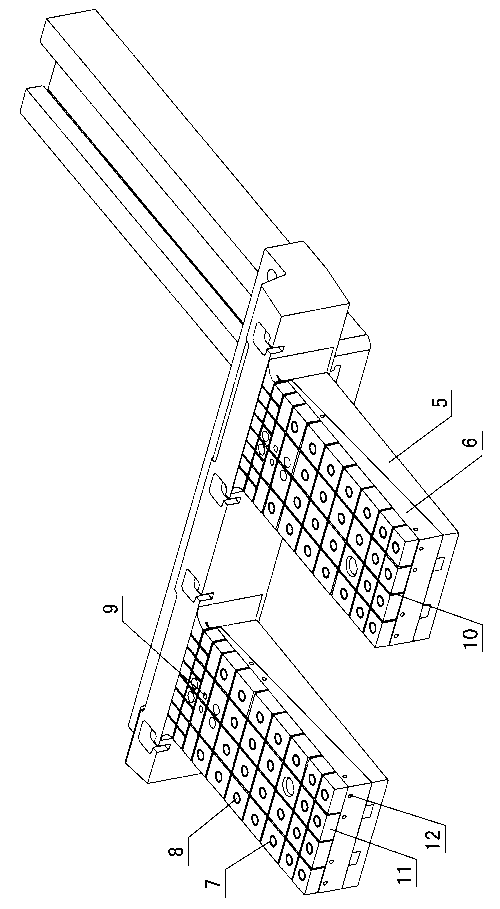

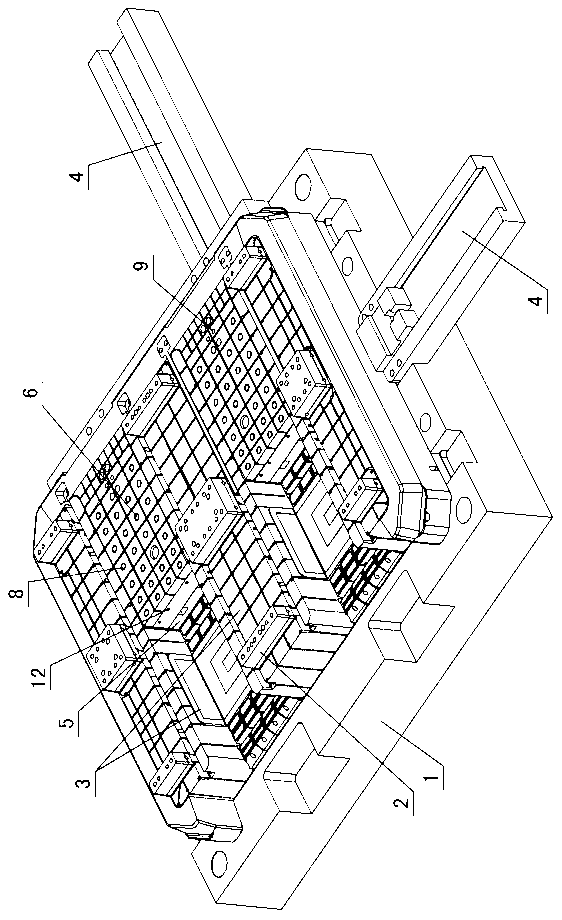

[0008] The invention relates to a demoulding device for a fork insert of a plastic pallet injection mold, such as figure 1 — figure 2 As shown, it includes a core fixing plate 1, a small plate-foot insert 2 and a plate-foot large insert 3 are installed on the core fixing plate, a slider groove 4 is installed on the side wall of the core fixing plate, and a fork is set on the slider groove The mouth slider 5 has a fork insert 6 on the fork slide, and the fork insert is shaped on a rib groove 10 and a square hole block 11, and is characterized in that the side wall of the fork insert has an air inlet 12 On each square hole block 11 of the fork insert 6, an air valve hole 7 is arranged, and an air valve 8 is installed in the air valve hole. A cooling water circuit is provided in the fork insert 6, and the cooling water channel has a cooling water hole 9. By opening a valve hole 7 on each square hole block 11 of the fork insert 6, a valve 8 is installed in the valve hole. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com