A CNC four-axis device

The technology of a shaft device and a rotating shaft is applied in the field of numerical control rotating shaft clamping device, which can solve the problems of low production efficiency, high processing cost, and high production cost of four-axis machining parts, and achieve the effect of improving efficiency and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

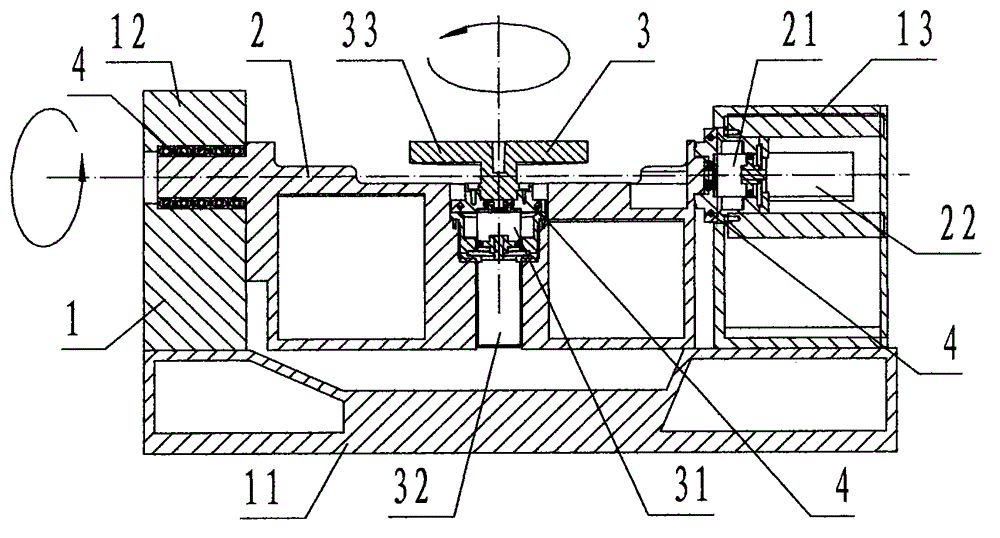

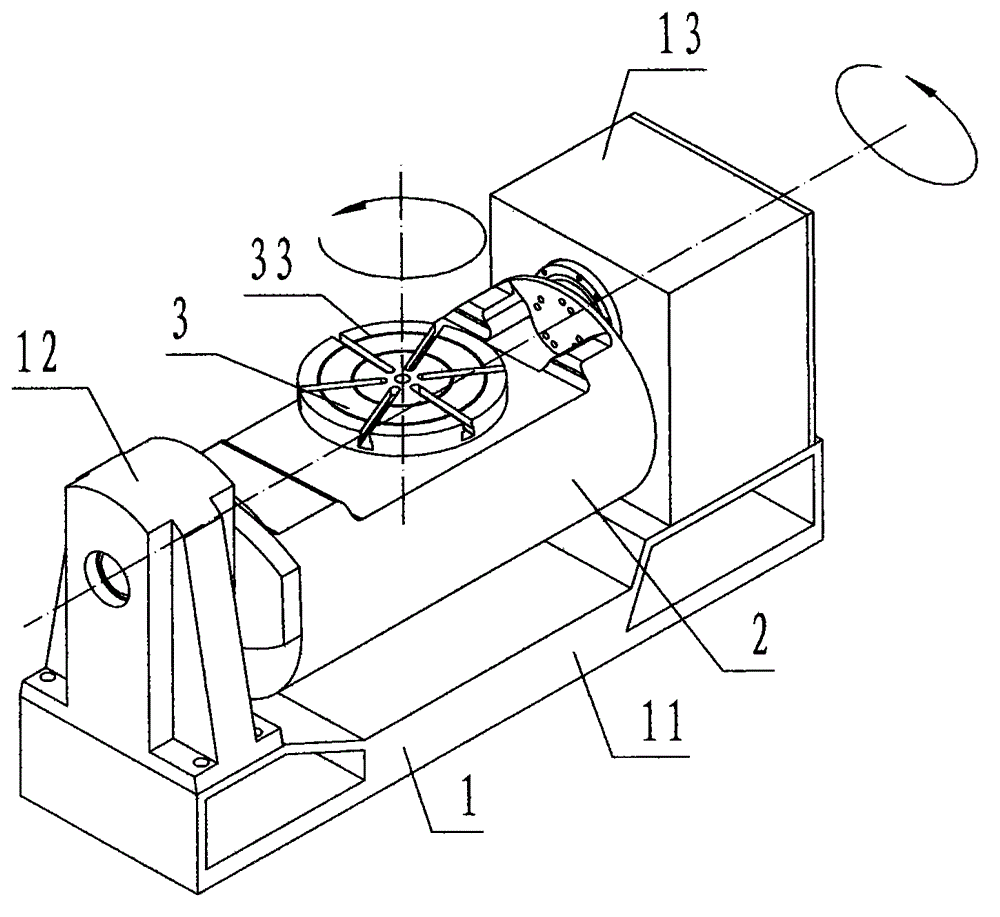

[0017] refer to figure 1 , figure 2 , a numerically controlled four-axis device of the present invention, comprising a base 1, a horizontal rotating shaft 2, and a longitudinal rotating shaft 3, wherein: the base 1 is a concave steel member, and the bottom of the base 1 is a rectangular block The base 11, the left end of the base 11 is fixed with a vertically upwardly protruding support called a bearing frame 12, and the right end of the base 11 is fixed with a vertically upwardly protruding rectangular hollow closed box-shaped support called a support box 13, The upper center of the bearing frame 12 is provided with a circular through hole that runs through the left and right horizontal directions and is called the left bearing hole. The circular through hole is called the right bearing hole, the axes of the left bearing hole and the right bearing hole are correspondingly coincident, and the bearing 4 is arranged in the left bearing hole and the right bearing hole;

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com