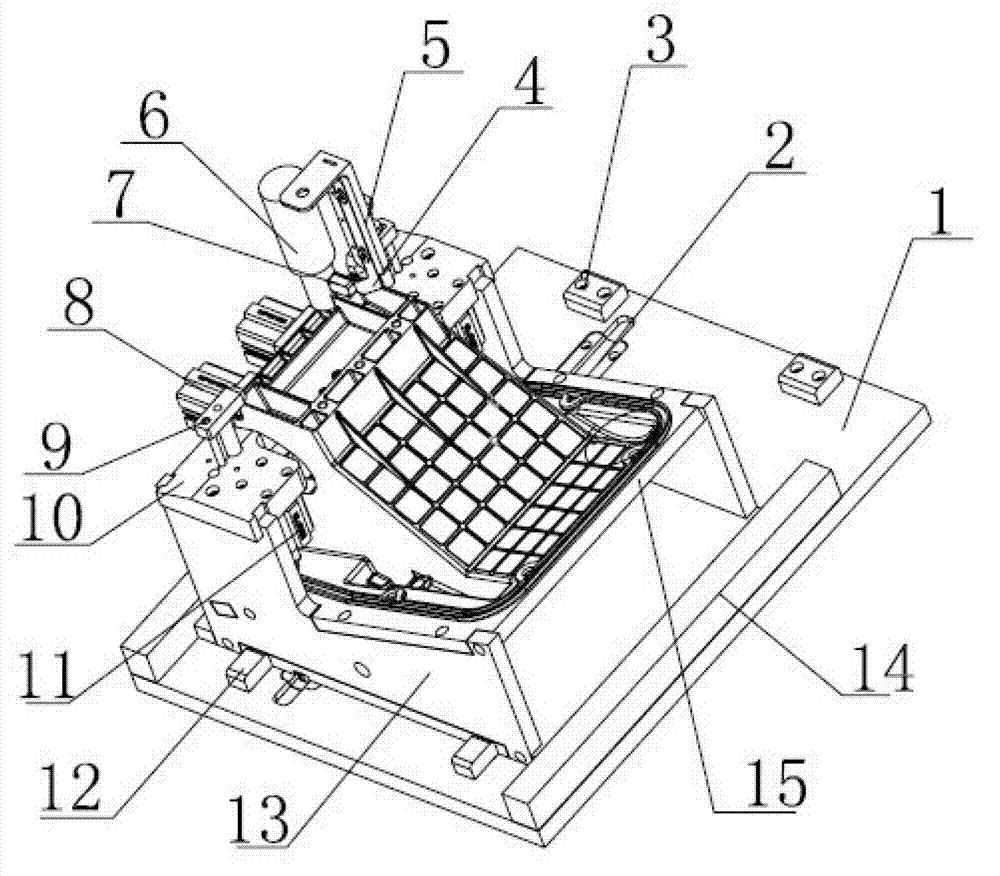

Assembly tool of self-tapping inserts of automobile pedal shell body

A technology of automobile pedals and assembly tooling, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as easy deviation, easy deformation, complex structure, etc., and achieve convenient processing position, convenient adjustment, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

