Method for decreasing walking beam heating furnace steel billet water beam black mark

A walking beam and heating furnace technology, applied in the field of heating furnace billet heating, can solve the problems of increased energy consumption, coarse grains, increased equipment investment, etc. black print effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

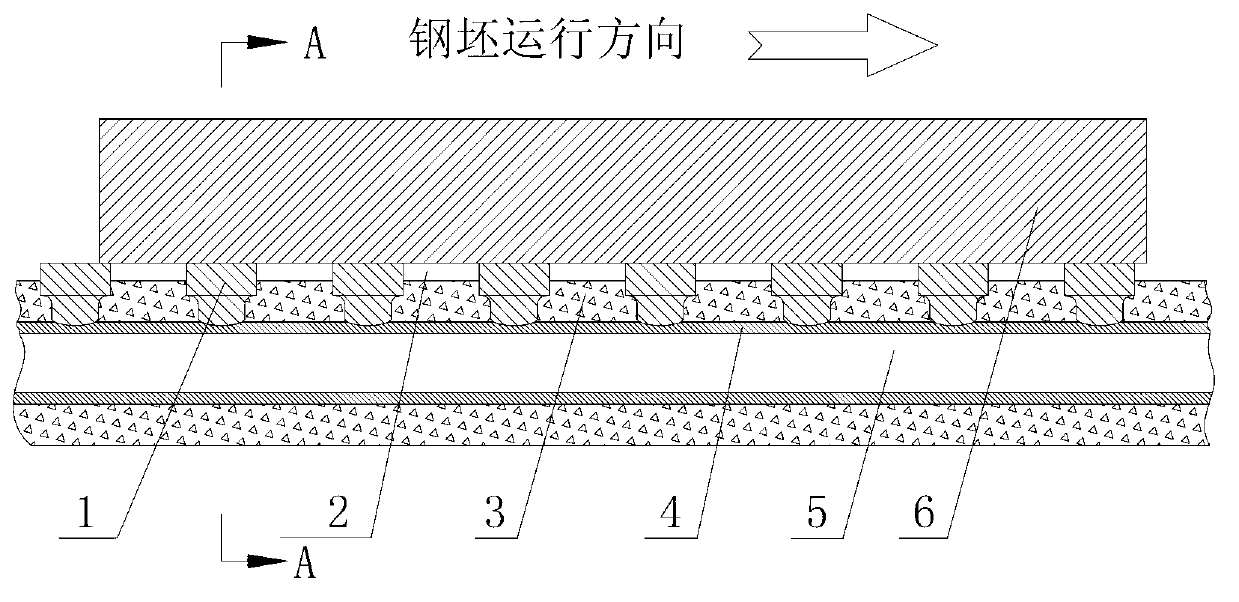

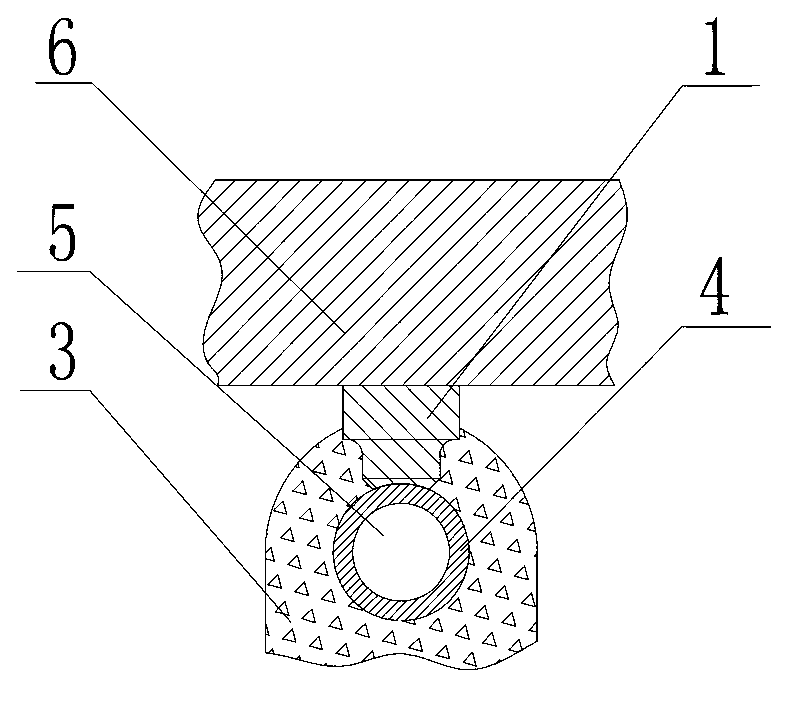

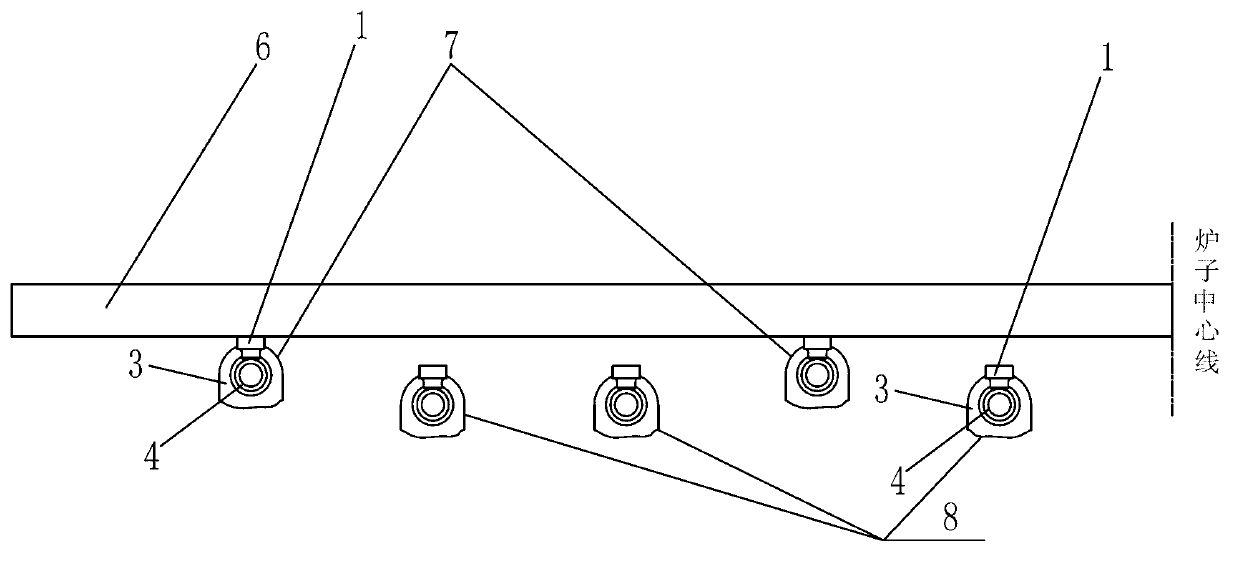

[0028] Figure 1~3 The working state of the shown steel billet on the water beam of the heating furnace in the walking beam heating furnace has been introduced in detail in the background technology, and will not be repeated here.

[0029] The method for reducing the black mark of the billet water beam of the walking beam heating furnace designed by the present invention comprises the following steps:

[0030] Step 1: Control the steel pusher to push the steel billet 6 onto the heating furnace water beam of the walking beam heating furnace, the heating furnace water beam includes a fixed beam 7 and a walking beam 8, and the fixed beam 7 and the walking beam 8 A spacer 1 is arranged on it;

[0031] Step 2: Adjust the horizontal walking distance of the walking beam 8 in the water beam of the heating furnace to n(L d +L s )+L d , where n is a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com