Laminating mechanism of storage battery electrode plate packing machine

A technology of wrapping machine and battery, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as reduced work efficiency, drop, large drop, etc., to improve production efficiency and continuous operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

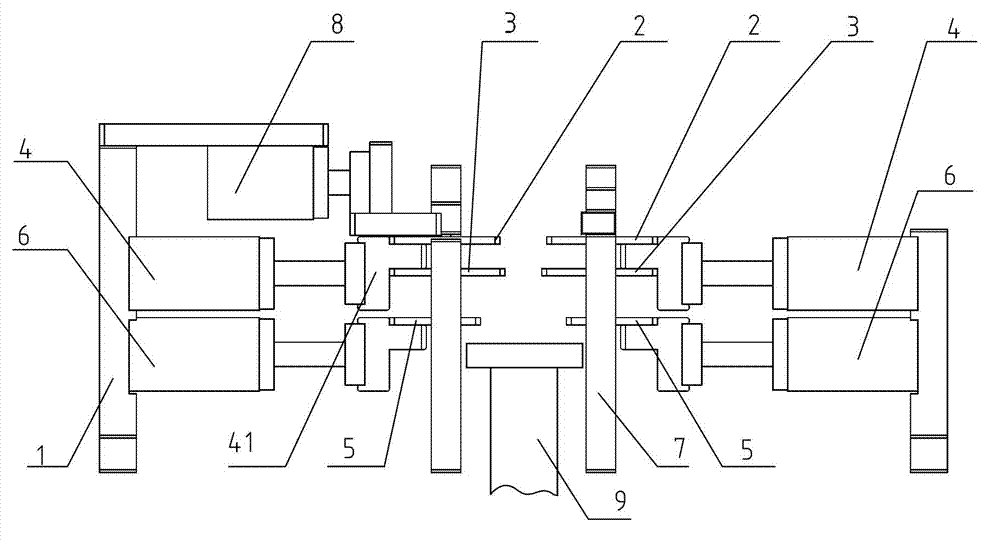

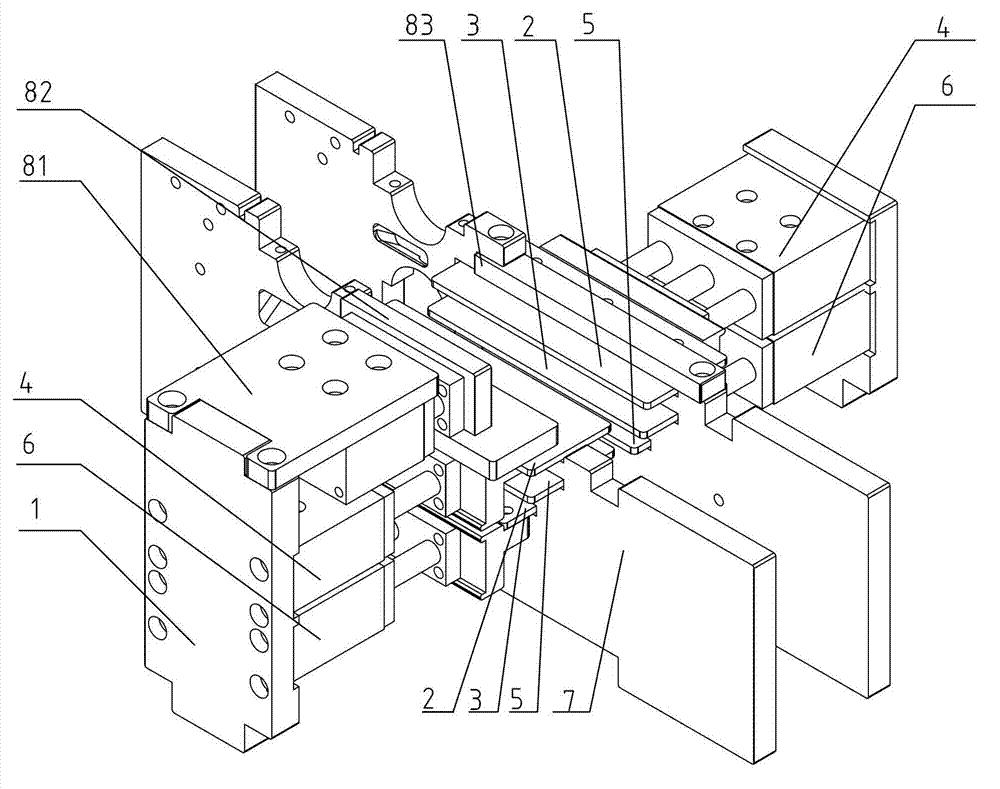

[0015] refer to figure 1 and figure 2 , which shows a stacking mechanism of a battery wrapping machine in the present invention, including a frame 1, and the frame 1 is provided with two opposite side baffles 7, and the side baffles 7 are provided with laterally movable The upper pallet 2 and the lower pallet 3, a blanking device is provided directly above the upper pallet 2, the lower pallet 3 is connected to the wrapping port of the wrapping machine, and the lower pallet 3 is provided with a lift Platform 9, between the lifting platform 9 and the lower pallet 3, there is a buffer pallet 5 that can move laterally. The blanking device transfers the first plate to the upper supporting plate, and the wrapping device of the wrapping machine transports the wrapped plate to the lower supporting plate, and the upper supporting plate and the lower supporting plate are withdrawn at the same time to wrap the wrapped plate and the first pole. The plates are superimposed on the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com