A method for checking the clogging of sat vaporization valve

A technology of vaporization valves and test pieces, which is applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of excess, high cost, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

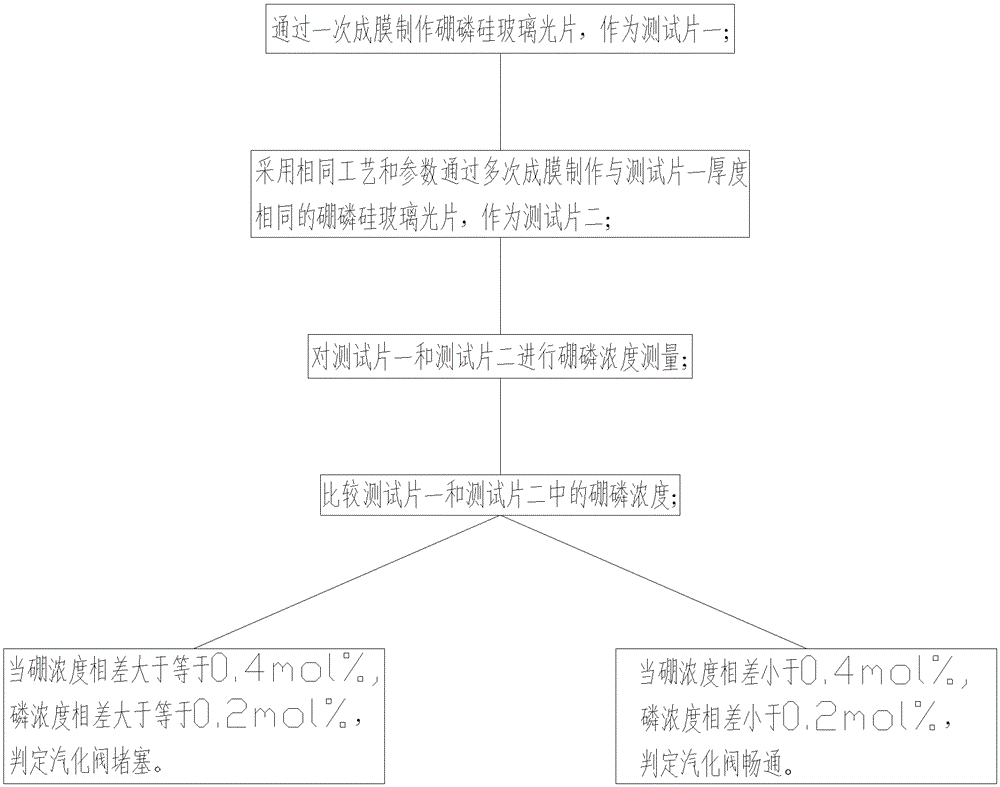

[0024] Such as figure 1 Shown, inspection method of the present invention, in process parameter: temperature: 480 DEG C; Pressure: 200 torr; Gas: helium: 6000 milliliters / minute, ozone: 4000 milliliters / minute, TEOS (diethyl orthosilicate): 600 mg / min, TEB (triethylboronic acid): 100 mg / min, TEPO (triethyl phosphate): 50 mg / min, including the following steps:

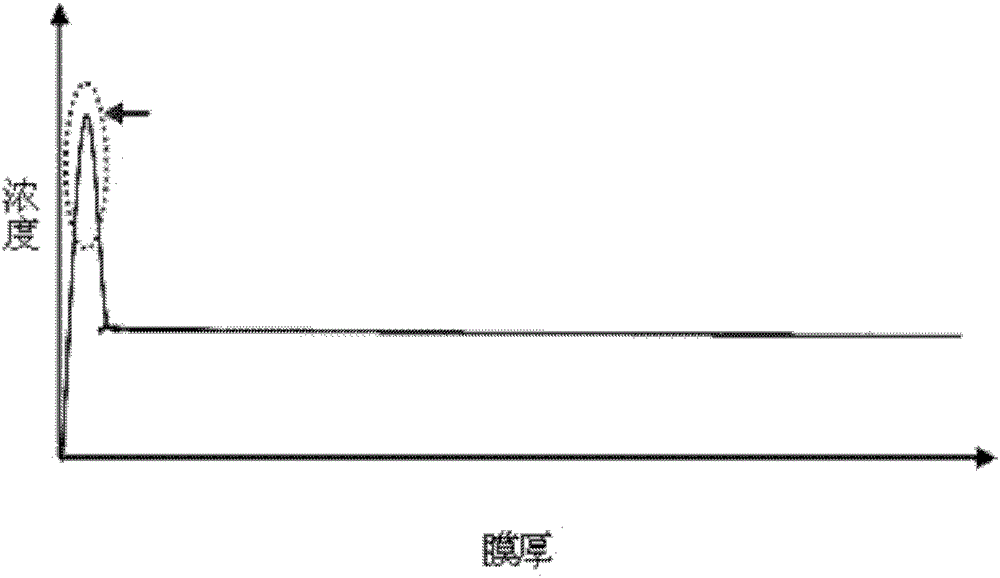

[0025] (1) if figure 2 As shown, through one film formation and a growth time of 100 seconds, borophosphosilicate glass test piece 1 was produced;

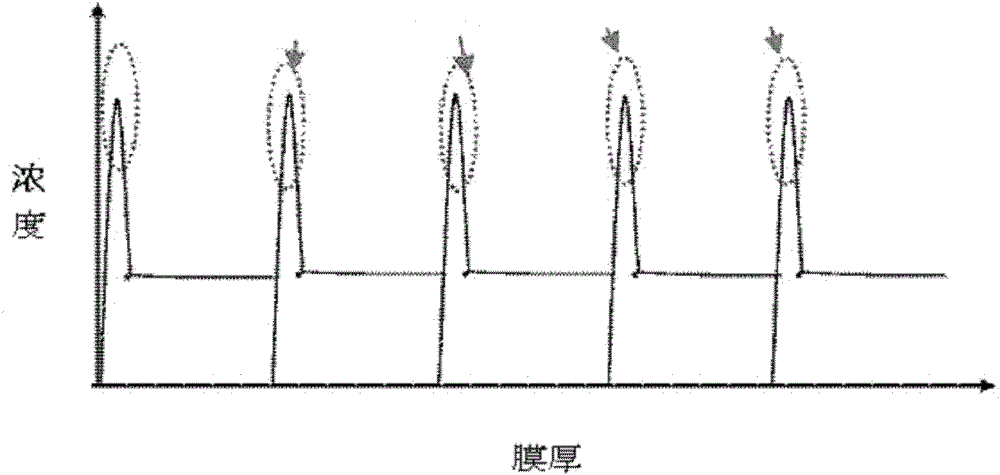

[0026] (2) if Figure 4 As shown, through five times of film formation, each film formation time is 20 seconds, and a borophosphosilicate glass test piece 2 having the same thickness as the test piece 1 is produced;

[0027] (3) measure the boron phosphorus concentration of test piece one and test piece two with concentration tester XRF3640;

[0028] (4) compare the boron phosphorus concentration in test piece one and test piece two;

[0029] When the boron concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com