Aircraft cabin plugging ball

A cabin and aircraft technology, applied to aircraft parts, emergency equipment, transportation and packaging, etc., can solve the problems of safety threats to the cabin personnel, forced landing or high cost of return flight, etc., to ensure safety and comfort, simple structure, and restore air pressure and the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

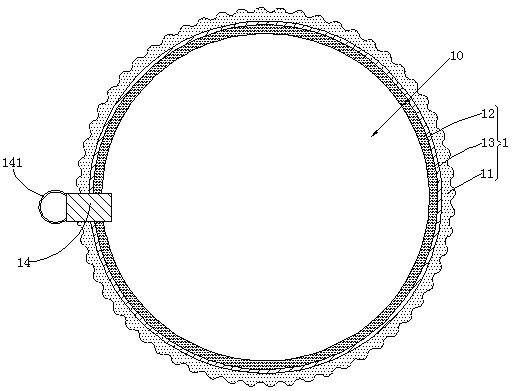

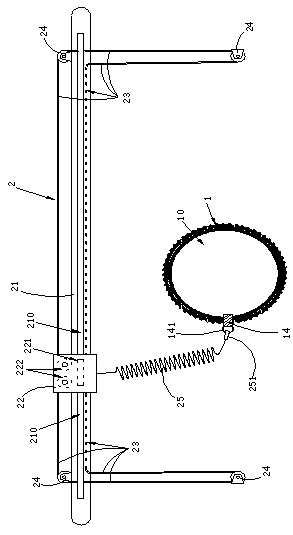

[0019] refer to figure 1 , figure 2 , Aircraft cabin plugging ball, comprises main sphere 1, and the size of main sphere 1 can be equipped with and be filled with gas when diameter is 300mm, 500mm, 1000mm or 2000mm, suitably selects according to breach size and position. More plugging balls of different sizes should be prepared in the cabin. Observe the size of the damaged area, and select a plugging ball with a size larger than the damaged size, such as: the largest damage is 400mm, and a plugging ball with a diameter of not less than 600mm is selected. When the flight altitude changes, the atmospheric pressure will change significantly, so wait until the flight altitude drops to a certain height (below 5000m) before completing the inflation and plugging. From low-altitude flight to landing, the volume of the plugging ball changes, but the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com