Method for designing O-shaped rubber sealing ring

A technology of rubber sealing ring and design method, which is applied in the field of rubber sealing ring, can solve problems such as ambiguity and database confusion, and achieve the effect of clear database and reducing the number of models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

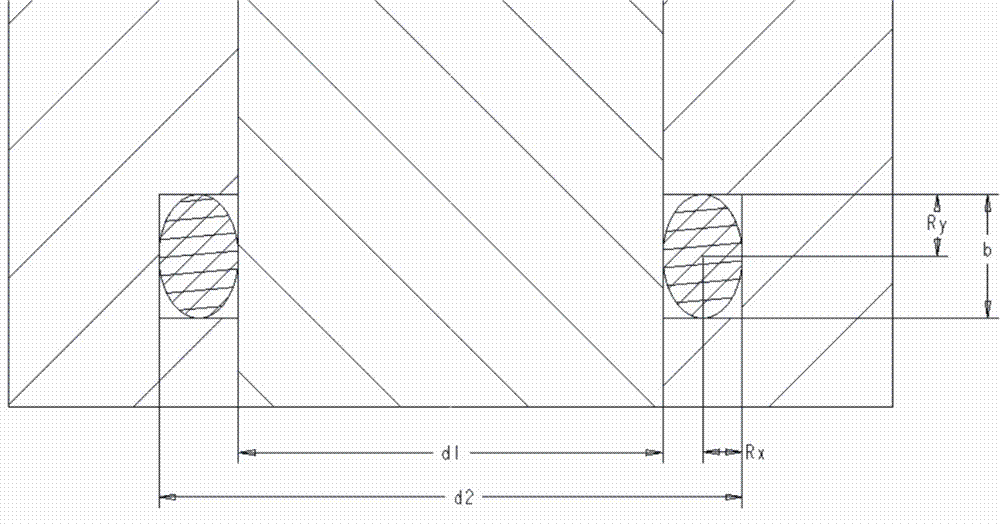

[0010] A kind of design method of O type rubber seal ring, this design method comprises the following steps:

[0011] (1) When using the three-dimensional design software Pro / e to design the O-shaped rubber sealing ring, design the cross-sectional shape of the O-shaped rubber sealing ring as an ellipse, and set the direction of the center line of the O-shaped rubber sealing ring to the major axis or short axis of the ellipse. The axial direction is parallel, and at the same time, the length Ry of the major axis is equal to the length Rx of the minor axis, that is, Ry=Rx, and an O-shaped rubber sealing ring in a free state is generated;

[0012] (2) When drawing the assembly drawing, use the three-dimensional model in the compressed state to flexibly process the length Ry of the major axis and the length Rx of the minor axis of the elliptical section, and adjust the length of the major axis and minor axis of the ellipse to meet the assembly requirements , adjust the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap