Passive monitoring method and system for blockage of feed hopper of spent fuel dissolver

A passive monitoring and feeding hopper technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that personnel cannot approach monitoring and high radioactivity levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

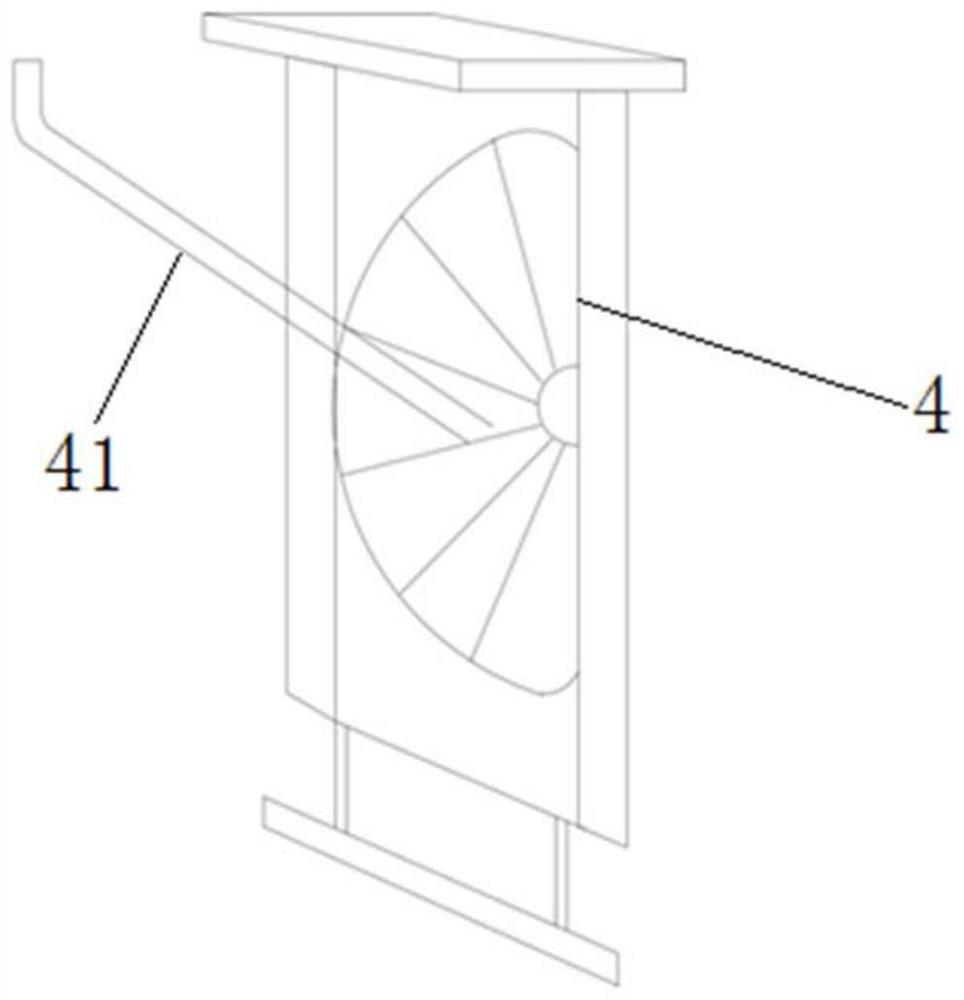

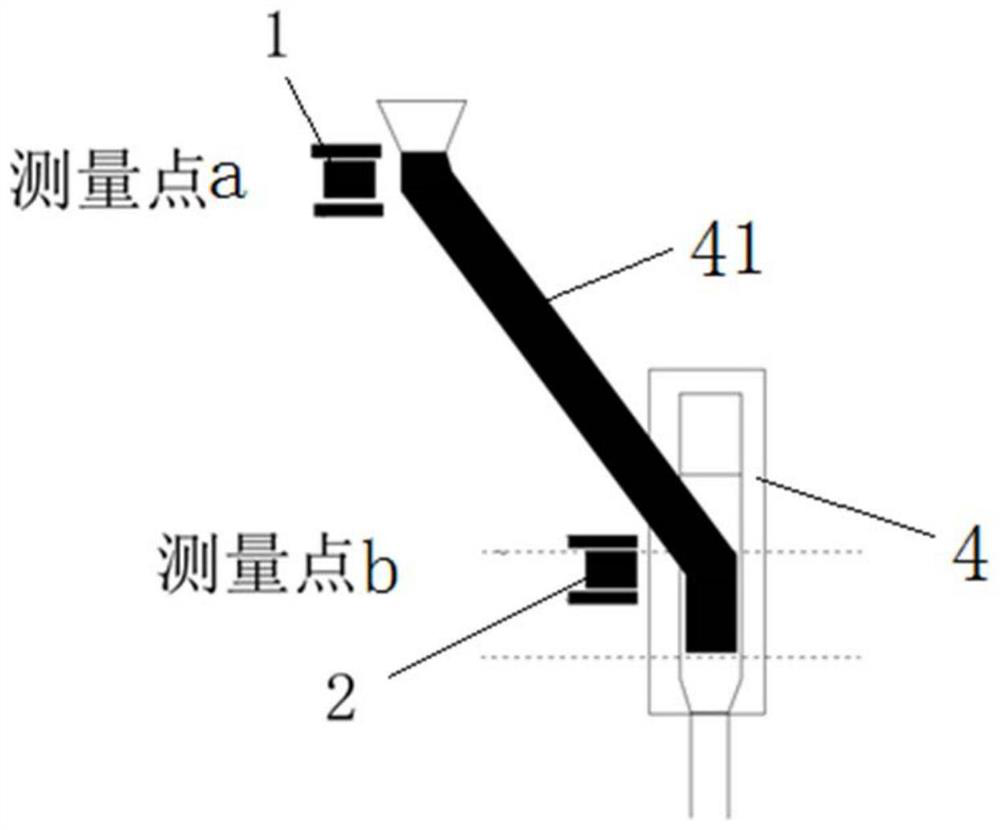

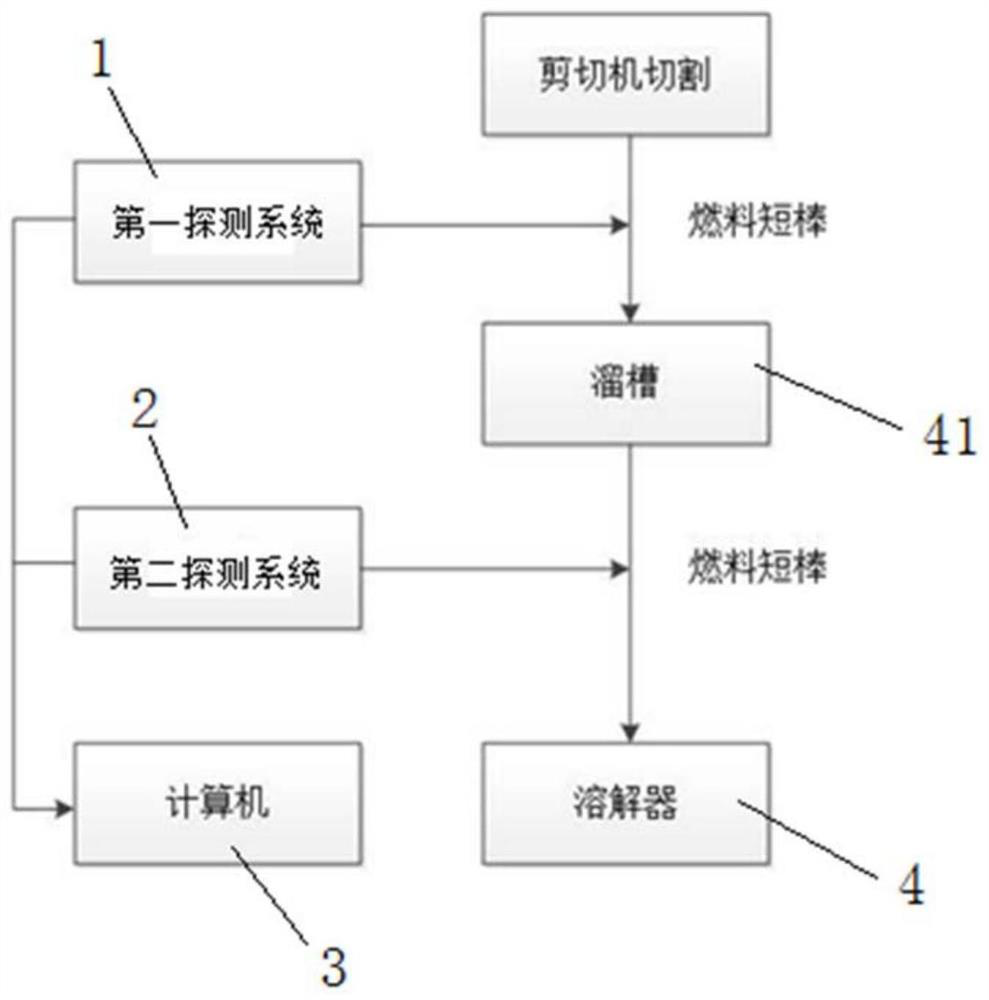

[0064] During the feeding process of the dissolver, the fuel rod is cut into several fuel short sections with a length of about 20-50mm by a shearing machine, such as figure 1 and image 3 As shown, the fuel short section falls into the dissolver bucket along the chute.

[0065] This embodiment provides a passive monitoring method for the blockage of the spent fuel dissolver feed hopper, including:

[0066] S1: Install the first detection system 1 near the top of the feed hopper chute 41 of the spent fuel dissolver 4, and install the second detection system 2 near the bottom of the feed hopper chute 41 of the spent fuel dissolver 4,

[0067] S2: When the spent fuel dissolver 4 feeds, the first detection system 1 detects the gamma rays emitted by the short fuel rods passing through the top of the feed hopper chute 41, and obtains the pulse count corresponding to the set energy range of the gamma rays entering it Rate N 1 ; The second detection system 2 detects the gamma rays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com