A self-locking bottle stopper that can release steam gas pressure

A gas pressure and self-locking technology, which is applied in sealing plugs, liquid handling, bottle filling, etc., can solve problems such as lack of heat preservation, bottle liner bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

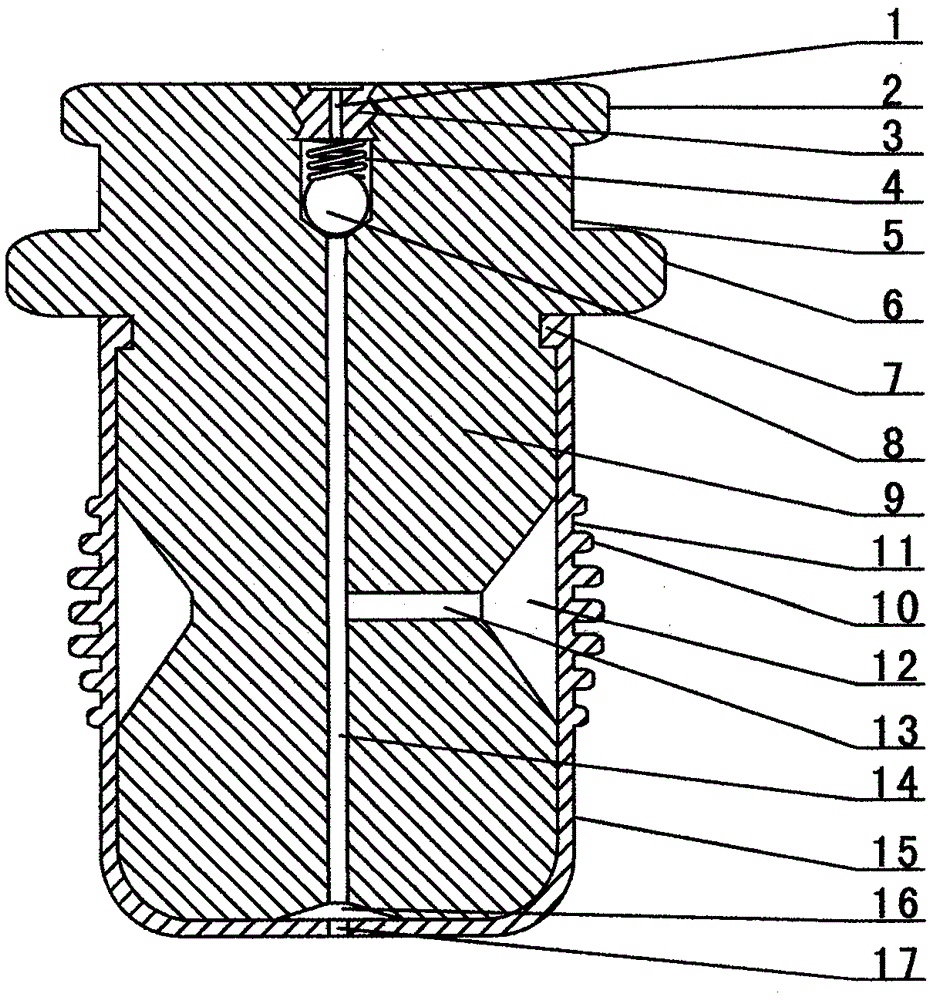

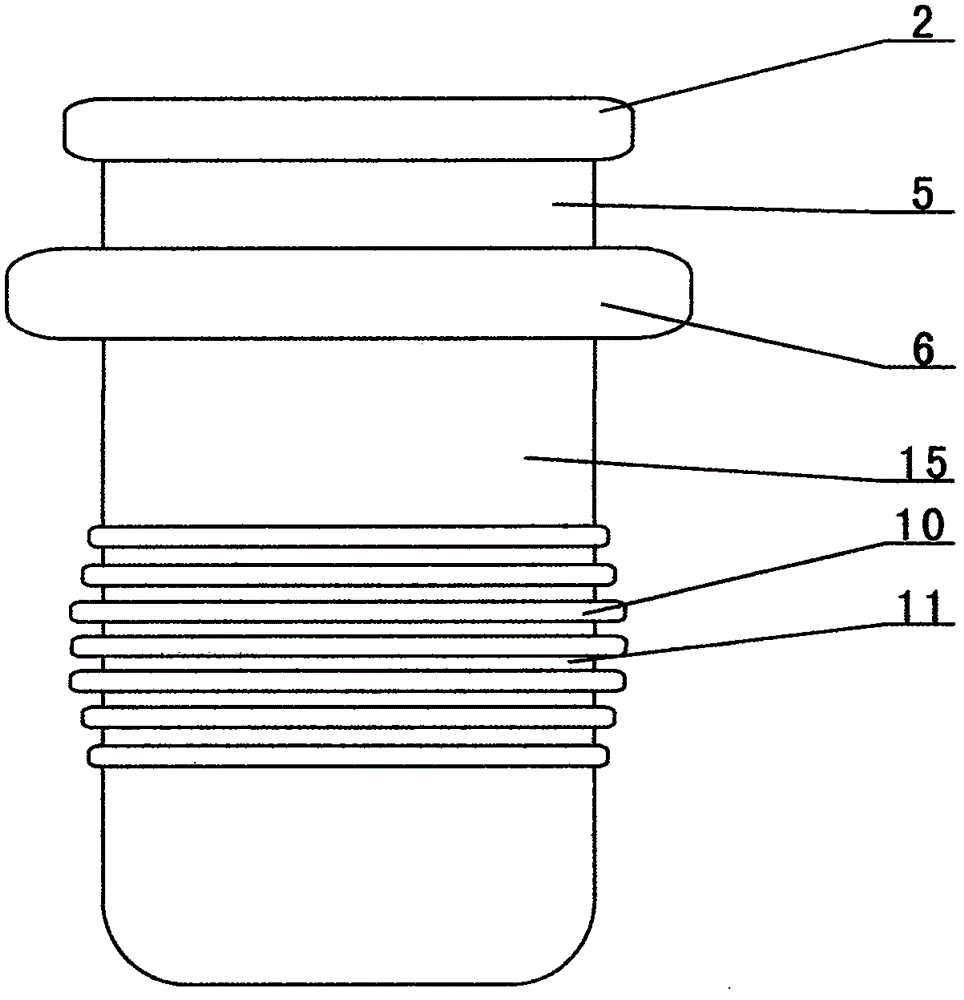

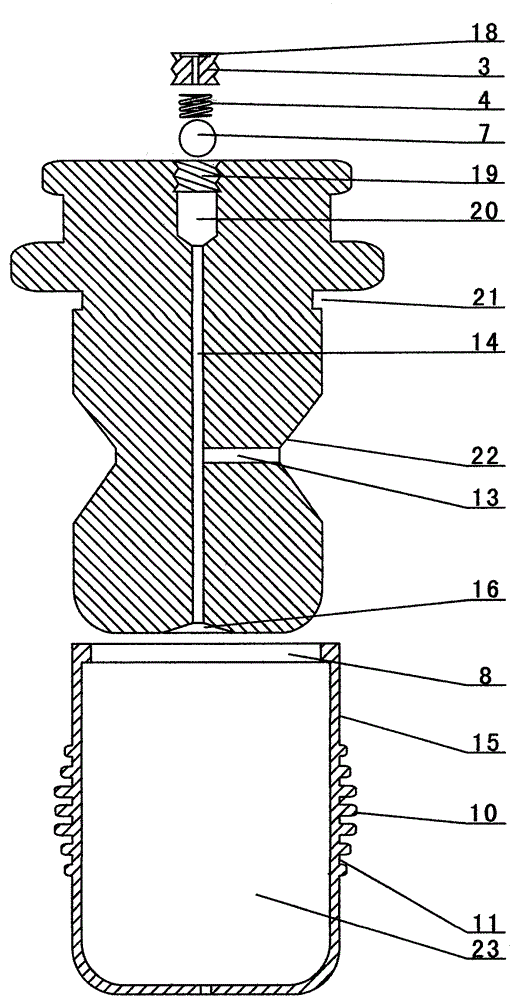

[0017] exist figure 1 , 2 3. The self-locking bottle stopper capable of releasing steam gas pressure, comprising a rubber cylinder 15, an inner cylinder 9, a sphere 7, a spring 4 and an external threaded cylinder 3, and an inner ring 8 is provided on the inner surface of the upper opening of the rubber cylinder 15, The middle part of the outer edge surface of the rubber cylinder 15 is provided with a plurality of surrounding ring-shaped raised strips 10, and the middle part of the lower end of the rubber cylinder 15 is provided with a hole 17; A cylindrical handle 5 is provided, an annular protrusion 2 is provided on the outer edge surface of the upper end of the cylindrical handle 5, and an annular groove 21 is provided near the retaining rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com