Leaking stoppage device of pipe hole leakage points

A leakage point and leak stopper technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficult to fill leaks, ineffective plugging of leaks, damage to sealing materials, etc., to achieve Efficient use, great practical value, and the effect of civilized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

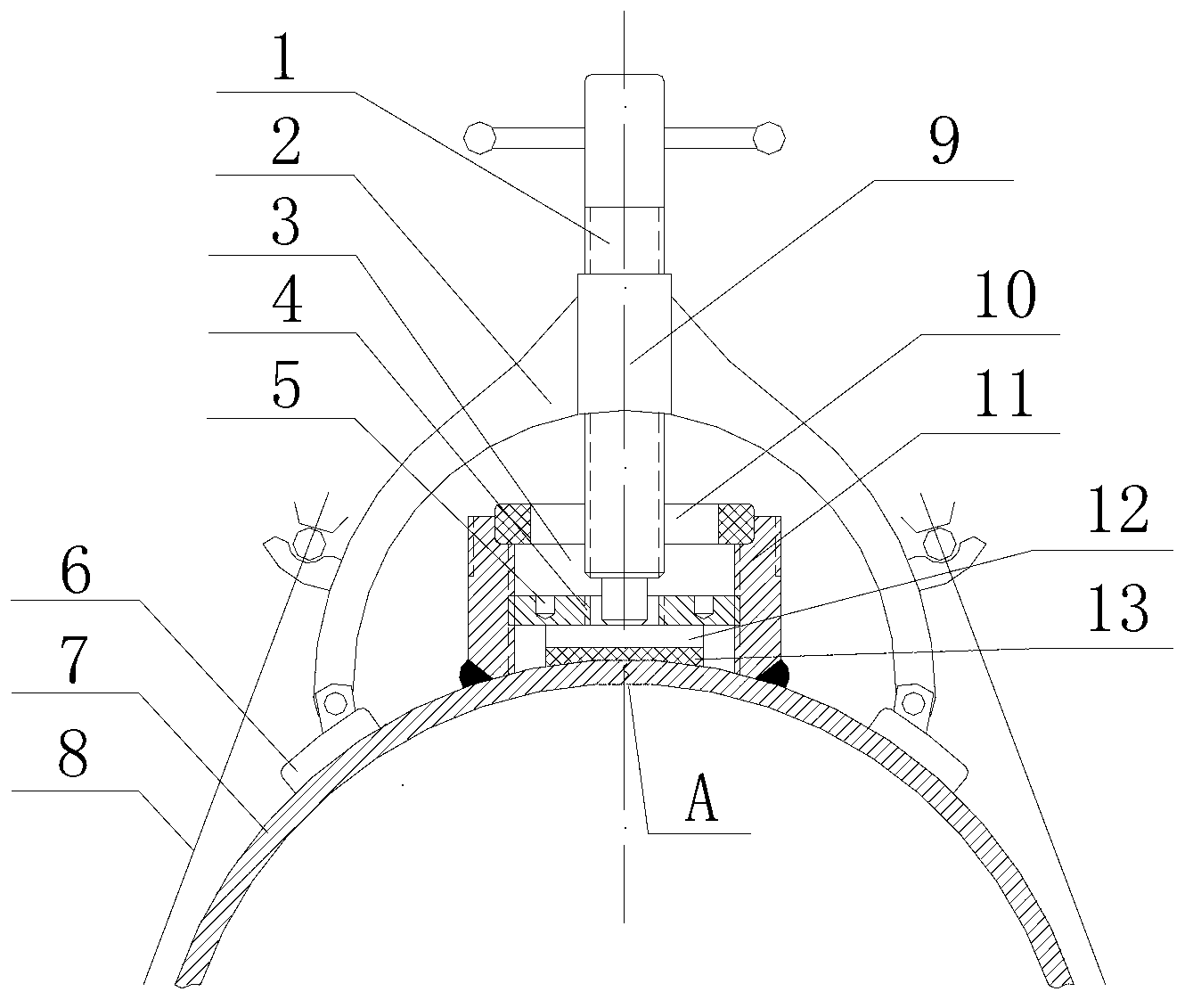

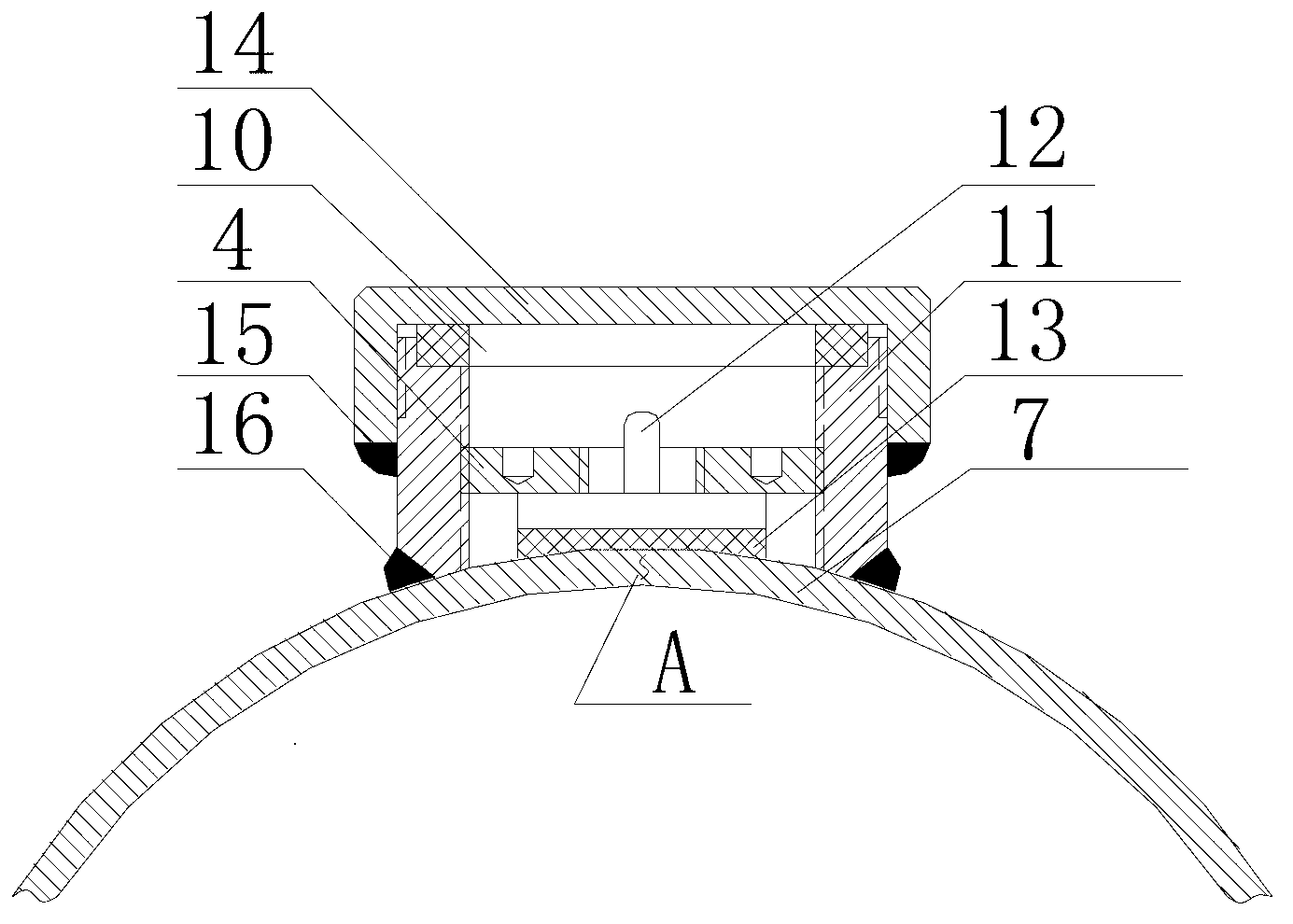

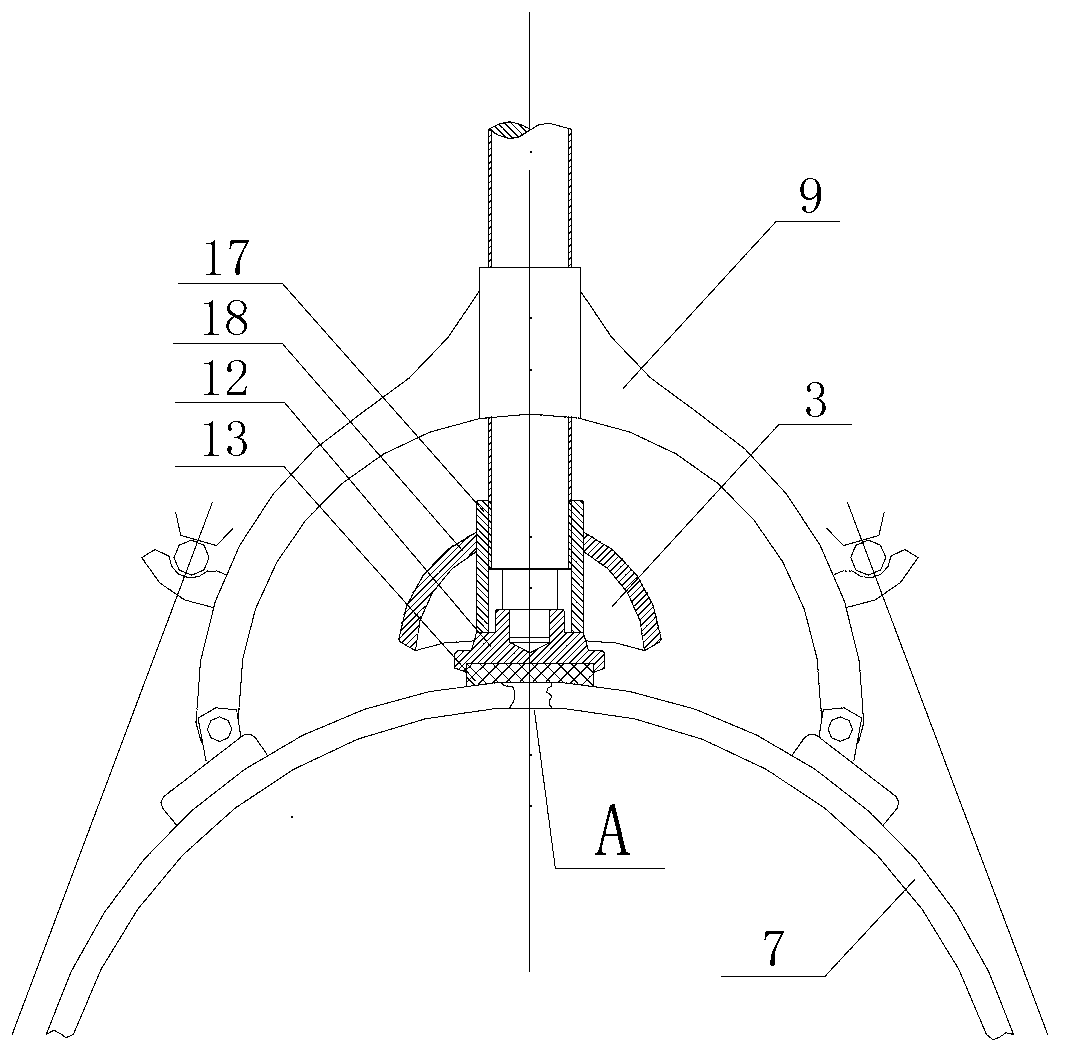

[0019] The leak plugging device for the leakage point of the pipeline hole of the present invention is composed of a fixing frame assembly 9 and a plugging body assembly 3 and the like. Among them: the fixed frame assembly is supported by two points of the arc bracket 2, the detachable tension chain 8 used to fix the arc bracket on the pipeline 7 to be plugged, and rotated in the center of the arc bracket, the axis is vertical It is composed of a lead screw 1 at the center of the pipeline to be plugged; the plugging body assembly includes a plugging body used to connect with the pipeline to be plugged, a compression part that is fixedly connected with the plugging body and has a central hole, and The sealing assembly compressed and fixed by the compressed part and a cover plug used for closing the leakage blocking body. The bottom of the sealing assembly in the plugging body assembly is a flexible sealing gasket 13, and the upper part is a metal pressing bracket 12. The flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com