A beam with rolling and sliding rails

A beam and guide rail technology, applied in milling machine equipment, metal processing equipment, large fixed members, etc., can solve the problems of inefficient rough milling, poor machining accuracy, and difficult to guarantee machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

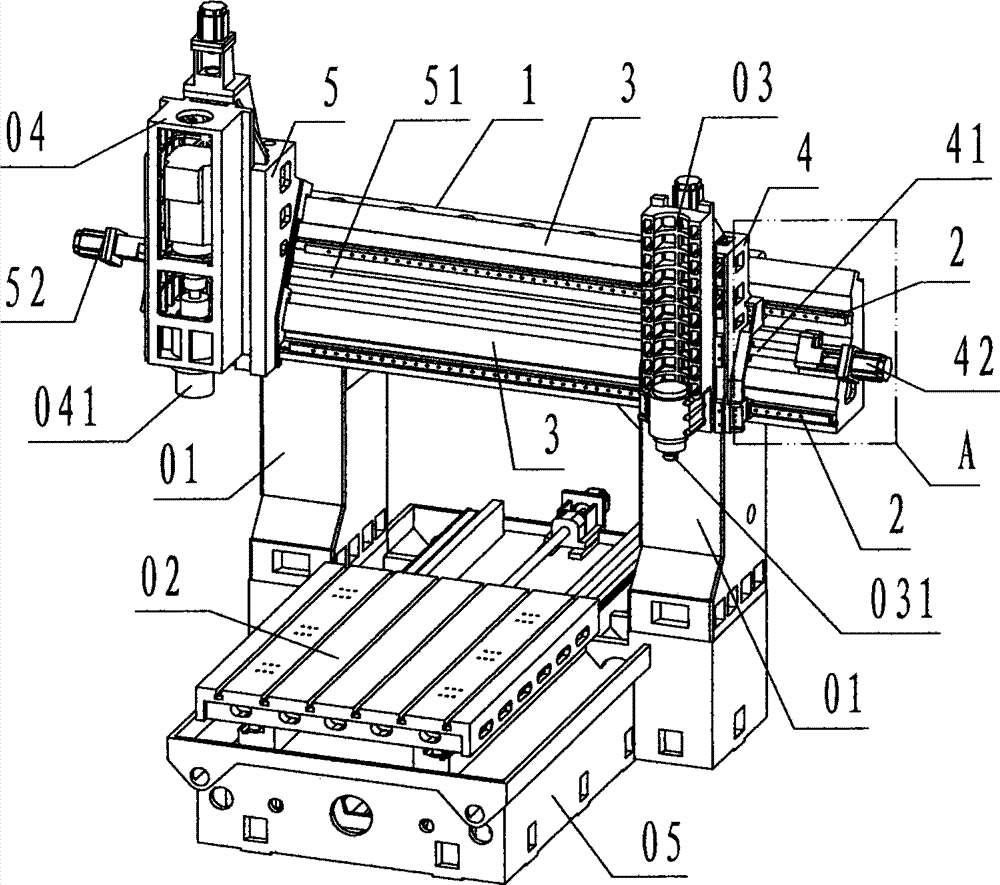

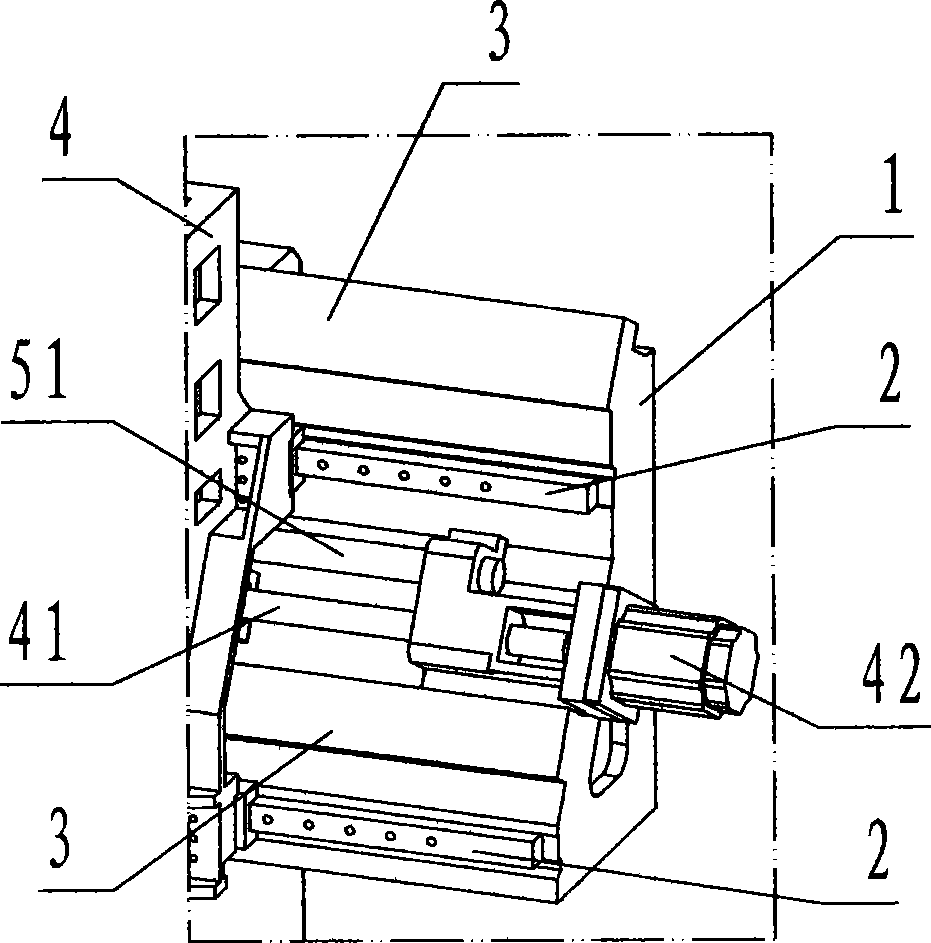

[0018] refer to Figure 1 ~ Figure 2 , a crossbeam provided with rolling and sliding guide rails according to the present invention includes a crossbeam 1, a rolling line rail 2 and a sliding hard rail 3, wherein: the crossbeam 1 is rectangular in main view, L-shaped in side view, The long block-shaped cast iron components horizontally fixed on the two columns 01 of the one-to-two CNC milling machine, and the middle and lower parts in front of the beam 1 are provided with two horizontal parallel grooves called line rail grooves;

[0019] The sliding hard rails 3 are two horizontally parallel rails with an inverted V-shaped cross-section arranged on the top of the crossbeam 1 and the front middle; The front left part of 1; the heavy-duty lateral motion device 5 is a device for undertaking the heavy-duty rough milling task for controlled lateral motion consisting of a heavy-duty vertical motion device 04 and a heavy-duty spindle motor 041; the heavy-duty lateral motion device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com