Hydraulic walking-beam type round billet heating furnace cushion block and using method thereof

A round billet heating and walking beam technology, which is applied in the field of steel rolling heating furnace, can solve the problems of increasing the manufacturing cost of round steel heating area pads, high manufacturing costs, and easy black marks, so as to reduce the difficulty of fixing and save materials Dosage, the effect of reducing black marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

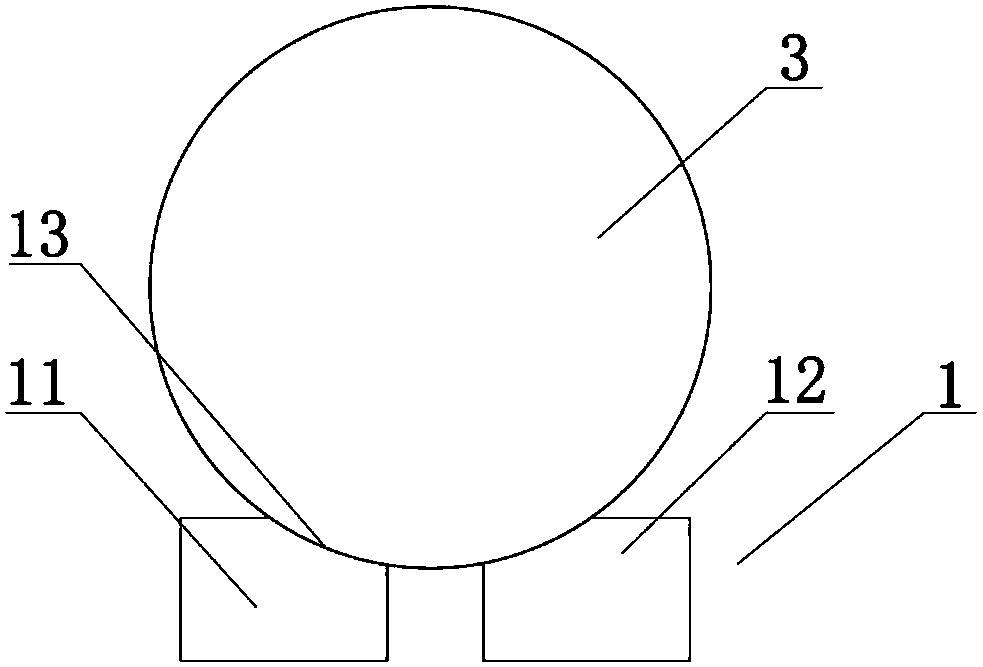

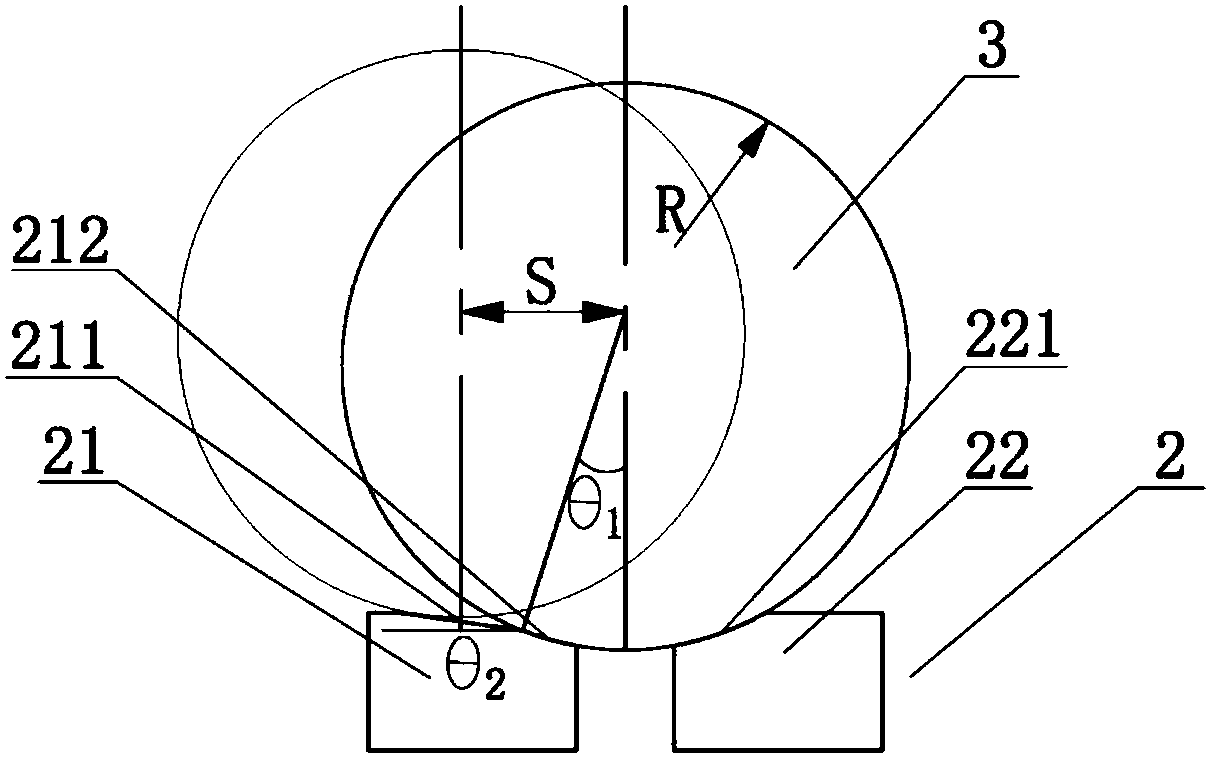

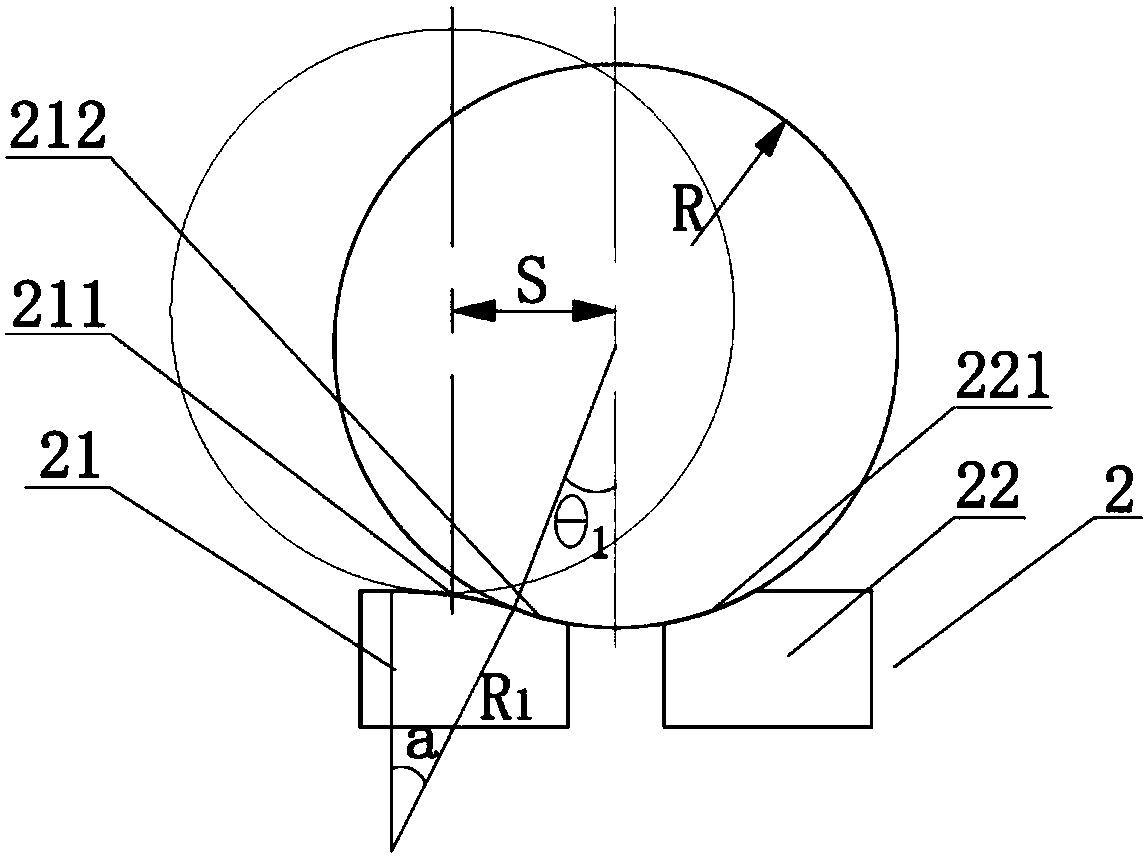

[0032] Concrete embodiment of the present invention is: as figure 1 , figure 2 , image 3 As shown, a hydraulic walking beam type round billet heating furnace block includes a first split type block 1 fixed on the walking beam 4 for supporting the round billet 3 and fixed on the fixed beam 5 to make the round billet 3 roll, The positioned second split pad 2 enables the round billet 3 to pass through the preheating section, heating section, The soaking section completes the entire heating process. In this process, the heating area of the round billet 3 is not only increased, but also the round billet 3 is lowered by the walking beam 4 so that the round billet 3 is placed on the second split pad of the fixed beam 5 2, the round billet 3 can roll on the second split pad 2, which reduces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com