Slider for zipper and zipper having same

A technology for zippers and sliders, applied in the field of zippers, which can solve problems such as peeling, harshness, scratches on the pull piece or slider body, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

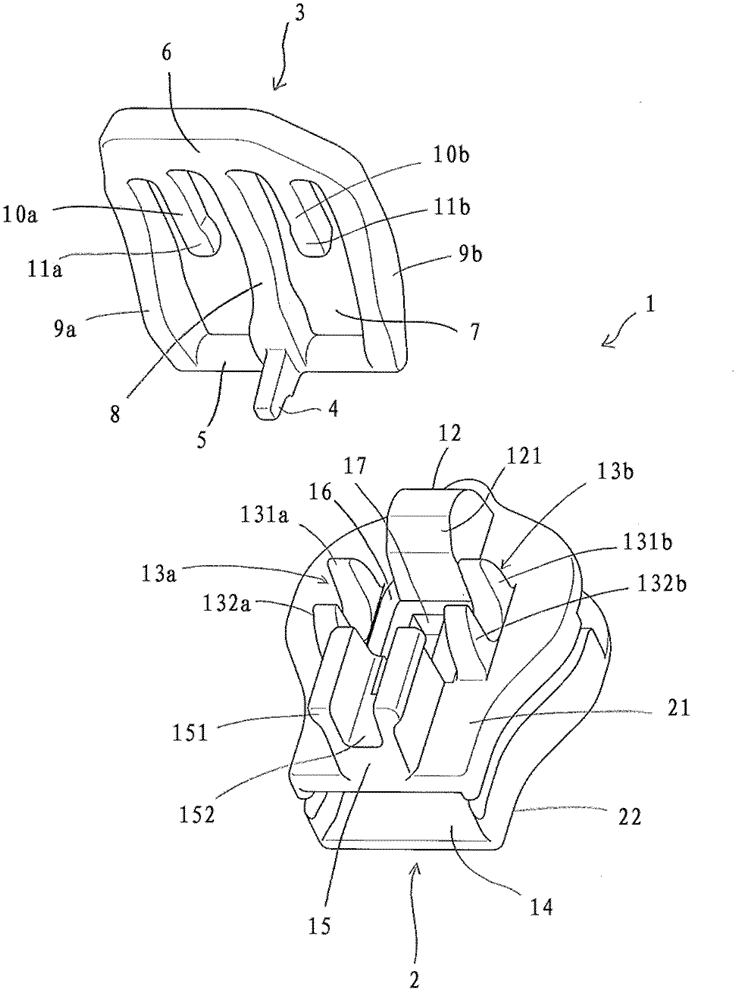

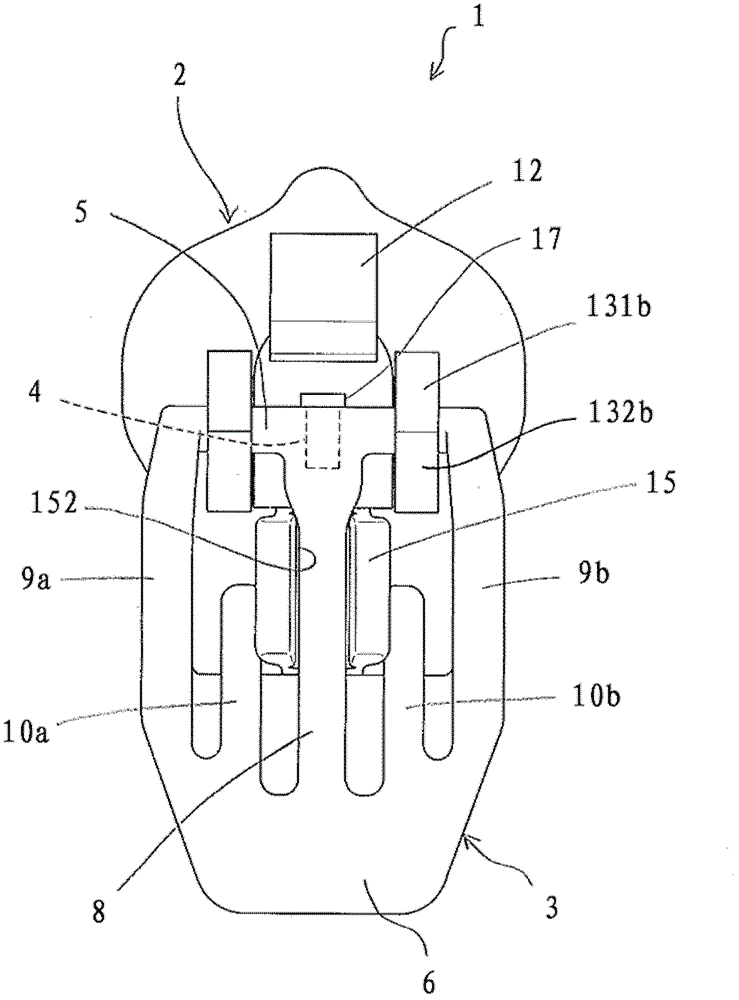

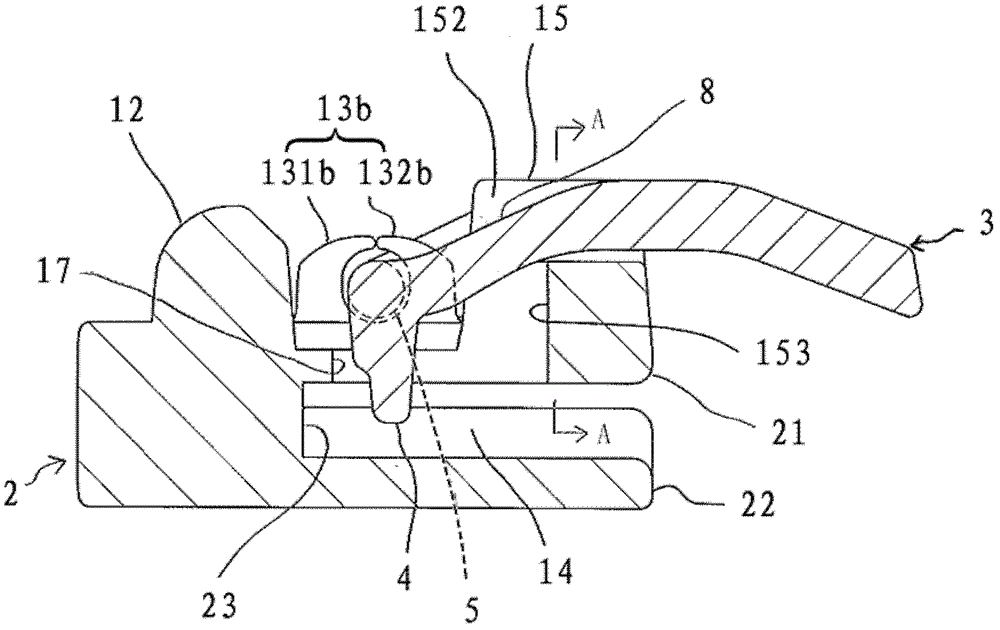

[0091] Figure 1 to Figure 5 It is a figure which shows the slider which concerns on 1st Embodiment of this invention. figure 1 It is an exploded perspective view of the slider according to the first embodiment of the present invention; figure 2 is a top view of the slider according to the first embodiment of the present invention, wherein the slider is in the first position; image 3 is a side sectional view of the slider according to the first embodiment of the present invention, wherein the slider is in the first position; Figure 4 for along image 3 A cross-sectional view of line A-A in ; Figure 5 It is a side sectional view of the slider which concerns on 1st Embodiment of this invention, wherein the handle is in a 2nd posture.

[0092] Such as figure 1 As shown, the slider 1 has a slider body 2 and a pull piece 3 , and the pull piece 3 can rotate between a first posture laid down on the slider body 2 and a second posture erected from the slider body 2 . In this ...

no. 2 approach

[0103] Figure 6 ~ Figure 7 It is a figure which shows the slider of 2nd Embodiment of this invention. Figure 6 It is a top view of the slider according to the second embodiment of the present invention, wherein the slider is in the first position; Figure 7 It is a side sectional view of the slider which concerns on the 2nd