Ferrite Cores and Transformers

A technology of ferrite iron and transformers, applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of increasing opportunities for use and increasing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~28

[0076] Each component raw material was weighed so that it might become the composition shown in Table 1, and it wet-mixed using the ball mill. After the raw material mixture is dried, it is calcined at a temperature of about 900° C. in air. The obtained calcined powder was charged into a ball mill, and wet pulverization was performed for 3 hours until the desired particle size was obtained.

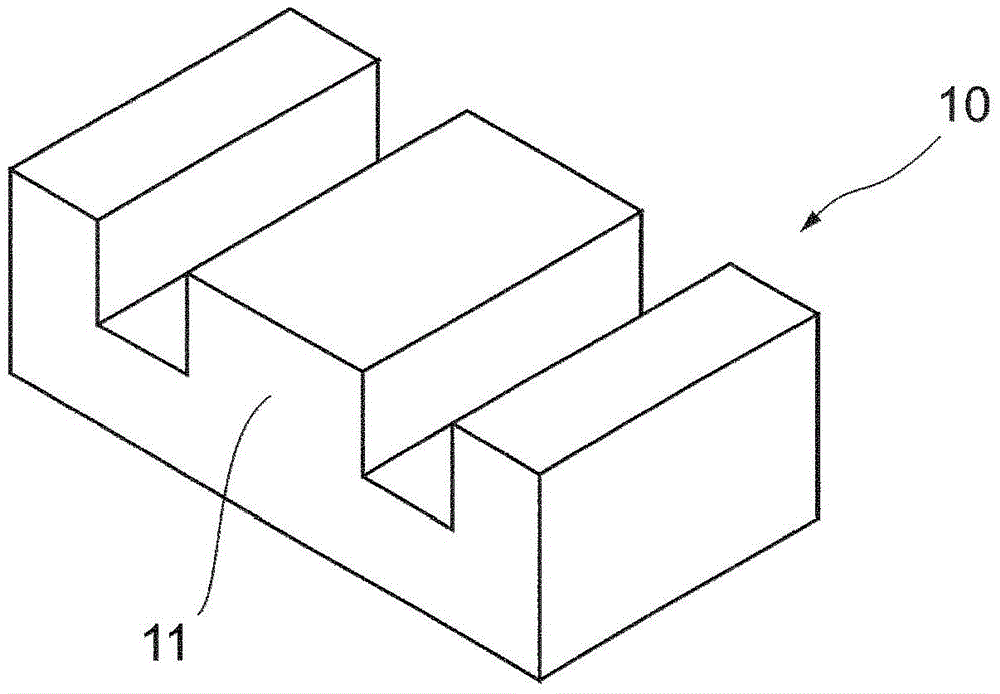

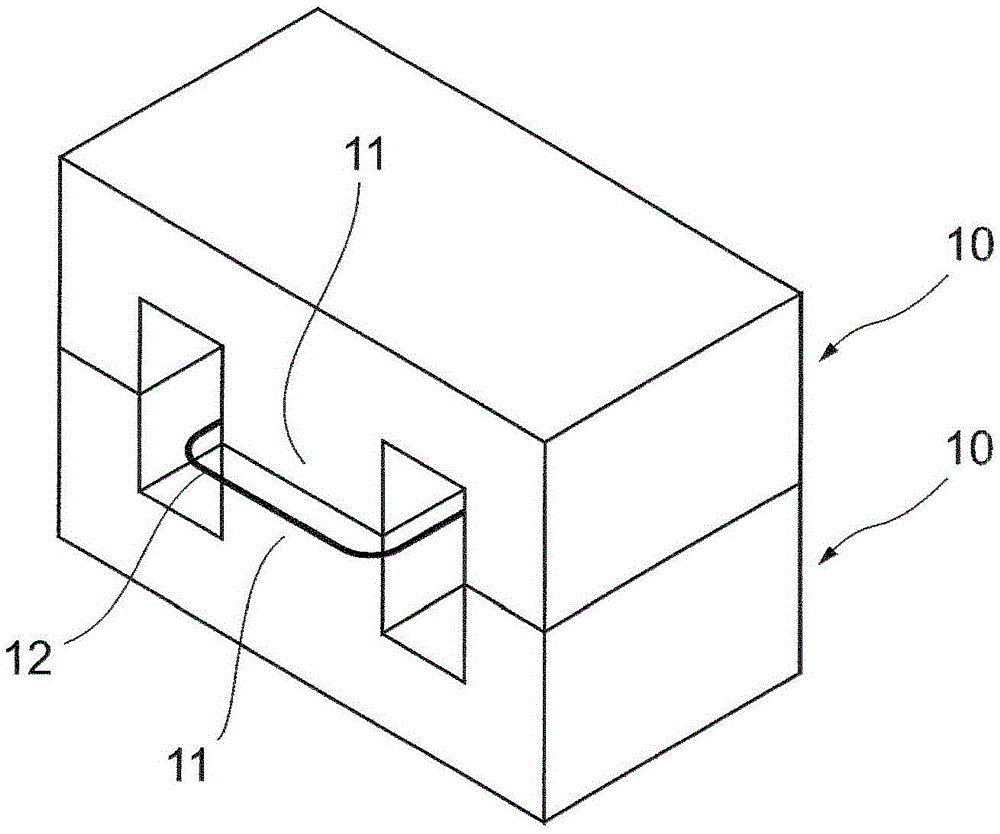

