Polymer injection device free from dropping and fishing

A technology of distributing aggregates and free throwing and fishing, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of the influence of injection parameters, cumbersome locks, and complicated processes, so as to reduce the cost of oil production and improve the accuracy. The effect of high accuracy and reliability, and high measurement and adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

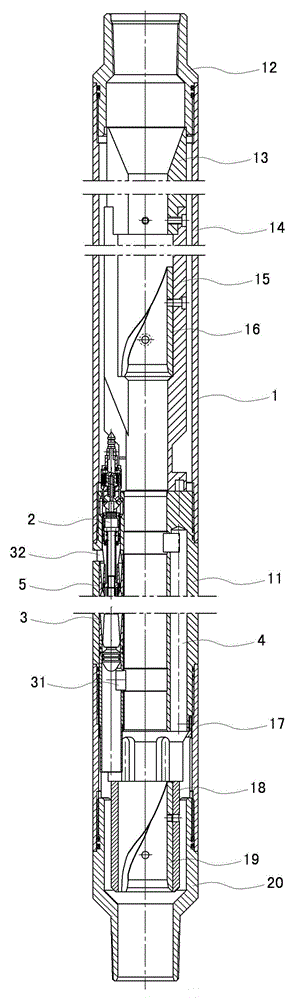

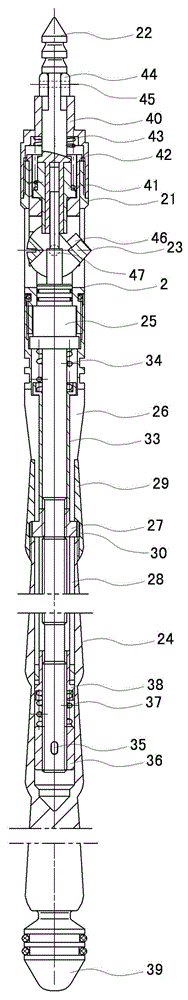

[0008] No-drop aggregators such as figure 1 , figure 2 As shown, it includes a polymerizer body 1 and a throttling core 2. The throttling core 2 includes an upper body 21, a fishing rod 22, a cam mechanism 23 and a shuttle rod 24. The lower part of the fishing rod 22 is provided with an upper end and a fishing rod. The lower end of the rod 22 is axially slidably matched and can rotate with the core rod 25 with the fishing rod 22. The lower part of the upper body 21 is provided with a sleeve on the core rod 25 and inserted into the shuttle rod 24. The upper end and the upper body 21 are threaded. The connected connecting sleeve 26, the nut 27 that is sleeved on the core rod 25 by threads is installed in the shuttle-shaped rod 24, the connecting sleeve 26 is located on the cylinder wall in the shuttle-shaped rod 24 and is provided with an axial bar hole 28, and the outer wall of the nut 27 A slider that can slide along the axial bar hole 28 is provided on the top; the axial th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com