Barrel tilting device

A pouring device, supporting arm technology, applied in packaging, emptying containers, bottle filling, etc., can solve the problem of wasting time and human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

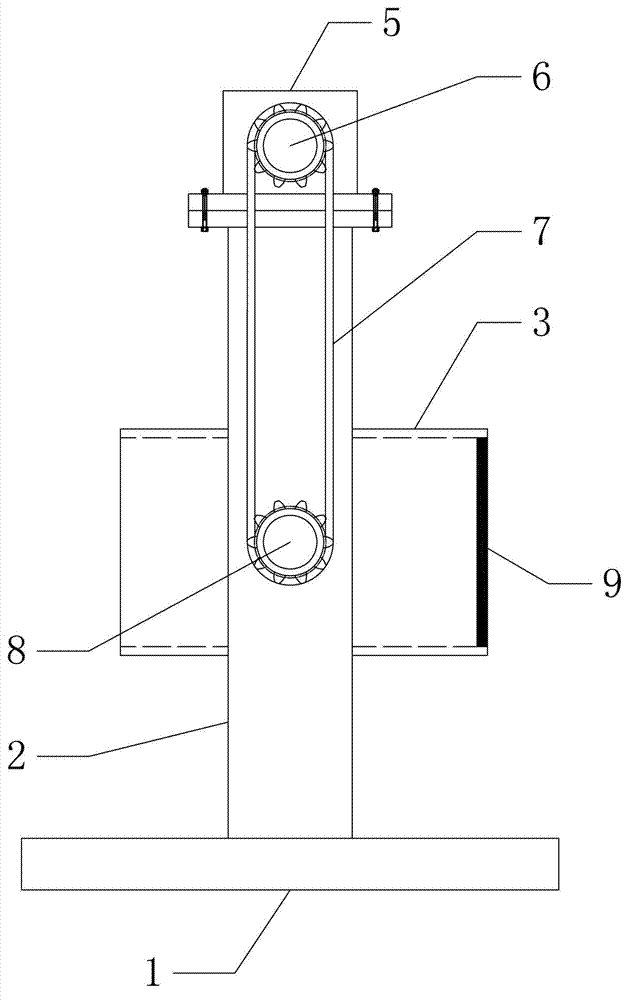

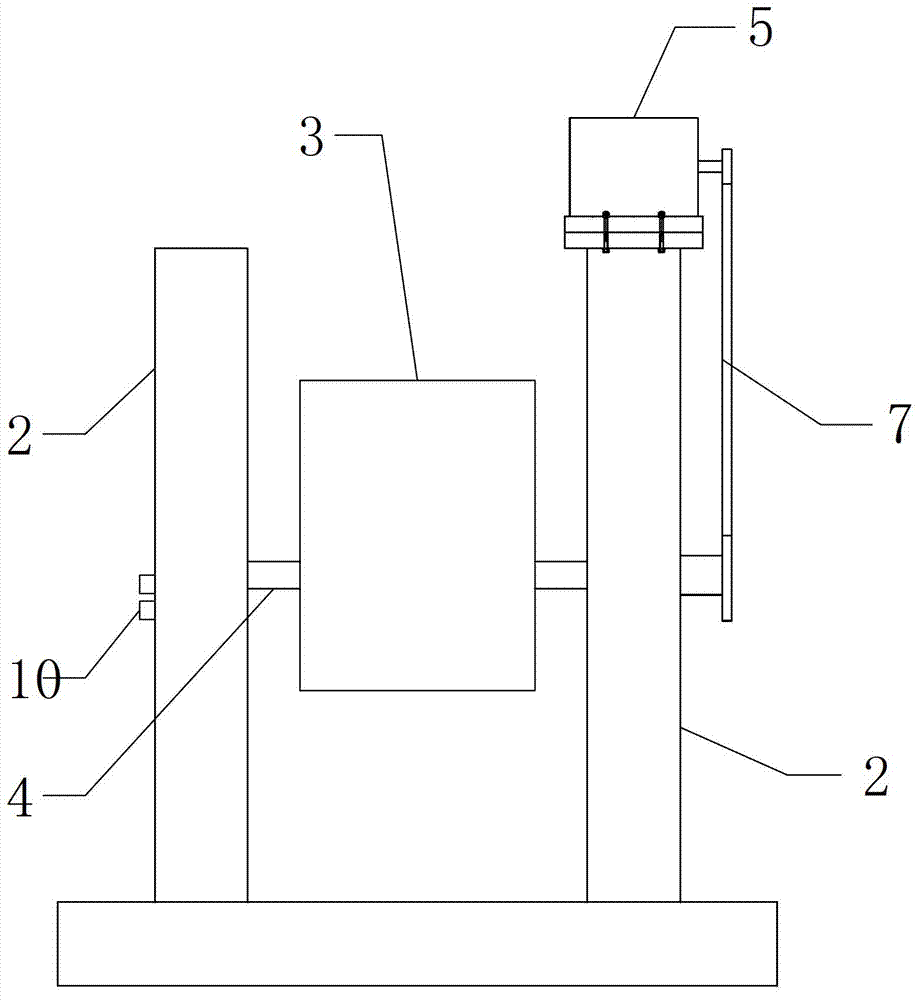

[0010] Such as figure 1 and figure 2 The bucket dumping device shown includes: a base 1, a support arm 2, a dump bucket 3, a rotating shaft 4 and a drive motor 5; the base 1 is fixed on the ground; the support arm 2 is fixed on the upper end surface of the base 1; the dump bucket 3 Connected with the support arm 2 through the rotating shaft 4; the rotating sprocket 8 is fixed at the 3 ends of the non-fixed dumping bucket of the rotating shaft 5; the driving motor 5 is fixed on the upper end of the supporting arm 2 through bolts; the output shaft end of the driving motor 5 is fixed with a driving sprocket 6 The driving sprocket 6 and the rotating sprocket 8 are connected by a chain 7; the electromagnet layer 9 is fixed at the bottom of the dumping bucket 3, and the support arm 2 is provided with a switch button 10 for controlling the electromagnet layer 9 to be energized;

[0011] The user of the present invention who has adopted the above technical solution first places the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com