Grey-tile mud block transection equipment for manufacturing grey tiles

A green tile and cross-cutting technology, which is applied in the field of green tile raw material processing equipment, can solve the problems of difficulty in mastering the flatness of the cutting process, sticking of clay cubes, and difficult processing, etc., and achieve the effects of improving efficiency, not easy to break, and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

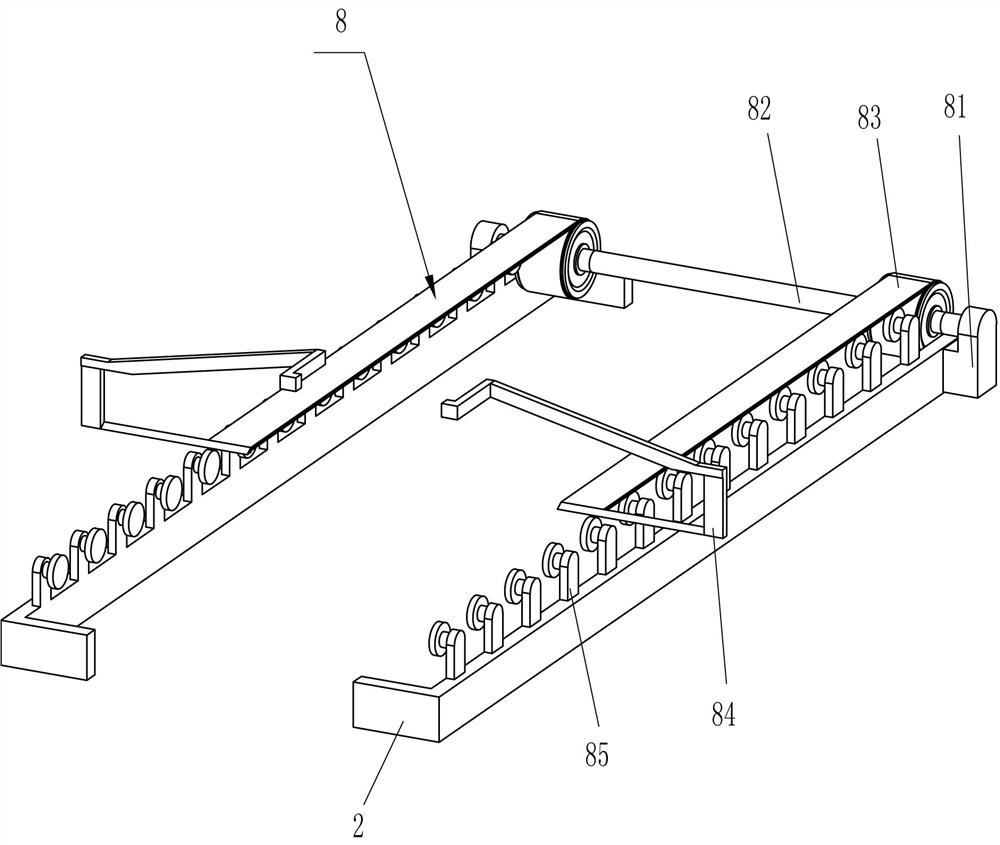

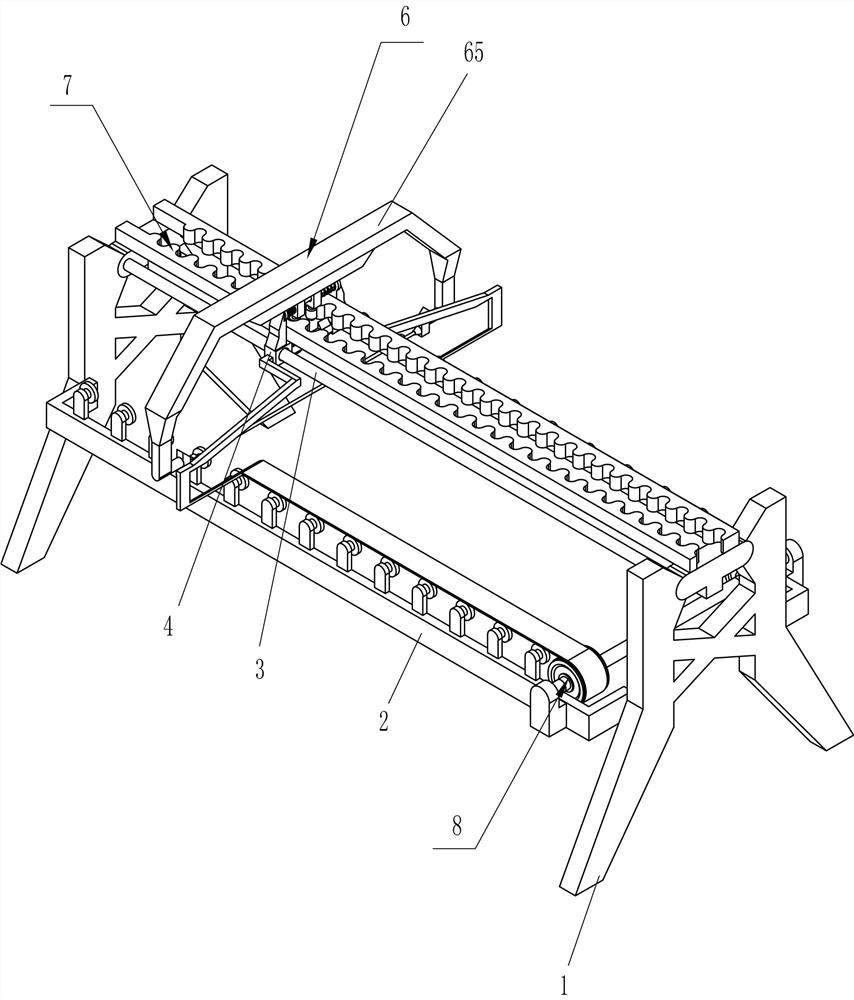

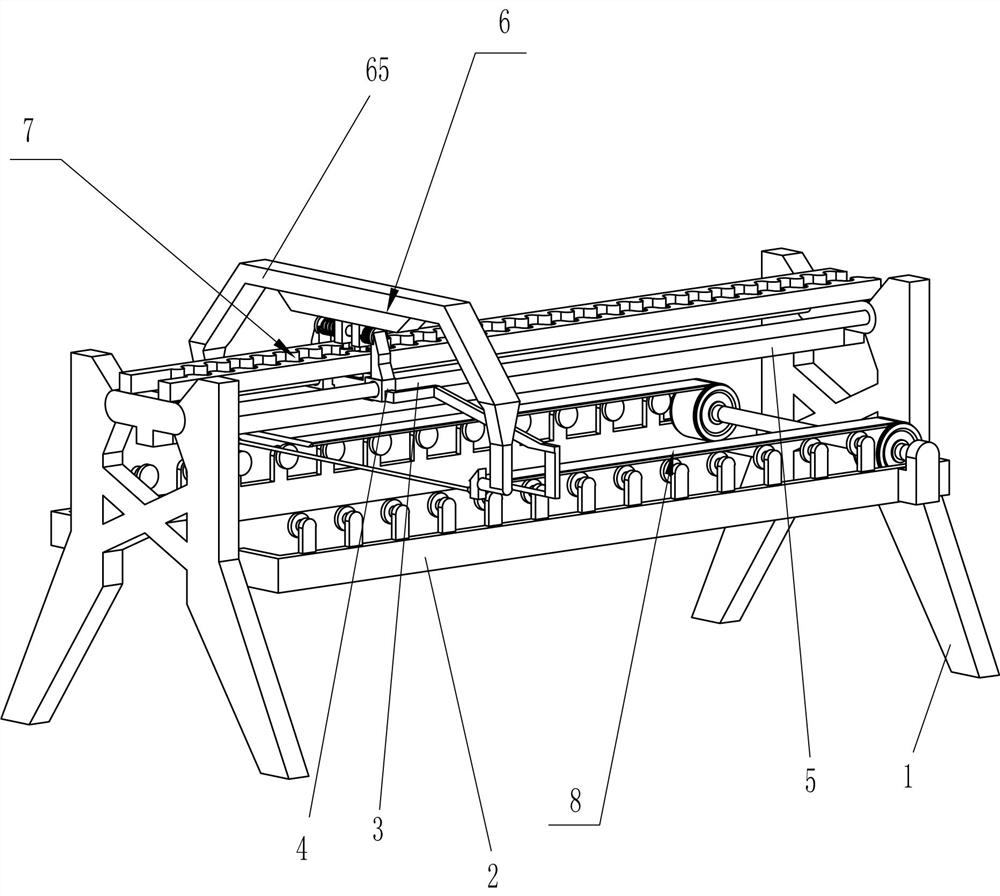

[0022] A kind of green tile mud cross-cutting equipment for blue tile production, such as Figure 1-3 As shown, it includes a support frame 1, a connecting frame 2, a first guide rail 3, a first guide sleeve 4, an electric slide rail 5, and a cutting device 6, specifically:

[0023] The number of support frames 1 is two groups, the two groups of support frames 1 are connected with connecting frames 2 between the front and rear sides, the upper sides of the support frames 1 are connected with the first guide rail 3, and the first guide rail 3 is slidingly connected with the first guide rail 3. The upper side between the guide sleeve 4 and the support frame 1 is connected with an electric slide rail 5 , the moving part of the electric slide rail 5 is connected with the first guide sleeve 4 , and the first guide sleeve 4 is provided with a cutting device 6 .

[0024] When the above-mentioned embodiment is in operation, when the blue tile mud square needs to be cut horizontally, t...

Embodiment 2

[0026] On the basis of Example 1, such as Figure 3-6 As shown, the cutting device 6 includes a fixed frame 61, a second guide rail 62, a second guide sleeve 63, an elastic member 64, a moving frame 65 and a cutting rope 66, specifically:

[0027] The upper side of the first guide sleeve 4 is connected with a fixed frame 61, the upper side of the fixed frame 61 is connected with a second guide rail 62, and the second guide rail 62 is slidably connected with two second guide sleeves 63, and the second guide sleeve 63 is connected to the upper side of the first guide sleeve 4. An elastic member 64 is connected between the second guide rails 62 , a moving frame 65 is connected between the upper sides of the second guide sleeves 63 , and a cutting rope 66 is connected between the lower sides of the moving frames 65 .

[0028] When the above embodiment is in operation, when the first guide sleeve 4 moves to the left, the first guide sleeve 4 will drive the fixing frame 61 to move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com