Automatic detection control system and control method for superfine wire precise wire arrangement edge

An automatic detection and thin wire technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of failure to work normally, high cost of CCD system, dust and corrosion, etc., and achieves practicability And the effect of high reliability, simple system structure and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

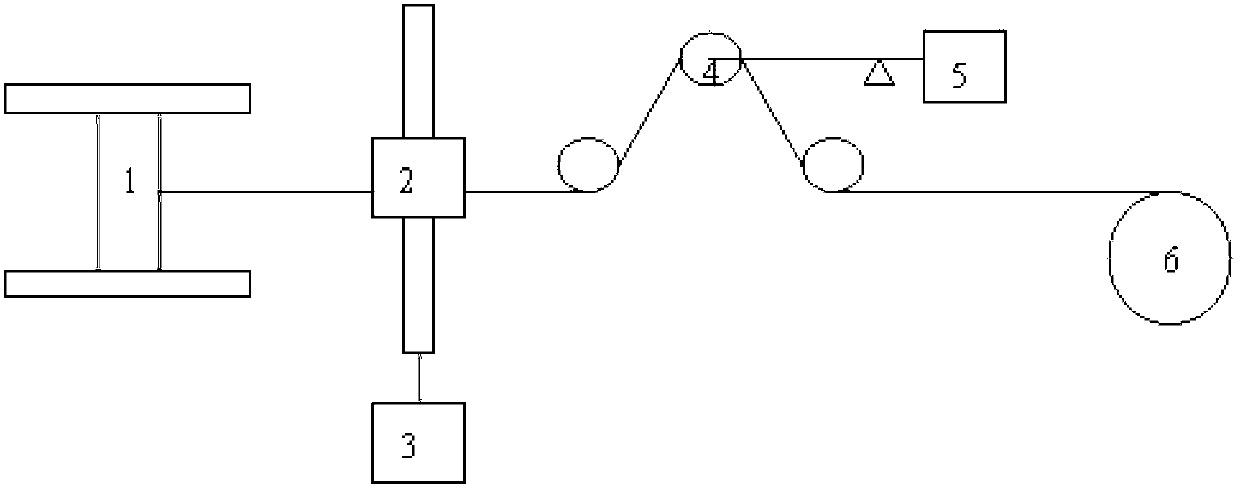

[0013] Such as figure 1 shown The invention is a system and a control method thereof that can be widely used in the automatic detection and control of the wire arrangement when the ultra-fine wire needs to be wound precisely. In the present invention, in front of the winding reel 1, a swing lever mechanism 4 is arranged between the wire arrangement mechanism 2 and the pay-off mechanism 6. The swing lever mechanism 4 includes an elastic swing lever and a wire guide wheel arranged on the elastic swing lever. The elastic swing bar is connected with a swing bar sensor 5, and an encoder or other cable sensor 3 is added to the cable screw rod at the same time. The encoder or other wire sensor 3 can judge the position of the wire in real time, and the flatness of the wire on the reel can be detected in real time according to the signal of the swing sensor on the elastic swing rod when the wire reaches the edge. The uneven phenomenon will be transmitted to the controller in real ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com