Damper with automatic damping adjusting function

An automatic adjustment, shock absorber technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems that big and small things cannot be changed, the damping of shock absorbers cannot be adjusted, etc., to avoid excessive elastic recovery. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

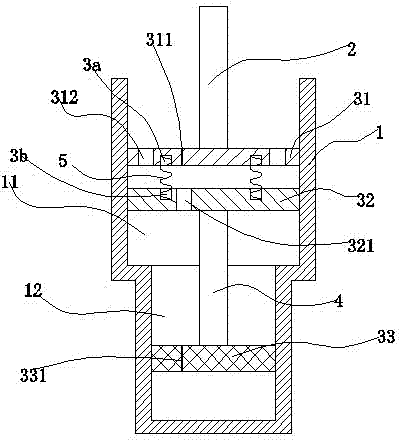

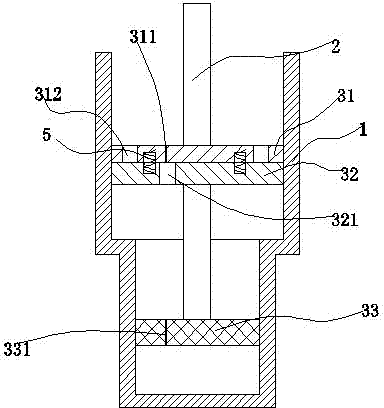

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a shock absorber with automatic damping adjustment, including a cylinder 1 and a piston rod 2, the inner wall of the cylinder at least includes a first cavity 11 and a second cavity 12 with different diameters, and a first piston is slidably connected in the first cavity 11 31 and the second piston 32, the third piston 33 is slidably connected in the second cavity 12, the first piston 31 and the third piston 33 are provided with damping holes 311 and 331, the first piston 31 is provided with a first through hole Air holes 312, the second piston 32 is provided with a second vent hole 321, the damping hole 311 provided on the first piston 31 intersects the projection on the horizontal plane of the second vent hole 321 provided on the second piston 32, the first piston 31 A spring 5 is arranged between the second piston 32, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com