True triaxial rheological test system

A rheological test, true triaxial technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. To achieve the effect of improving the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

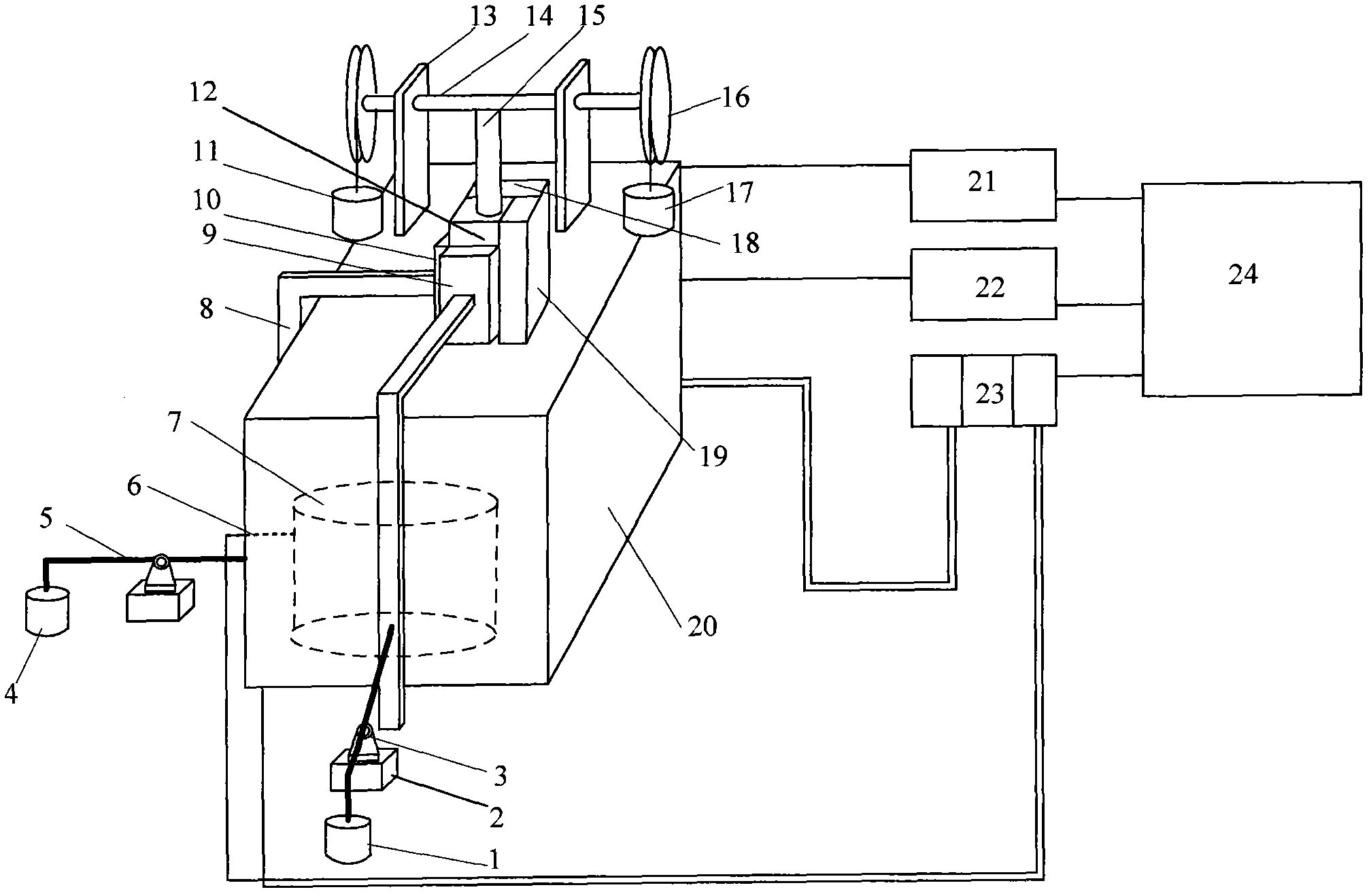

[0018] The present invention is described in detail as follows in conjunction with accompanying drawing:

