Installation accessory of steel C channel

A profile and accessory technology, applied in the direction of electrical components, substation/switch layout details, etc., can solve the problems of time-consuming and labor-intensive installation process, large gap between connecting plate and C profile, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

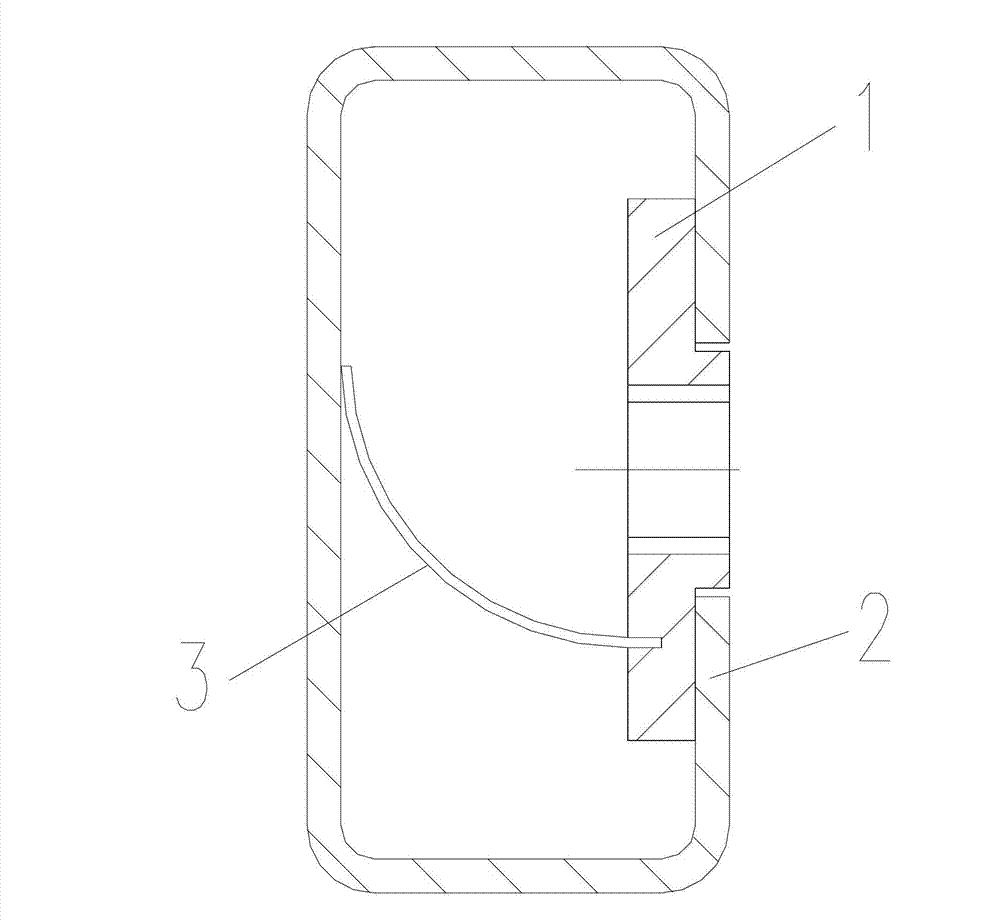

[0008] As shown in the figure, when the C-profile installation accessory of the present invention is installed, the spring or elastic steel sheet and other similar elastic parts 3 on the connection plate 1 make the guide boss of the connection plate 1 be stuck in the notch of the C-shaped groove 2, and the connection The guide boss of the plate 1 guides the connecting plate to move in the groove of the C-shaped material, overcomes the defect that the existing connecting plate needs tools to be straightened when installing components, and improves the installation efficiency of components.

[0009] The description of the above embodiments is relatively specific and detailed, but it should not be interpreted as limiting the patent scope of the present invention. Several variations and improvements can be made, all of which belong to the protection scope of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com