Method of controlling vehicle wheel axle torque and control system for same

A shaft torque, torque limiting technology, applied in the field of direction propulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

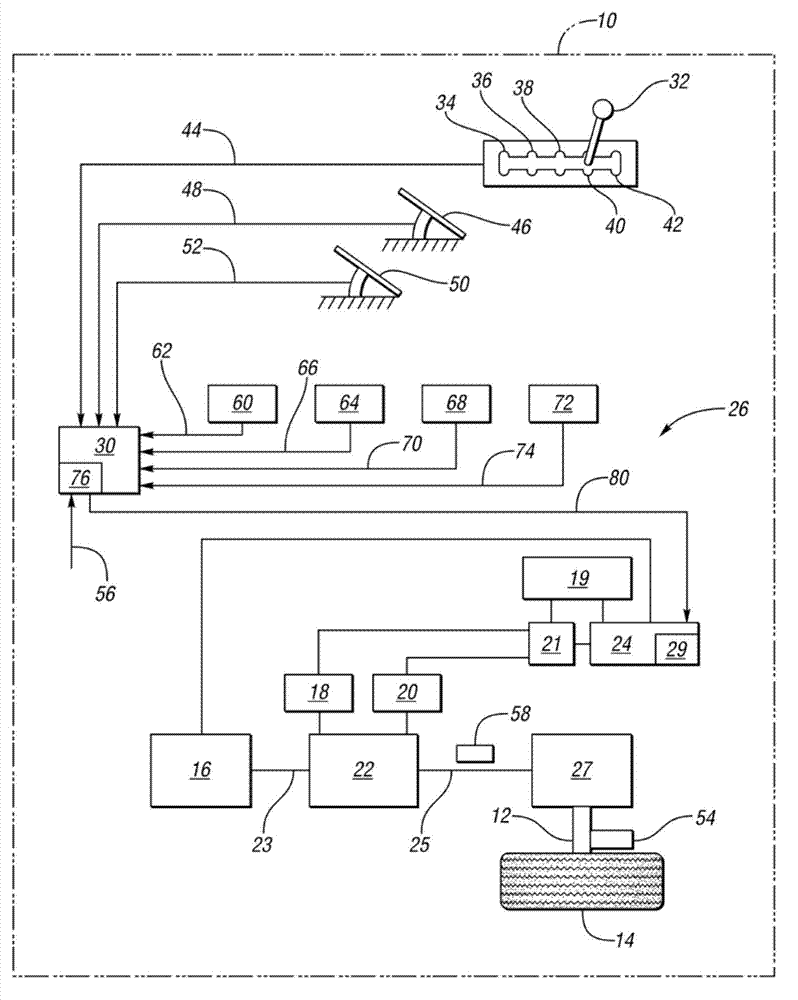

[0016] Referring to the drawings, wherein like reference numerals denote like parts throughout the several views, figure 1 A vehicle 10 is shown being propelled when axle torque is provided to axles 12 of wheels 14 . Only one axle 12 is shown. Vehicle 10 may be a front-wheel drive, rear-wheel drive, or all-wheel drive vehicle within the scope of the claimed invention. As shown, the vehicle 10 is a hybrid vehicle having an engine 16 and two motor / generators 18 , 20 . However, vehicle 10 may alternatively be an electric vehicle, having a motor / generator but no engine, or may be a fuel cell vehicle, having only a fuel cell powering one or more electric motor / generators. The vehicle 10 can have multiple modes of operation, depending on the engagement of clutches or brakes in the transmission 22, and depending on whether the engine 16 is running and whether the motor / generators 18, 20 are each separately controlled to operate as a motor or Runs as a generator.

[0017] The engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com