Anti-loosening fastening device

A strong and anti-loosening technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve problems such as difficult to withstand repeated shocks, difficult processing and operation, and inapplicable disassembly or installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention are described below through specific examples, and the following examples are only for illustrating the present invention rather than limiting the scope of the present invention.

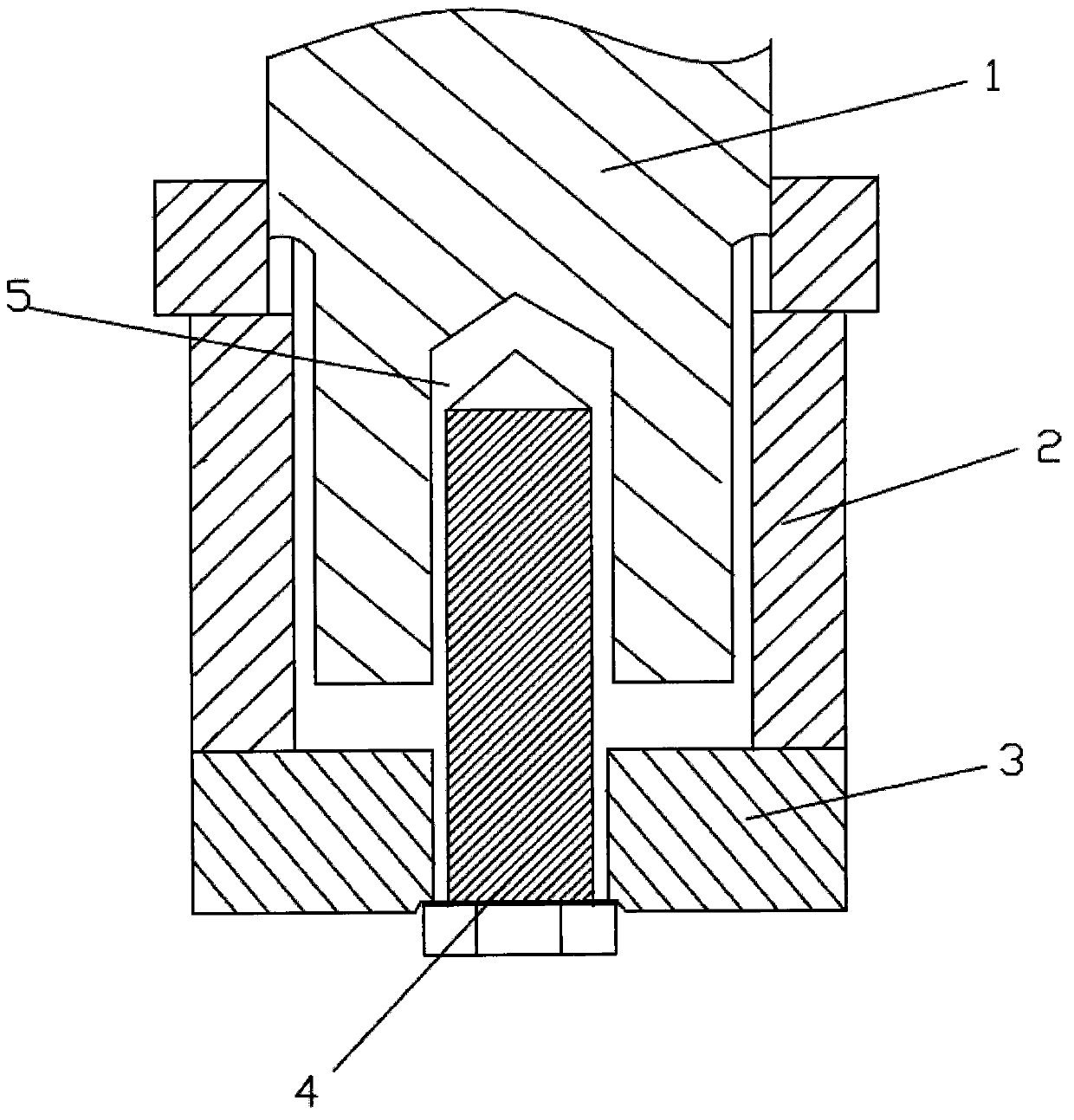

[0013] A kind of anti-loosening firm device, including bolt 1 and nut 2; An internally threaded hole 5 is provided at the end of the bolt 1, and the direction of the internal thread in the internally threaded hole 5 is opposite to the direction of the external thread of the bolt 1; When engaging with the nut 2, the end of the bolt 1 does not exceed the outer end surface of the nut 2; the fastening device also includes a gland 3 with a locking screw 2 fixed in the center, and the locking screw 4 is the same as the end of the bolt. Compatible with internally threaded holes.

[0014] The gland is provided with a circular protrusion with the center of the gland as the center of a circle, and the purpose of the protrusion is to reduce the protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com