Compression assembly with dumbbell-shaped rotor for compressor

A dumbbell-shaped, compressor technology, applied in the field of compressors, can solve the problems of waste of resources and space, and achieve the effect of increasing the displacement, increasing the compression stroke, and increasing the number of teeth of the star gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

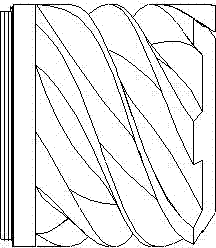

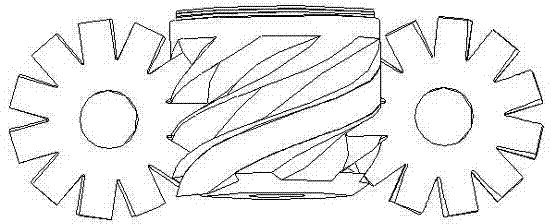

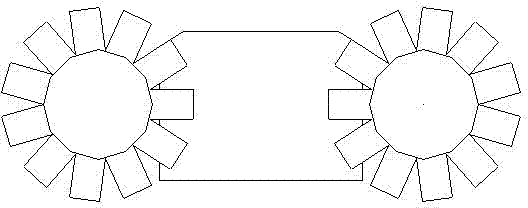

[0018] as attached Figure 4-6 Shown is a compression assembly with a dumbbell-shaped rotor for a compressor according to the present invention, which includes a rotor 1 and two symmetrically arranged star wheels 2, and the two star wheels 2 are respectively meshed on both sides of the rotor 1; Each of the star wheels is provided with 11 star gear teeth; the rotor 1 is provided with 10 compression slots (not marked), and each of the compression slots starts from the intake end of the rotor 1 to the exhaust end The spiral is performed, and the outer radius of the compression groove first decreases and then increases, forming a dumbbell shape. The outer radius of the compression groove at the intake end of the rotor 1 is smaller than the outer radius of the compression groove at the air outlet, and the groove depth of each compression groove is H1 The same; the tooth tip of each compression groove of rotor 1 is the same; when the star wheel 2 and the rotor 1 are in the working e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com