Brush Terminal Assembly

A terminal device and brush technology, applied in electrical components, circuits, battery pack components and other directions, can solve the problems of operator injury, low efficiency, high labor intensity, etc., and achieve the effect of reducing injuries, reducing costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing:

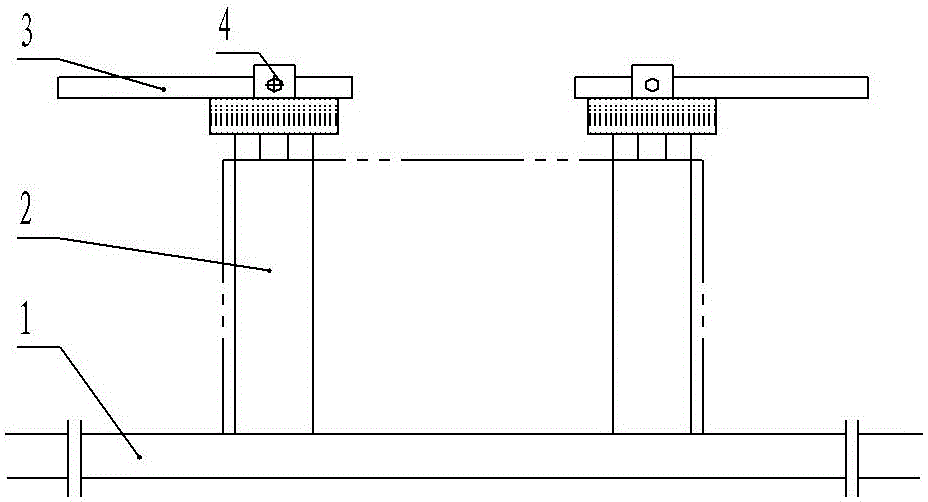

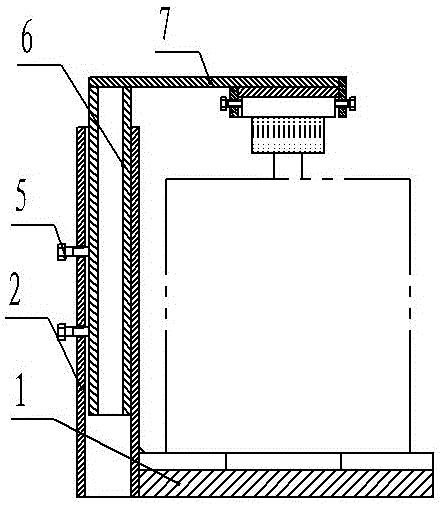

[0014] Such as figure 1 , figure 2 The brush terminal device shown includes a workbench 1, and a support cylinder 2 is welded on one side of the workbench 1. In this embodiment, there are two support cylinders welded; each support cylinder 2 is inserted with a Telescopic link 6, telescopic link 6 is connected with support cylinder 2 by bolt 5; Steel wire brush 3 is contained in the opening groove of upper support 7, and steel wire brush 3 is connected with upper support 7 by fastening screw 4, and the brush body portion of steel wire brush 3 is positioned at the below of upper support 7.

[0015] Before the assembly line starts, workers adjust the height of the wire brush 3 according to the model of the lead-acid battery produced, or need to replace a new steel brush; when the assembly line starts, the lead-acid battery moves on the conveyor belt of the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com