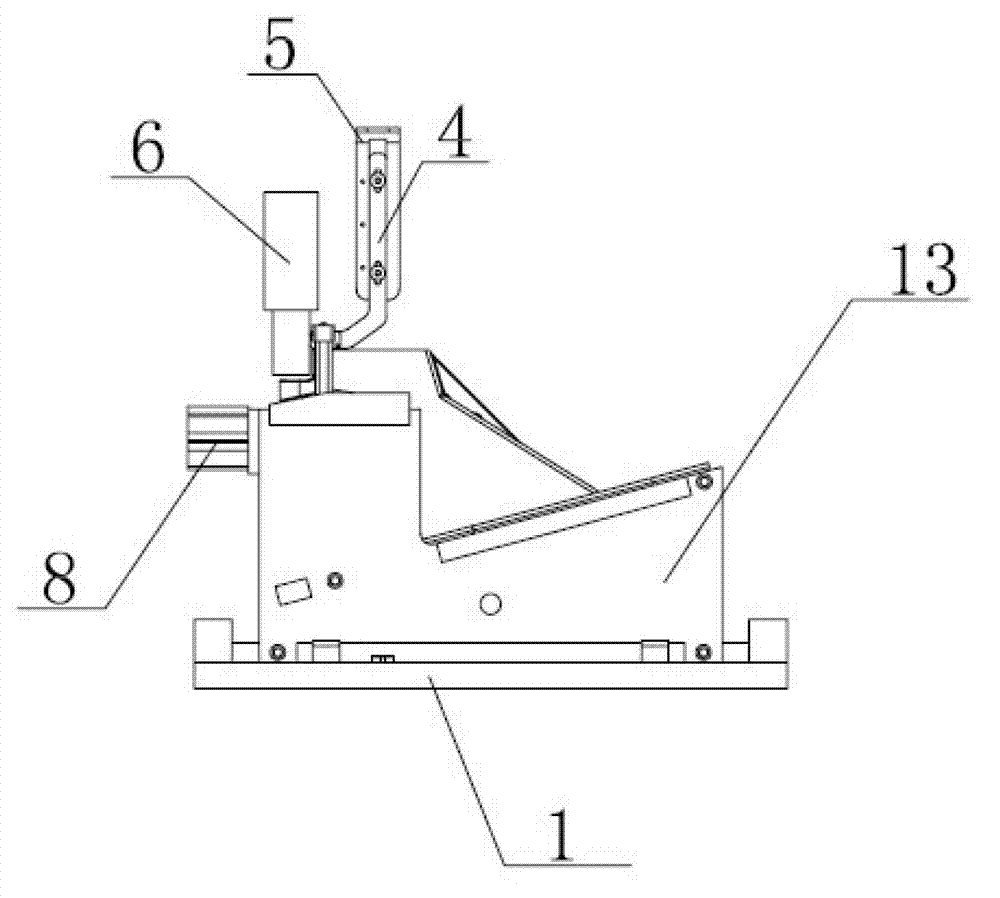

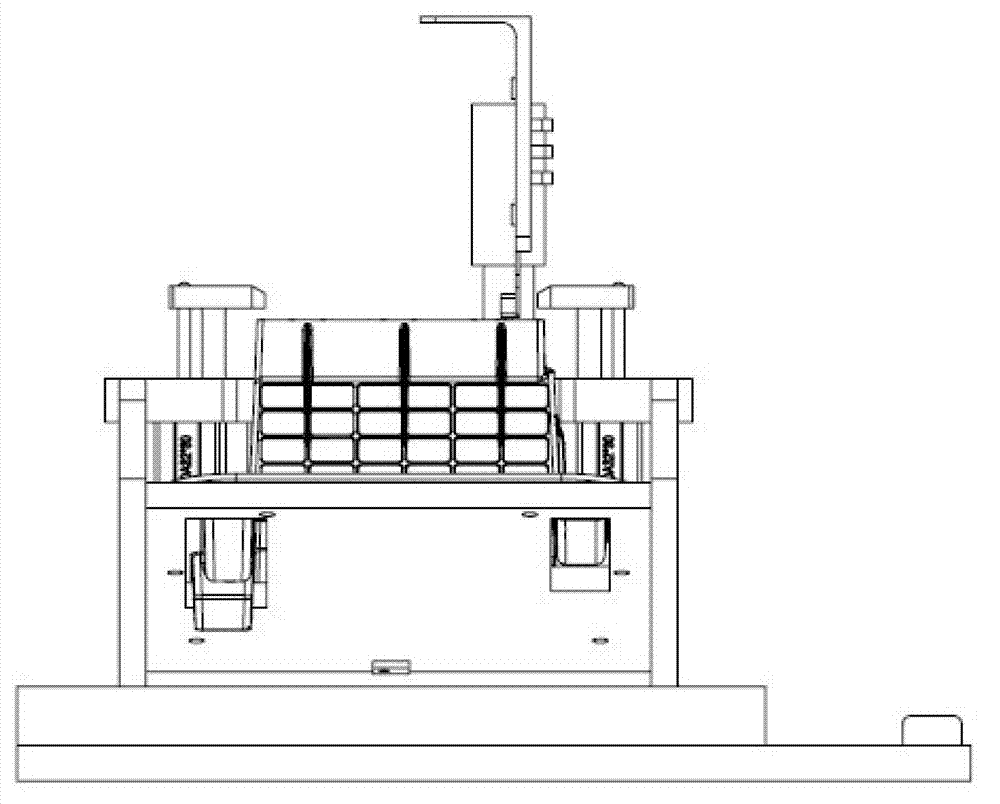

Method used

Image

Examples

Embodiment 1

[0027] A car pedal housing is placed on the installation base plate 15 and the installation top plate 10, the pressure plate cylinder 11 moves to drive the pressure plate 9 to press down the car pedal housing, and the floating support cylinder 8 moves upward to withstand the car pedal housing, and the car pedal After the shell is fixed, the self-tapping insert to be installed is fixed on the threaded shaft 64 at the lower end of the main shaft 61, the main shaft 61 starts to rotate, the tapping head assembly 6 and the connecting block 5 move downward together, and the self-tapping insert is installed on the specified When the sensor block 7 at the lower end of the connection block 5 hits the car pedal housing, the main shaft 61 stops rotating and starts to rotate in the reverse direction. When rotating in the reverse direction, the pin shaft 65 slides along the involute gap 631, Moving the nut 63 downward against the self-tapping insert prevents the main shaft threaded shaft 64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com