Conveyor device with powered endless pulling means for products from the tobacco processing industry

A technology of conveying device and traction mechanism, which is applied in the direction of tobacco, conveyor, transportation and packaging, etc. It can solve the problems of limitation, large conveying capacity, width limitation of continuous traction mechanism, etc., and achieve the effect of reducing sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

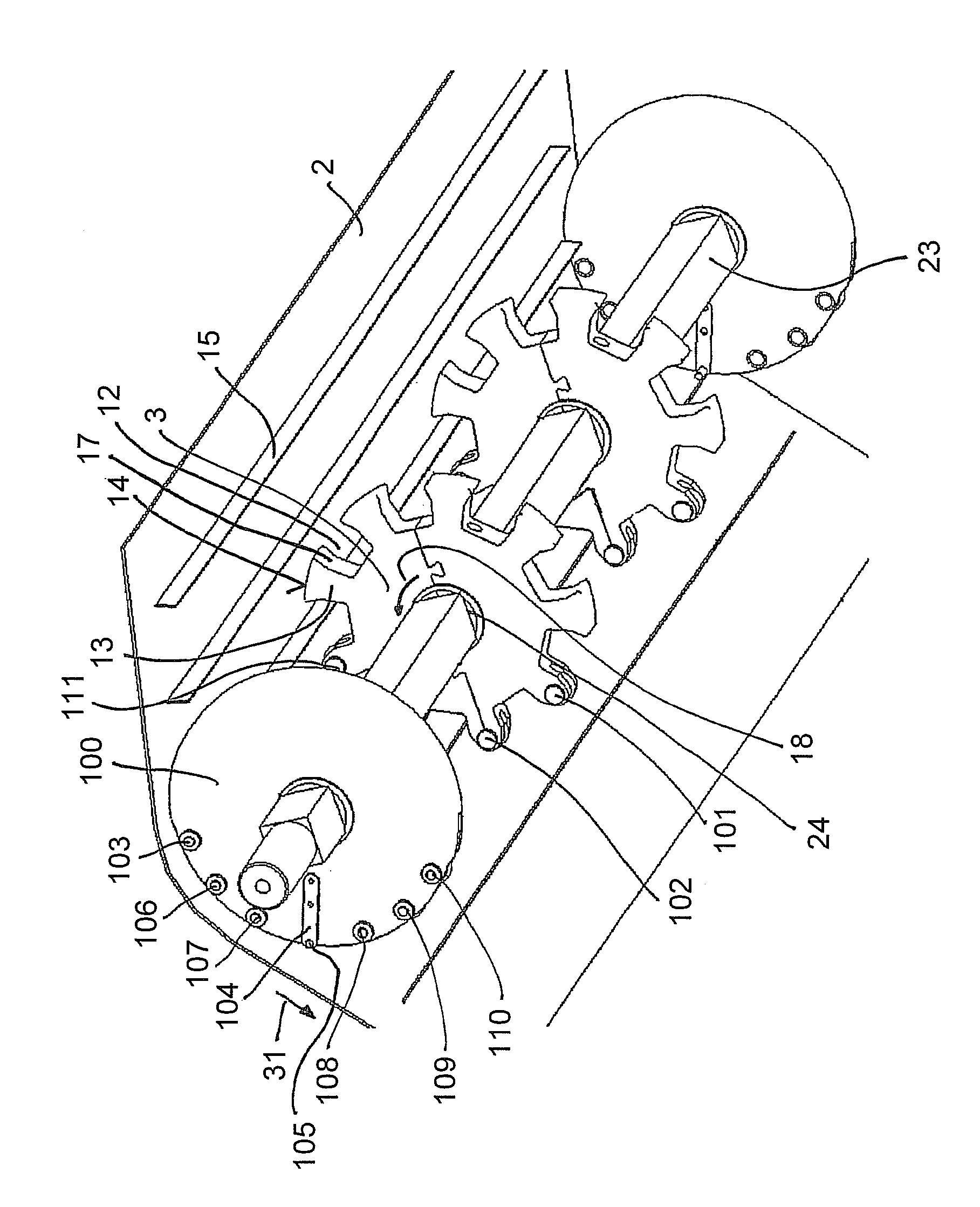

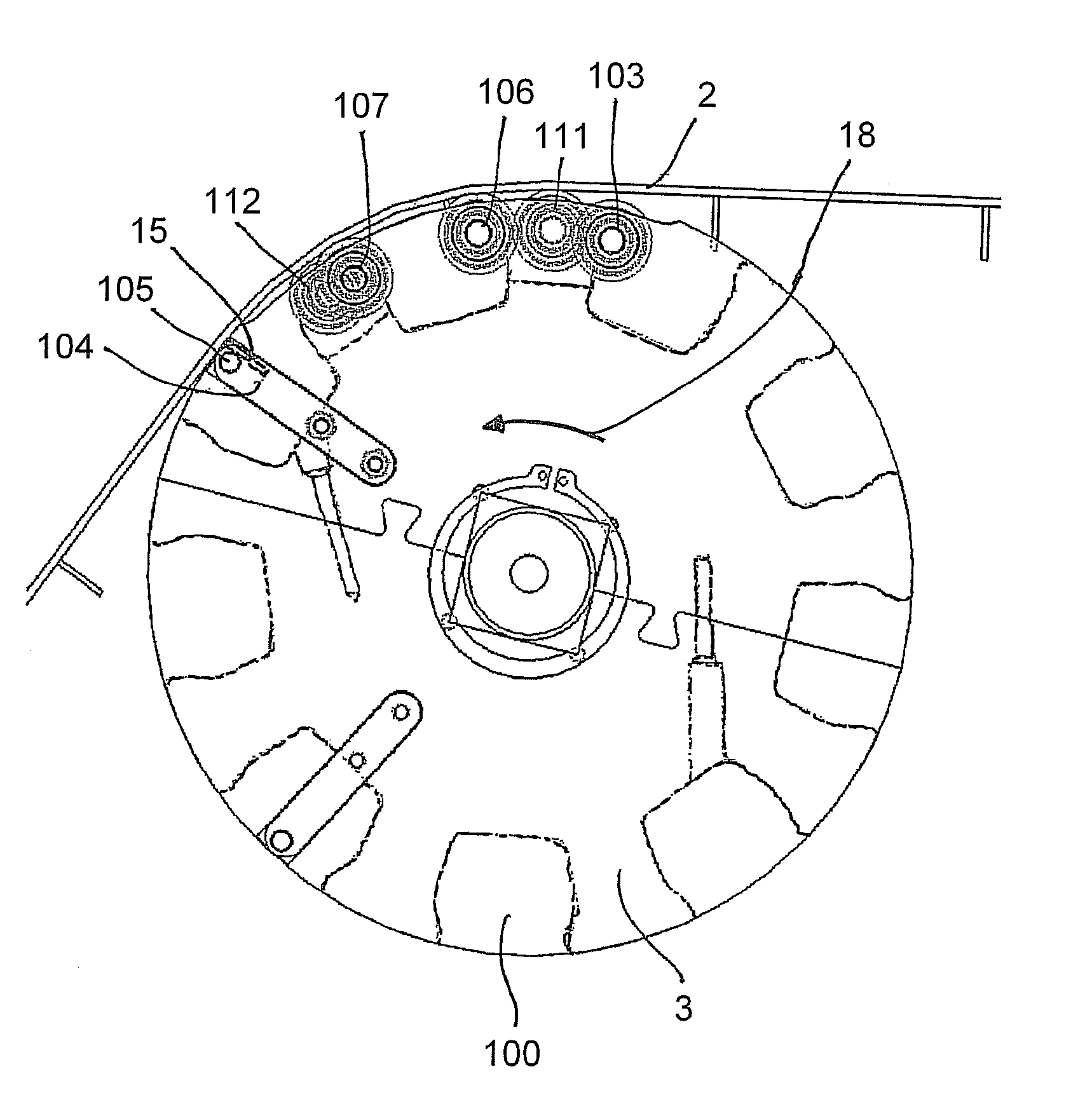