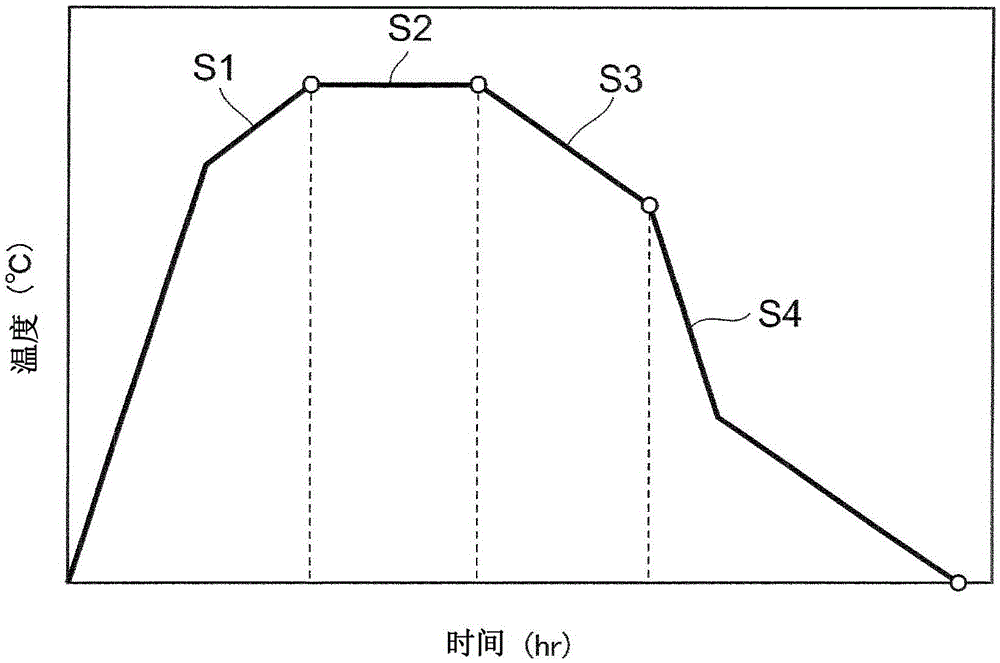

[0077] The pulverized powder thus obtained was dried, and after adding 0.8 parts by mass of polyvinyl alcohol to 100 parts by mass of the pulverized powder for granulation, the resulting mixture was press-molded at a pressure of about 150 MPa to obtain E Font shape. The molded body was mainly fired within the range of firing conditions shown below to obtain a plurality of E-shaped ferrite cores. In this main firing step, the holding temperature is 1250 to 1350°C, and the slow cooling end temperature is set to 900 to 1150°C. After completion of the slow cooling process S3, the atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com