Measuring method for rheological properties of special-shaped tubular drilling fluid

A measurement method and drilling fluid technology, applied in the direction of direct current flow characteristics measurement, etc., can solve the problems that cannot meet the needs of automatic measurement of drilling fluid rheology on site, and achieve the effects of automatic measurement, reduced sensitivity and reduced particle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

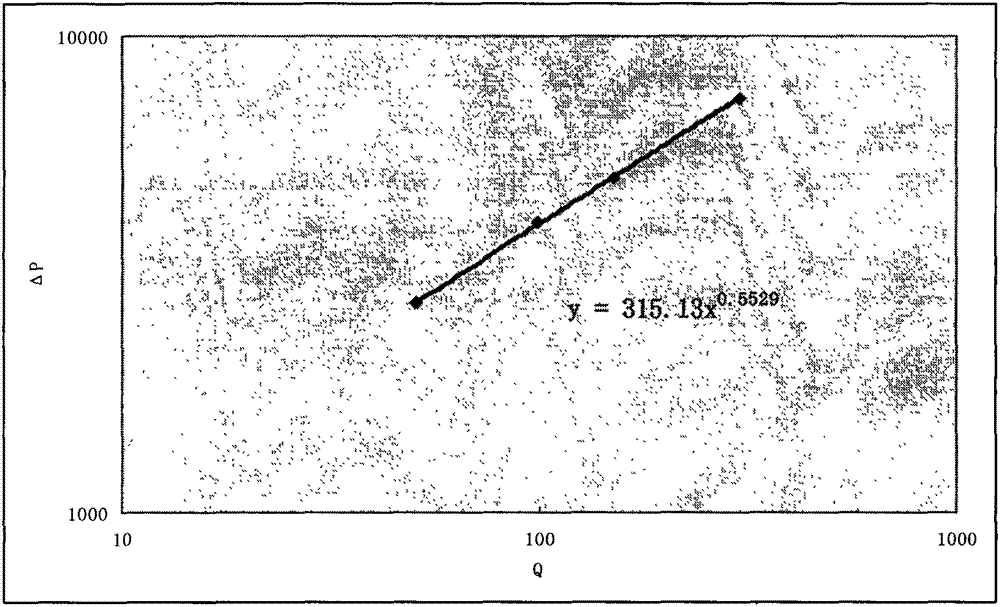

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and embodiments.

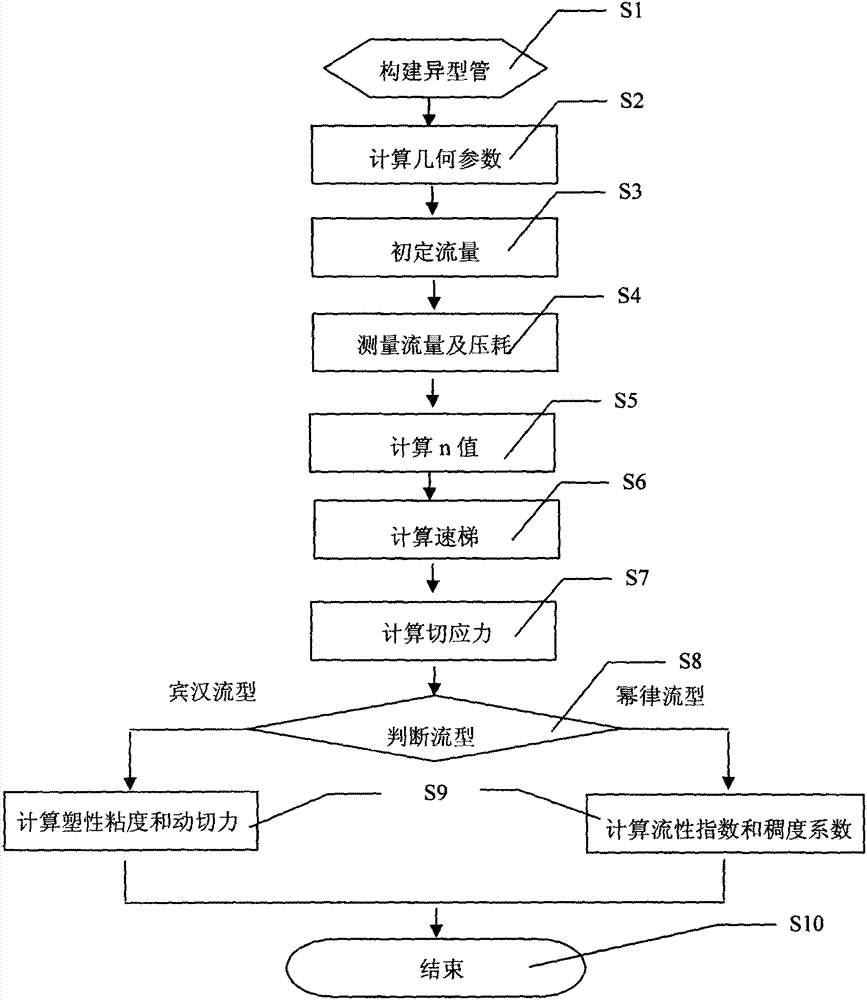

[0035] Reference to the overall implementation plan figure 1 with figure 2 .

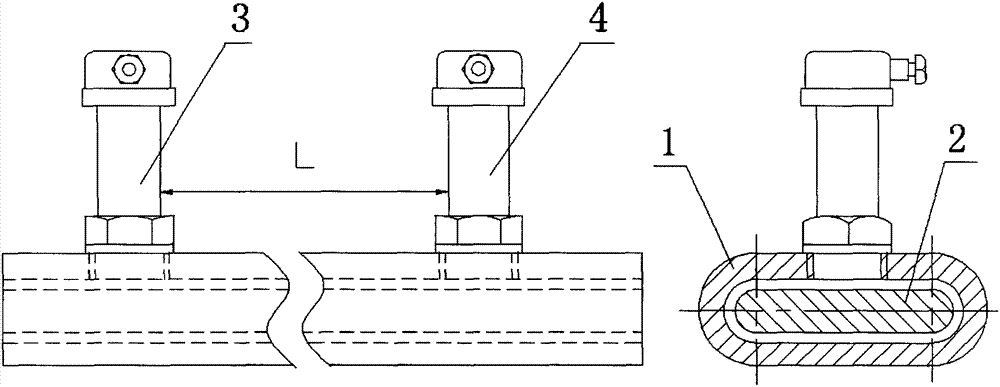

[0036] Step S1 to construct a special-shaped tube: the process starts at step S1, which constructs a structure composed of figure 2 The special-shaped tube shown is composed of a flat elliptic tube 1 and a flat elliptic cylinder. A flat elliptic annulus is formed between the flat elliptic tube and the flat elliptic cylinder; two flush membrane pressure sensors are installed on the flat elliptic tube wall, The distance between the flush membrane pressure sensor and the two ends of the flat oval tube is more than 10 times the hydraulic diameter.

[0037] Step S2: Measure the geometric parameters of the special-shaped tube: first measure the two semicircular radii r of the flat oval section formed by the inner wall of the flat oval tube 1 1 And the common tangent length b; secondly, determine the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com