Screwed bolt positioning chimney

A chimney, combined technology, applied in the field of double-layer stainless steel thermal insulation chimneys, can solve the problems such as the failure of the bite hook to achieve the full waterproof function, the imperfect curling bite structure, and the reduction of the thermal insulation performance of the chimney, so as to facilitate the confirmation of installation in place. Work, save the flanging process, reduce the effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

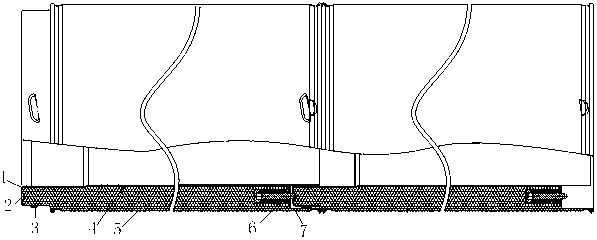

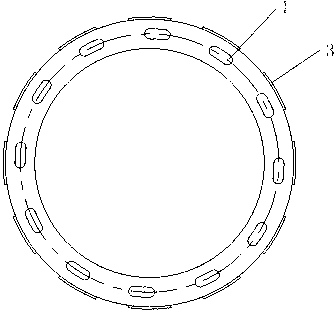

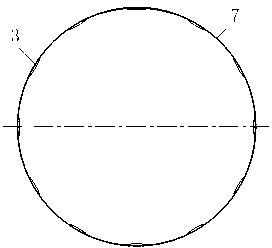

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the chimney is positioned by the screw-in type bolt, which consists of an inner pipe 4 and an outer pipe 5. There is a gap between the inner pipe 4 and the outer pipe 5 and an insulation layer is arranged in the gap. The top and bottom ends of the double-layer stainless steel heat preservation chimney are A head cover 1 and a bottom cover 7 are provided respectively, one side wall of the head cover 1 is welded and fixed with the inner tube 4, the other side wall of the head cover 1 is fixed with the outer tube 5 through crimping, and the outer side of the head cover 1 The wall has at least eight screwing teeth 3 evenly distributed along the circumference, and the same number of pits 2 as the screwing teeth are uniformly distributed on the surface of the head cover 1 along the circumference, and the position of the pits 2 is the same as that of the screwing teeth. 3 are in the same position, one side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com