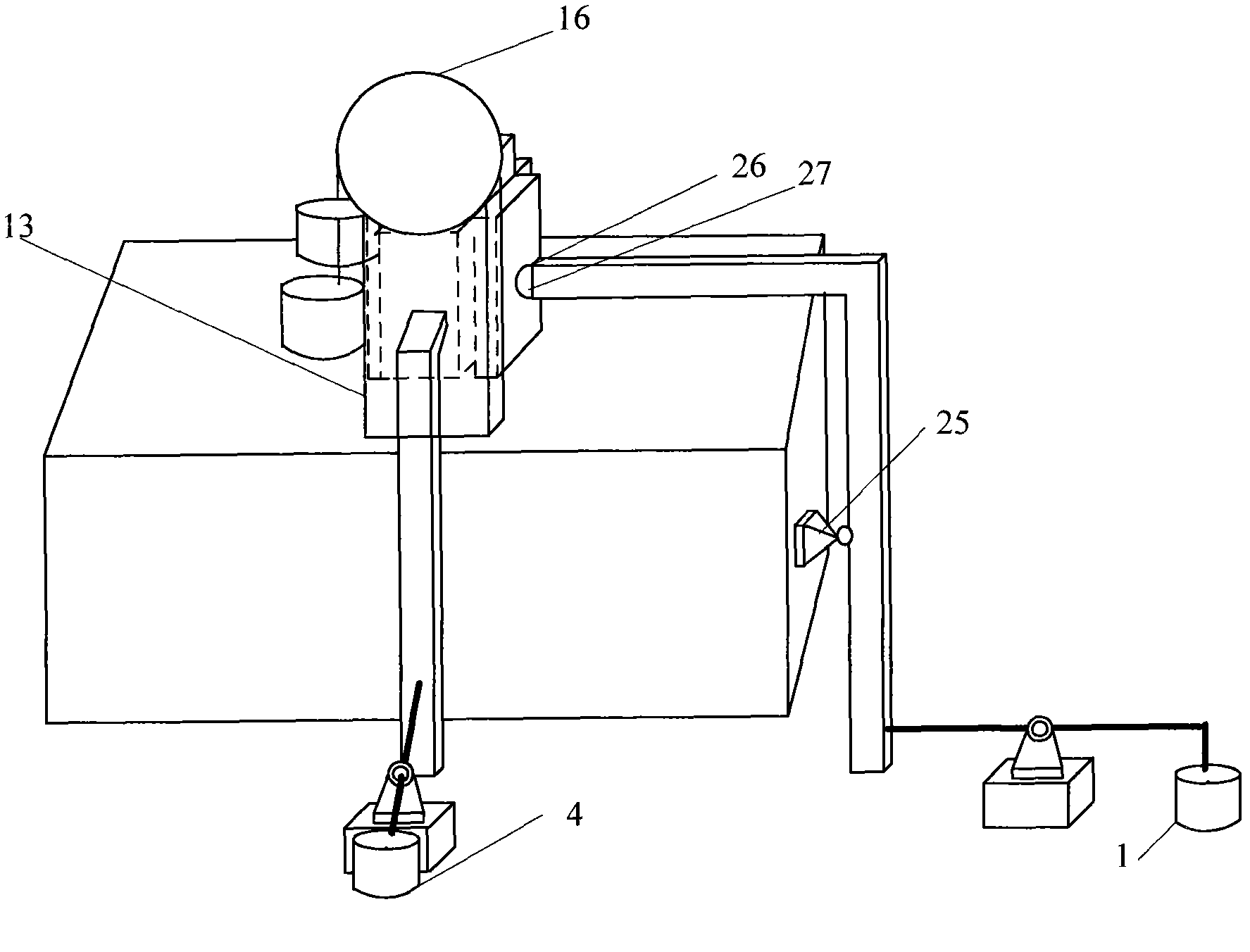

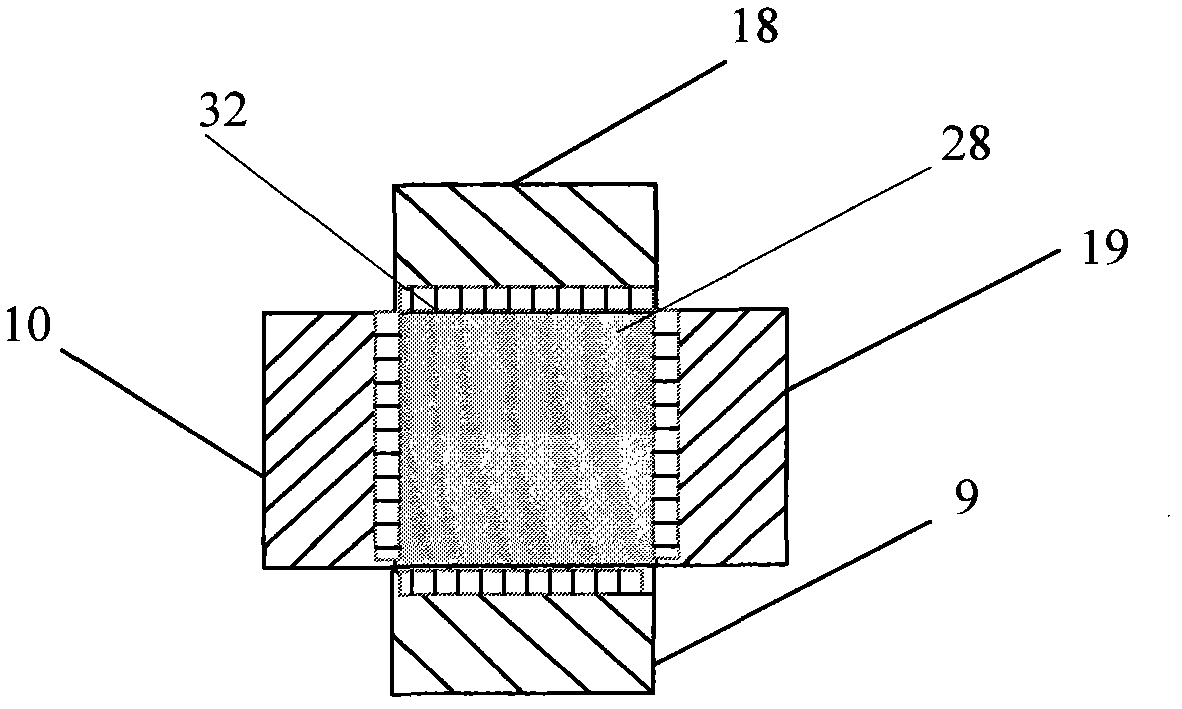

[0019] Loading process: first put the test piece (28) into the semi-open triaxial pressure chamber, start the reciprocating pump (30) to transfer the liquid in the liquid storage tank (7) to the front of the minimum principal stress through the liquid injection pipe (6) Loading weight (1), intermediate principal stress loading weight (4), maximum principal stress left loading weight (11), maximum principal stress right loading weight (17) inject liquid; through three-position four-way solenoid valve (23 ) to control the liquid flow to apply different gravitational loading, and each loading rigid block can be independently controlled; finally, the rheological test is carried out through the expansion force loading of the primary loading lever (5) and the secondary loading lever (8).

[0020] Figure 4 Among them, the control system of the true triaxial rheological test sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com