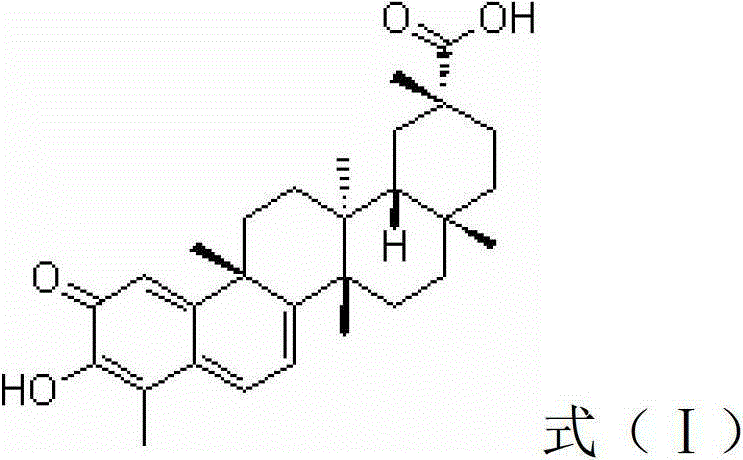

A method for extracting tripterine

A technology for triptolide and extract is applied in the field of extracting triptolide, which can solve the problems of complex process, low yield, small preparation amount and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment is used to illustrate the method for extracting tripterine provided by the present invention.

[0043] Get 218 grams of the dry root bark of S. chinensis of the genus S. chinensis and pulverize it. Each time, use 1200 mL of methanol to reflux extract for 1 hour, filter, and extract three times in total. The extraction products obtained each time are mixed to obtain 3390 mL of Tripterygium wilfordii. The content of element is the alcohol extract of 0.0625% by weight. The methanol in the ethanol extract is removed to obtain an extract. The extract was suspended in 300 mL of water and then extracted with 250 mL of chloroform each time for a total of 3 extractions. After the chloroform extract was concentrated to about 8mL (the content of tripterine in it was 1.98g), the sample was mixed with 20g of diatomaceous earth and dried. The product mixed with diatomaceous earth is placed in the upper layer of a silica gel column with 95 grams of 200-300 mesh silic...

Embodiment 2

[0045] This embodiment is used to illustrate the method for extracting tripterine provided by the present invention.

[0046] Take 1000 grams of dried root bark of the plant of the genus S. chinensis and crush it, extract it by percolating with ethanol at room temperature, and obtain 38 liters of tripterine with a content of 0.0169% by weight of the ethanol extract. The ethanol in the ethanol extract is removed to obtain an extract. The extract was suspended in 500 mL of water and then extracted with 300 mL of chloroform each time for a total of 5 extractions. Concentrate the chloroform extract to 18mL (the content of tripterine in it is 6.02g), mix the sample with 38g of diatomaceous earth, and dry it. The product mixed with diatomaceous earth is placed in the upper layer of a silica gel column with 170 grams of 200-300 mesh silica gel inside for adsorption chromatography separation. After the low polarity components are eluted with petroleum ether, petroleum ether and ethyl...

Embodiment 3

[0048] This embodiment is used to illustrate the method for extracting tripterine provided by the present invention.

[0049]Get the dry root bark of 150 grams of Tripterygium genus Tripterygium genus Tripterygium and pulverize, use 800mL methanol ultrasonic extraction each time, filter, extract altogether three times, wherein, the extraction time for the first time is 30 minutes, and the extraction time of last 3 times is After 20 minutes, the extracted products obtained each time were mixed to obtain 2210 mL of tripterine content of 0.0373 wt % alcohol extract. The methanol in the ethanol extract is removed to obtain an extract. The extract was suspended in 200 mL of water and then extracted with 200 mL of dichloroethane each time for a total of 7 extractions. Concentrate the dichloroethane extract to a small volume (about 3 mL, the content of tripterine in it is 0.82 g), mix the sample with 8 g of diatomaceous earth, and dry it. The product mixed with diatomaceous earth w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com