A ground wire tension pole tower bridge crossing device for a power transmission line inspection robot

A line inspection robot, transmission line technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of obstacle crossing, inspection loss, increase the weight of the robot, etc., to achieve the effect of low cost, simple obstacle crossing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

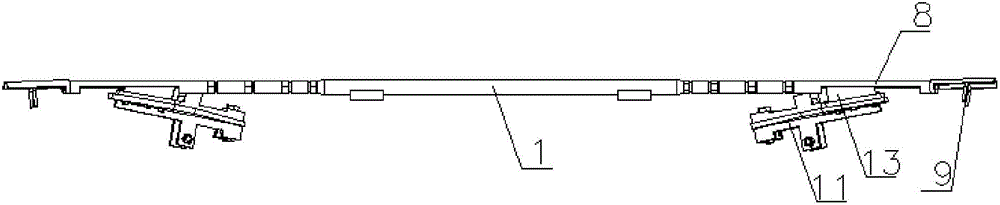

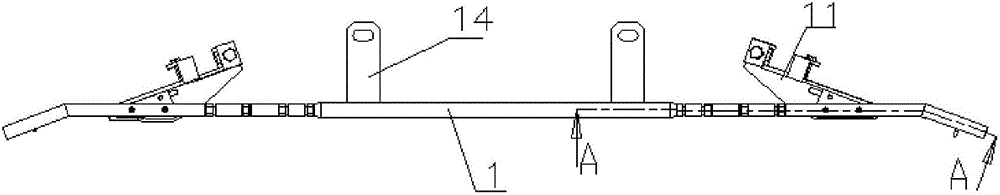

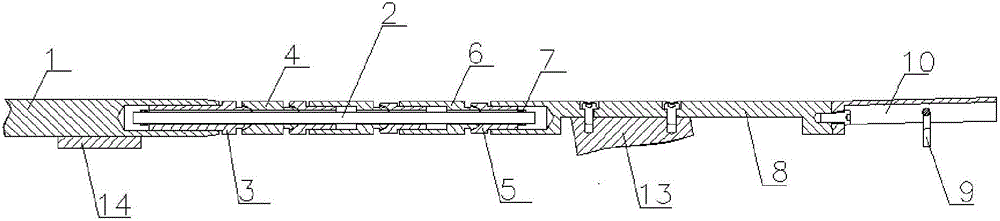

[0028] This device passes through the passage of the tension pole tower 17 as the machine inspection robot 18, and its main mechanism is a section of flexible bridge-passing mechanism. The flexible bridge-passing mechanism is connected to the cross-arm of the tension pole tower 17 through two support plates 14, and the end of the flexible bridge-passing mechanism is connected to the tension clamp through two sets of connecting and positioning components. When the inspection robot 18 traveling along the high-altitude transmission line travels along the transmission line 16 to the tension tower 17, the lock arm joint is released, and the shape of the two-wheel adaptive flexible bridge passing mechanism can roll over the bridge device and reach the tower 17. The other side has passed the tension tower 17. The line inspection robot traveling along the high-altitude transmission line can be selected from the patent No.: 201010195048.4, the name is: a robot for transmission line ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com