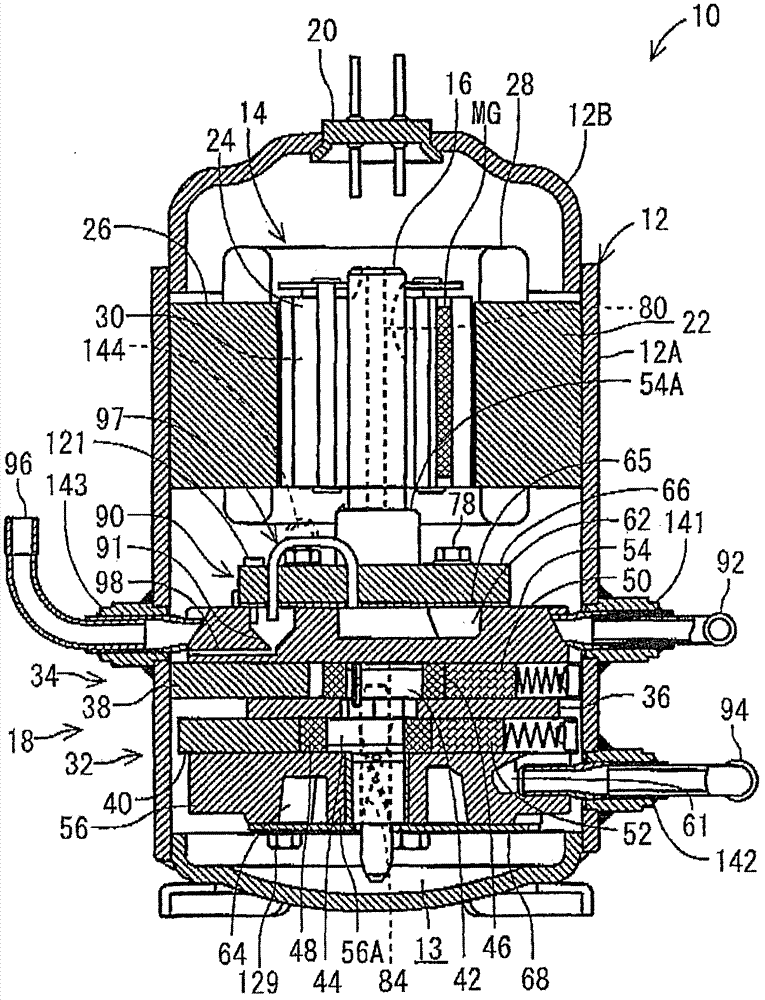

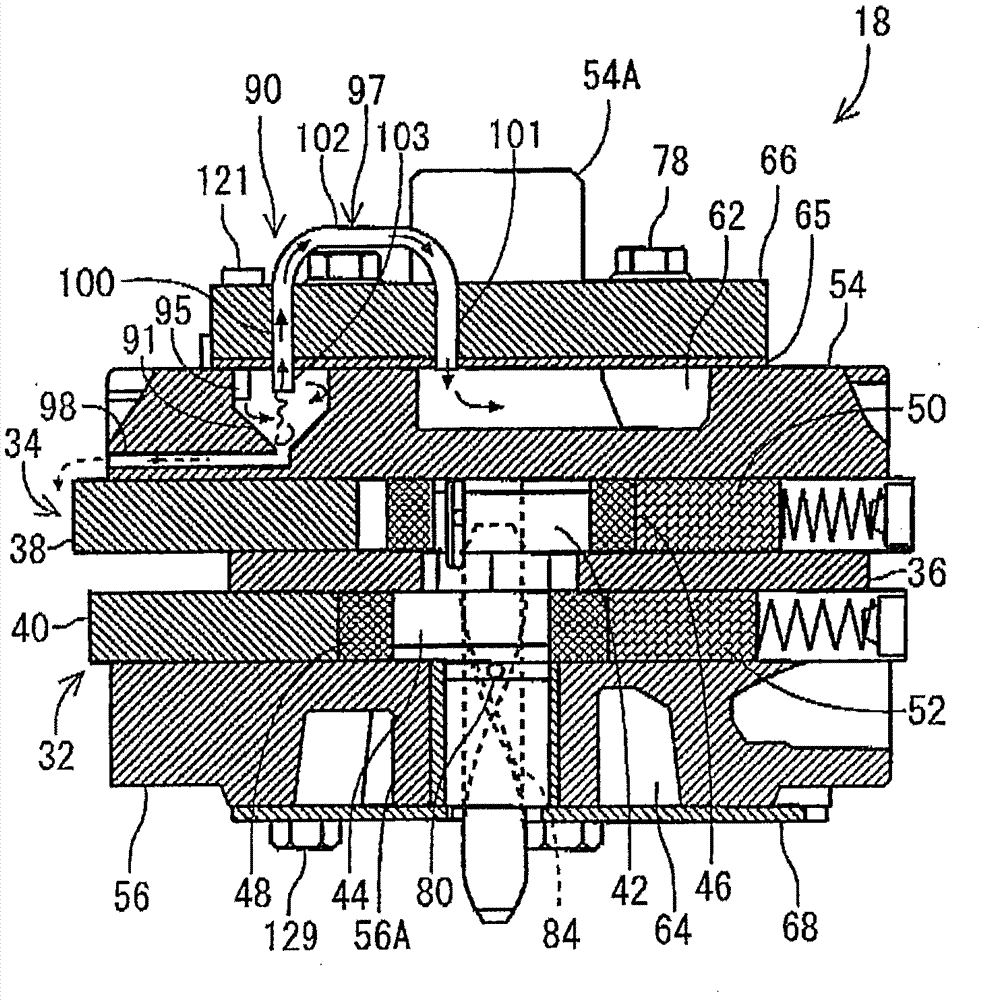

rotary compressor

A rotary compressor and rotary compression technology, applied in the field of rotary compressors, can solve the problems of complicated refrigerant paths, increased cost, increased thickness, etc., so as to suppress the increase in production cost and component cost, suppress the increase in the number of components, The effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

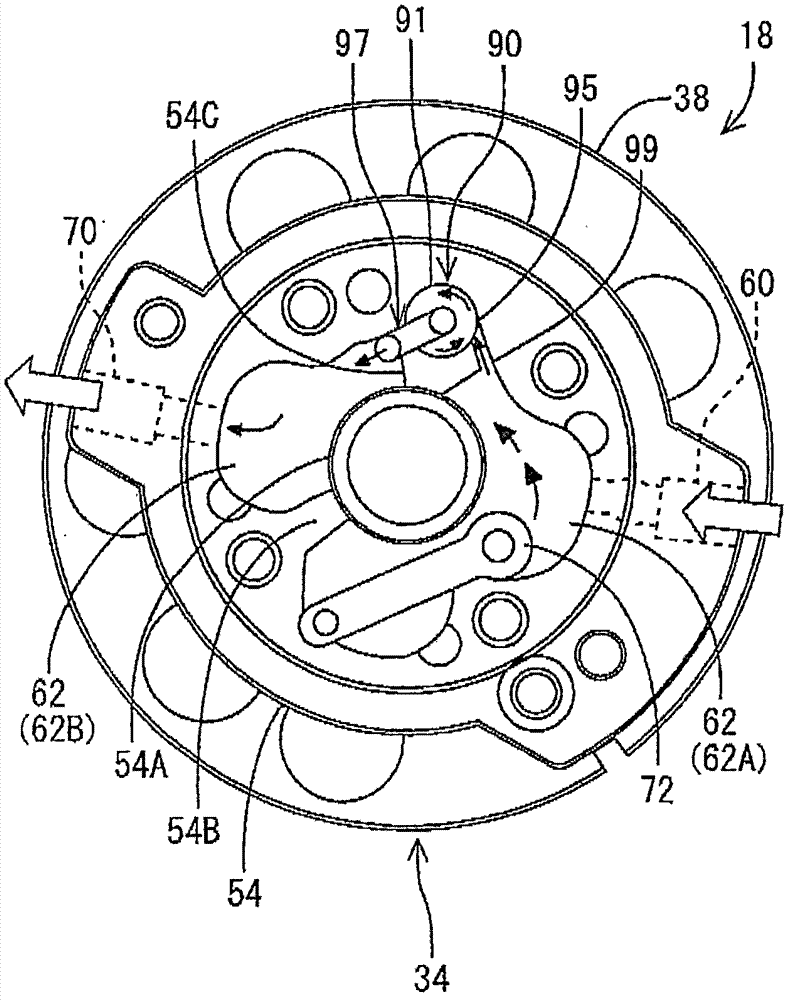

Embodiment 2

[0090] the following, Figure 5 with Image 6 A plan view (except for the upper cover 66 and the gasket 65) of the rotary compression mechanism portion 18 of the rotary compressor 10 of another embodiment of the present invention and its enlarged view are shown. At this time, the oil separation mechanism 90 is provided at two locations (90A, 90B) on the partition wall 54C of the upper support member 54, an introduction passage 99 communicating with the refrigerant introduction portion 95 of the first oil separation mechanism 90A, and a discharge valve 72 The discharge muffler chamber 62 (62A) on the side communicates with the refrigerant outlet 97 of the oil separation mechanism 90A and the introduction passage 99 of the second oil separation mechanism 90B. The refrigerant outlet 97 of the second oil separation mechanism 90B communicates with the discharge passage The discharge muffler chamber 62 (62B) on the 70 side communicates.

[0091] That is, in this embodiment, two oil sep...

Embodiment 3

[0094] the following, Figure 7 with Picture 8 A plan view (except for the upper cover 66 and the gasket 65) and an enlarged view of the rotary compression mechanism portion 18 of the rotary compressor 10 according to another embodiment of the present invention. At this time, the oil separation mechanism 90 is provided on the partition wall 54B and the partition wall 54C of the upper support member 54 respectively, and there are two (90A, 90B) in total, which are the same as the first and second oil separation mechanisms 90A, 90B. The introduction passage 99 communicating with the agent introduction portion 95 communicates with the discharge muffler chamber 62 (62A) on the discharge valve 72 side, and the refrigerant outlet portions 97 of the first and second oil separation mechanisms 90A and 90B are respectively connected to the discharge passage 70 side. The muffler chamber 62 (62B) communicates.

[0095] That is, in this embodiment, two oil separation mechanisms 90 (90A, 90B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com