A vertical CNC drilling and milling machine tool

A drilling and milling machine tool and vertical technology, which is applied to metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems of high labor cost, low drilling, tapping and milling processing efficiency and high cost of CNC machining centers. Achieving the effect of low cost, improved efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

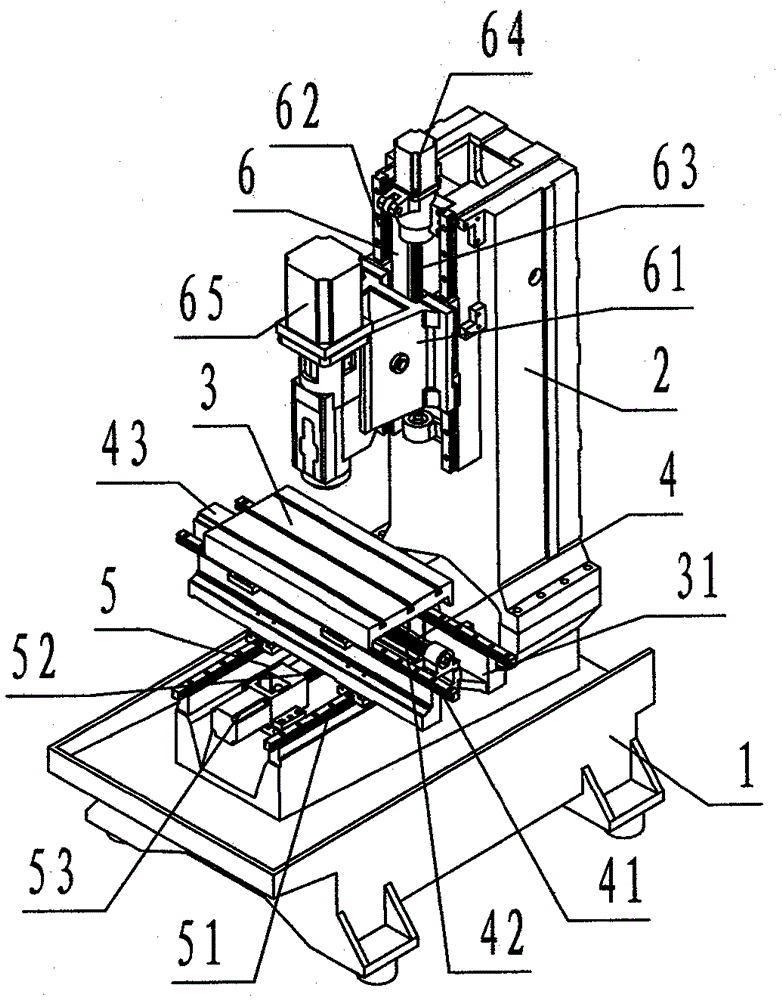

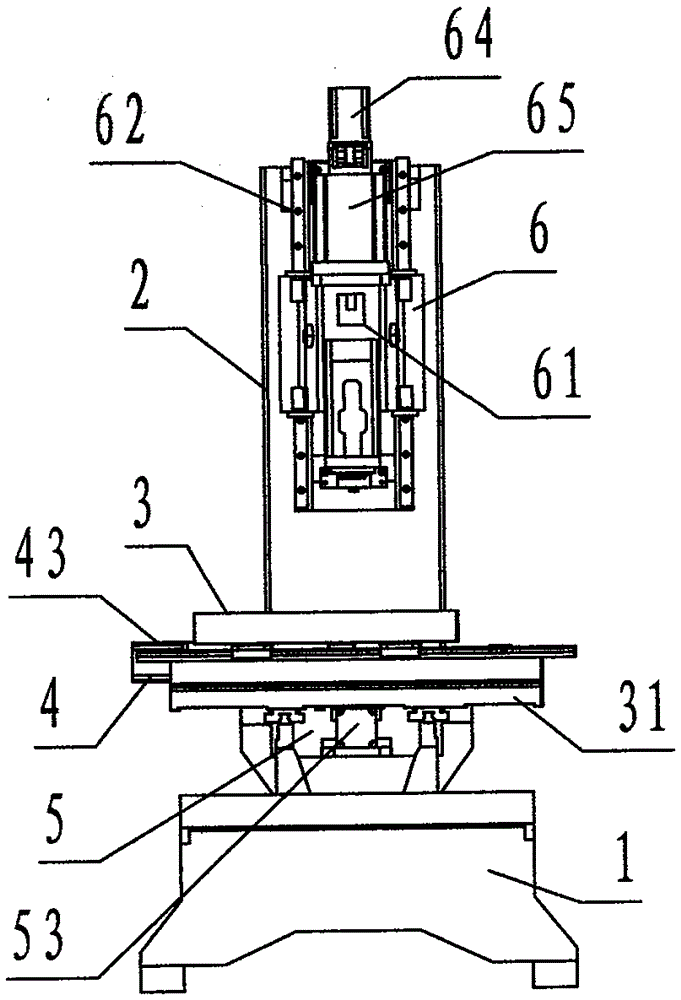

[0026] refer to figure 1 , figure 2 , a vertical CNC drilling and milling machine tool of the present invention, comprising a bed 1, a column 2, a workbench 3, an orthogonal carriage 31, an X slide pair 4, a Y slide pair 5, and a Z slide pair 6, wherein : the bed 1 is a rectangular platform-shaped hollow cast iron member, the bottom four corners of the bed 1 are provided with bed feet; , along the two sides of the center line of the long side, there are two groove-shaped bosses protruding upwards and in the front and rear direction symmetrically, which are called Y-axis connecting seats, and the hollow inner wall of the bed 1 is provided with criss-cross reinforcement ribs;

[0027] The column 2 is a rectangular columnar hollow cast iron component, and the upper middle part of the front of the column 2 is provided with two groove-shaped bosses protruding forward, up and down and parallel to each other, which are called Z-axis connecting seats;

[0028] The workbench 3 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com