Starter motor assembly with soft start solenoid

A solenoid and starter technology, used in engine starting, electric components, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

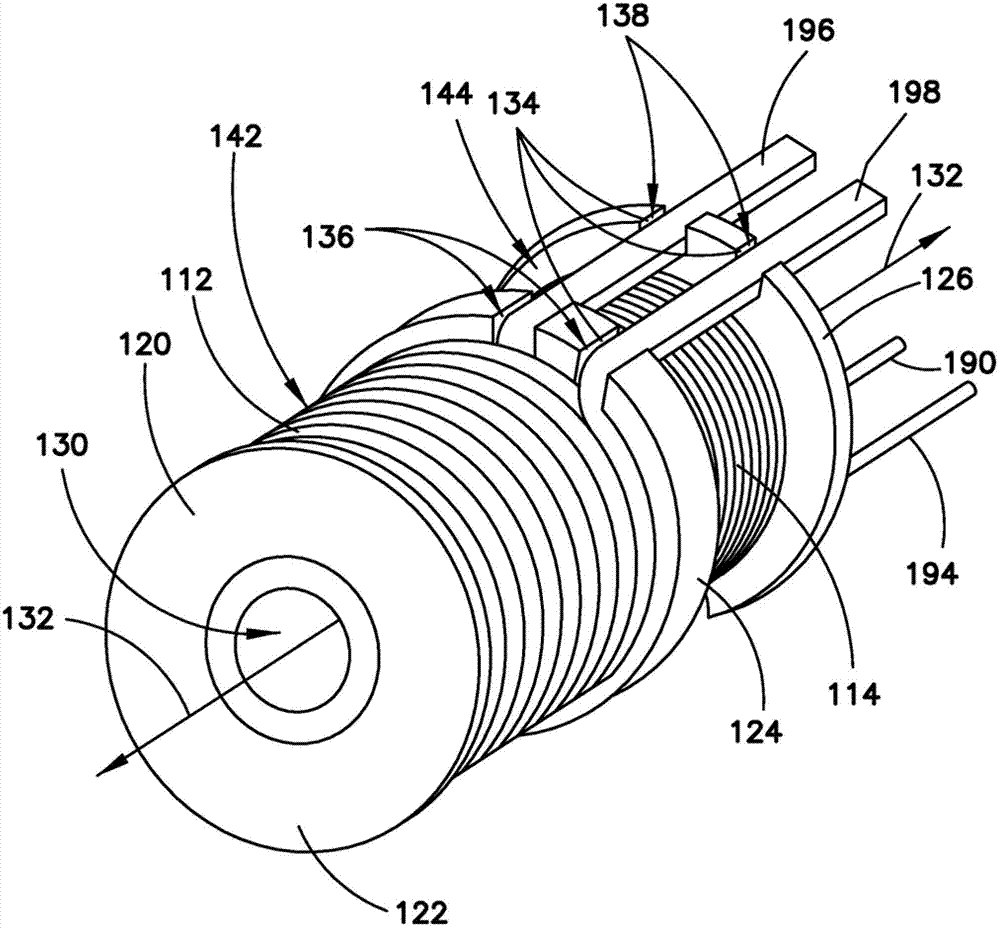

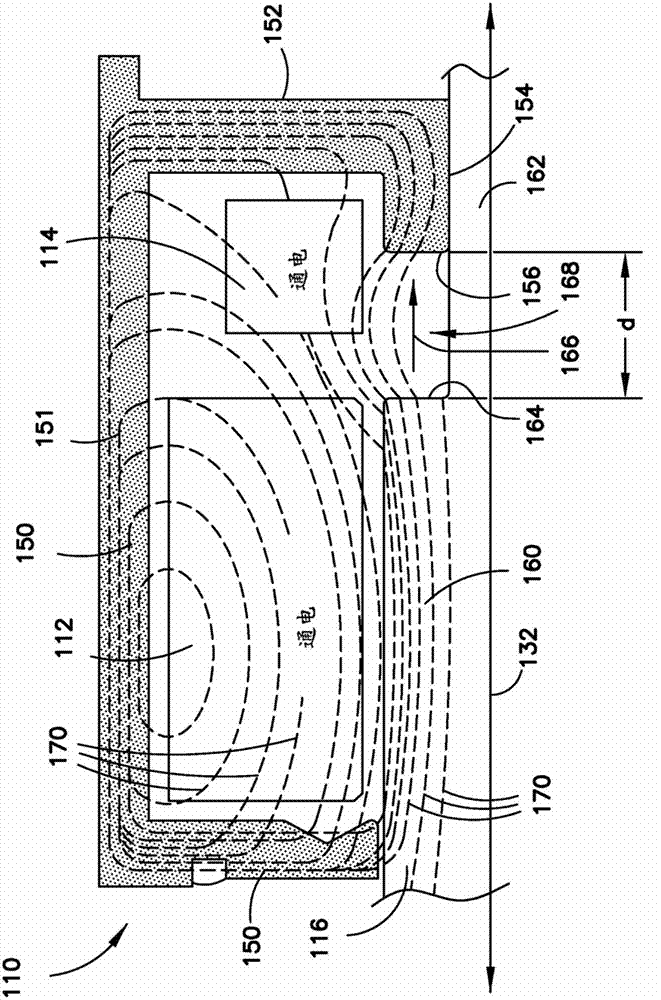

[0033] overall starter structure

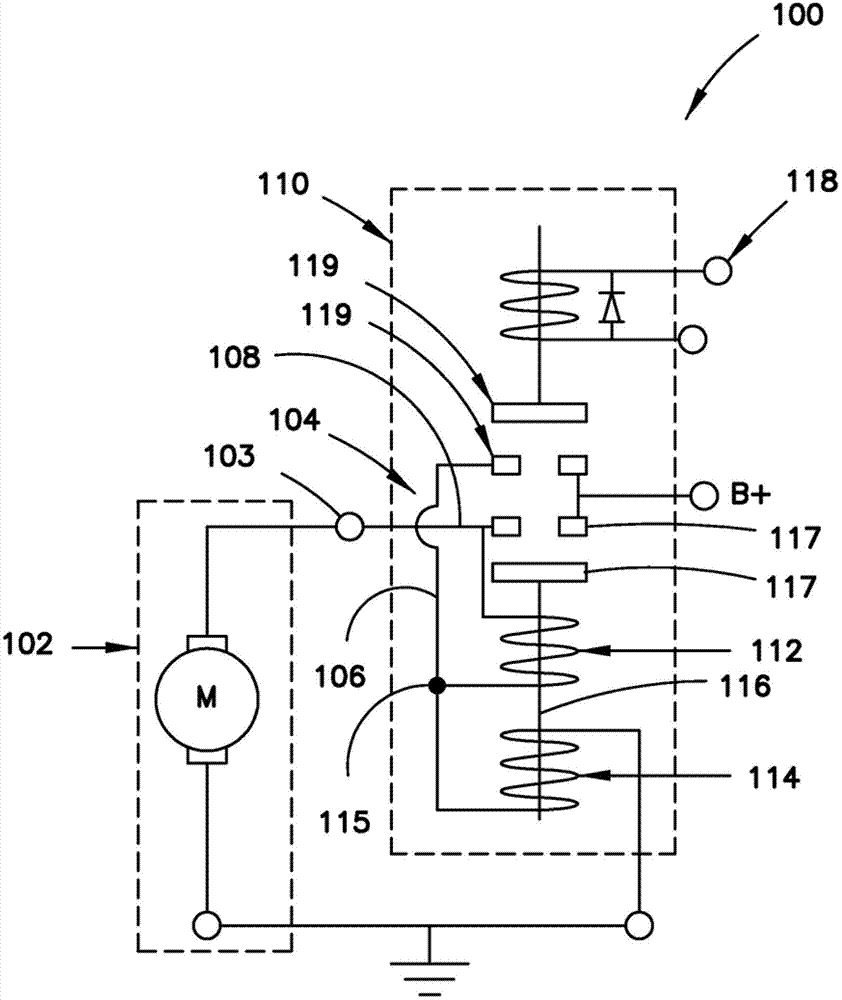

[0034] refer to figure 1 , in at least one embodiment, a starter 100 for a vehicle includes a motor 102 and a solenoid 110 . although figure 1 Not shown, but the starter 100 also includes a drive mechanism and pinion, similar to the conventional starter assembly 200 described above with reference to FIG. 15 . figure 1 The motor 102 in the embodiment of the present invention is disposed in a motor circuit 104 configured to connect the motor to a vehicle battery (not shown) via the B+ terminal. A solenoid 110 is provided in the motor circuit 104 to facilitate connecting the motor to the vehicle battery. The solenoid includes a pull-in coil 112 , a hold coil 114 , a plunger 116 and an ignition switch 118 .

[0035] figure 1 The motor circuit 104 includes a first current path 106 and a second current path 108 configured to provide electrical power to the motor 102 . The first current path 106 starts at the B+ terminal, passes through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com