Embodiment of this invention, wherein the handle is in a 2nd posture. In addition, in the description of the present embodiment, the same reference numerals are attached to the same or corresponding parts as those of the first embodiment, and the description of the parts will be omitted.

[0104] Such as Figure 6 as well as Figure 7 As shown, compared with the first embodiment, in the second embodiment, the rod and the first groove for accommodating the rod are not formed. And, instead of being provided with one first column portion in the first embodiment, in the second embodiment, on the front side of the slider body 2, there are pullers along the...

no. 3 approach

[0108] Figure 8 ~ Figure 9 It is a figure which shows the slider which concerns on 3rd Embodiment of this invention. Figure 8 It is a top view of the slider according to the third embodiment of the present invention, wherein the slider is in the first position; Figure 9 It is a side sectional view of the slider which concerns on the 3rd Embodiment of this invention, wherein the handle is in a 2nd posture. In addition, in the description of the present embodiment, the same reference numerals are attached to the same or corresponding parts as those of the first embodiment, and the description of the parts will be omitted.

[0109] Such as Figure 8 as well as Figure 9 As shown, compared with the first embodiment, in this third embodiment, no recess is formed, but between the pair of left and right support parts 13a, 13b, the upper plate 21 of the slider body 2 is penetrated in the vertical direction. In such a manner, the hole portion 17 communicating with the element pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com