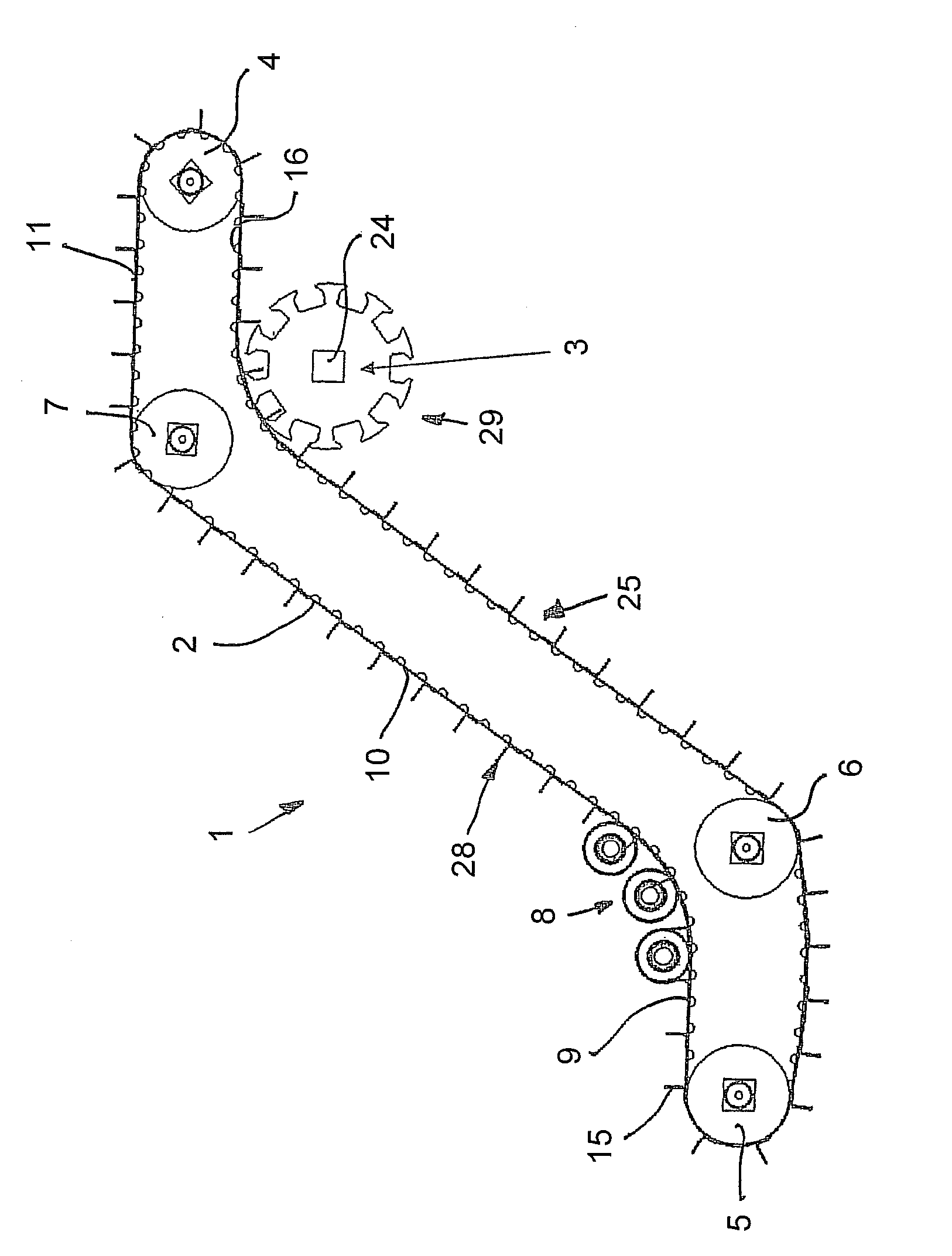

[0024] exist figure 1 A conveying device 1 with a continuous traction mechanism 2 constructed according to the invention can be seen in the figure. The continuous traction means 2 can be formed by a fabric belt, a fabric-reinforced elastomer belt or also of another material which is sufficiently flexible and at the same time has the necessary tensile strength for transmitting the tension force. The conveyor device 1 has a horizontal loading section 9 , a higher horizontal delivery section 11 and an inclined section 10 connecting the loading section and the delivery sections 9 and 11 to each other. In order to drive the continuous traction mechanism 2, the continuous traction mechanism is provided with protruding lugs 16 on its inner side, and the continuous traction mechanism 2 engages with correspondingly shaped lugs of the drive drum 4 in a form-fitting manner. In the gap, the drive roller can in turn be driven by a drive mechanism such as an electric motor. On the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com