Rail transit double-contact-rail power supply system

A technology for rail transit and power supply systems, applied in power rails and other directions, can solve problems such as long-term corrosion effects of stray currents that cannot be fundamentally eliminated, affecting the safety and service life of structures and metal facilities, and threatening personal safety. Cost effective equipment investment and long-term maintenance costs, eliminate long-term corrosion effects, and avoid short-circuit failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

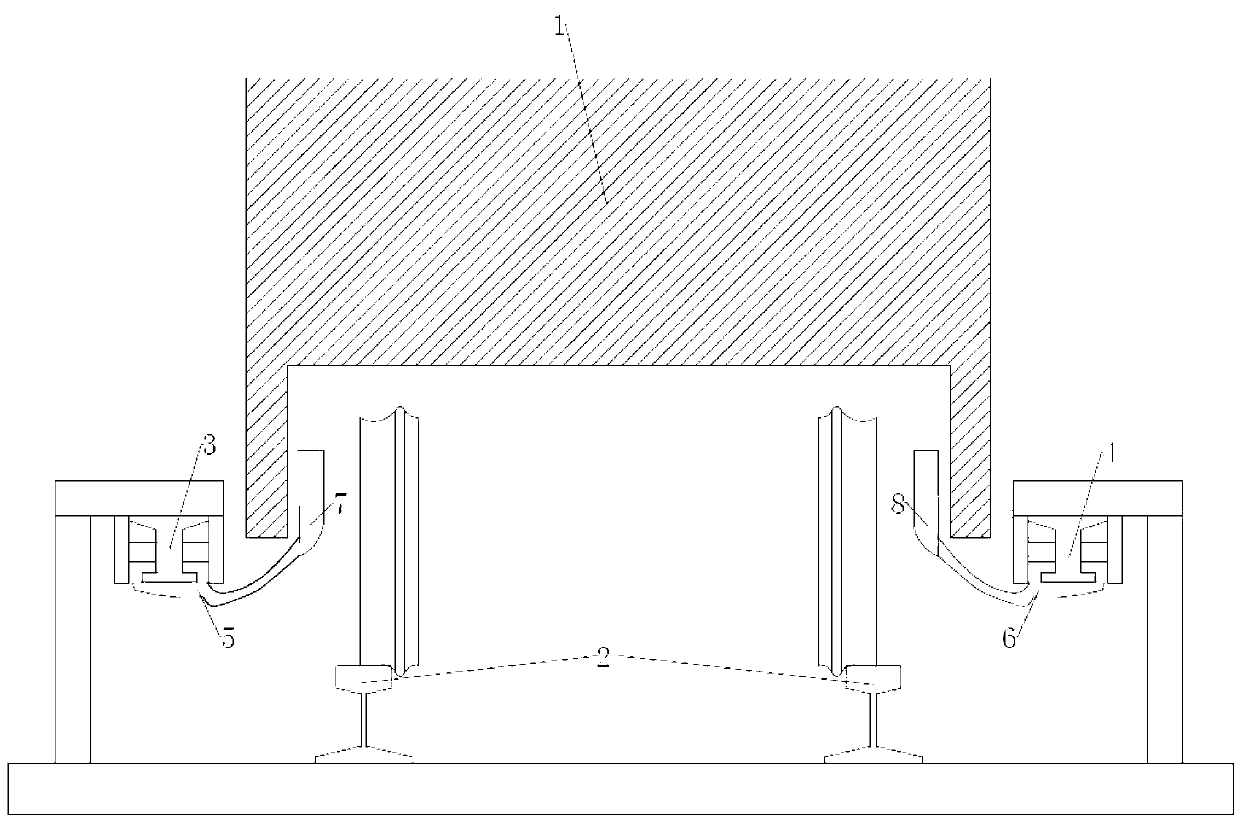

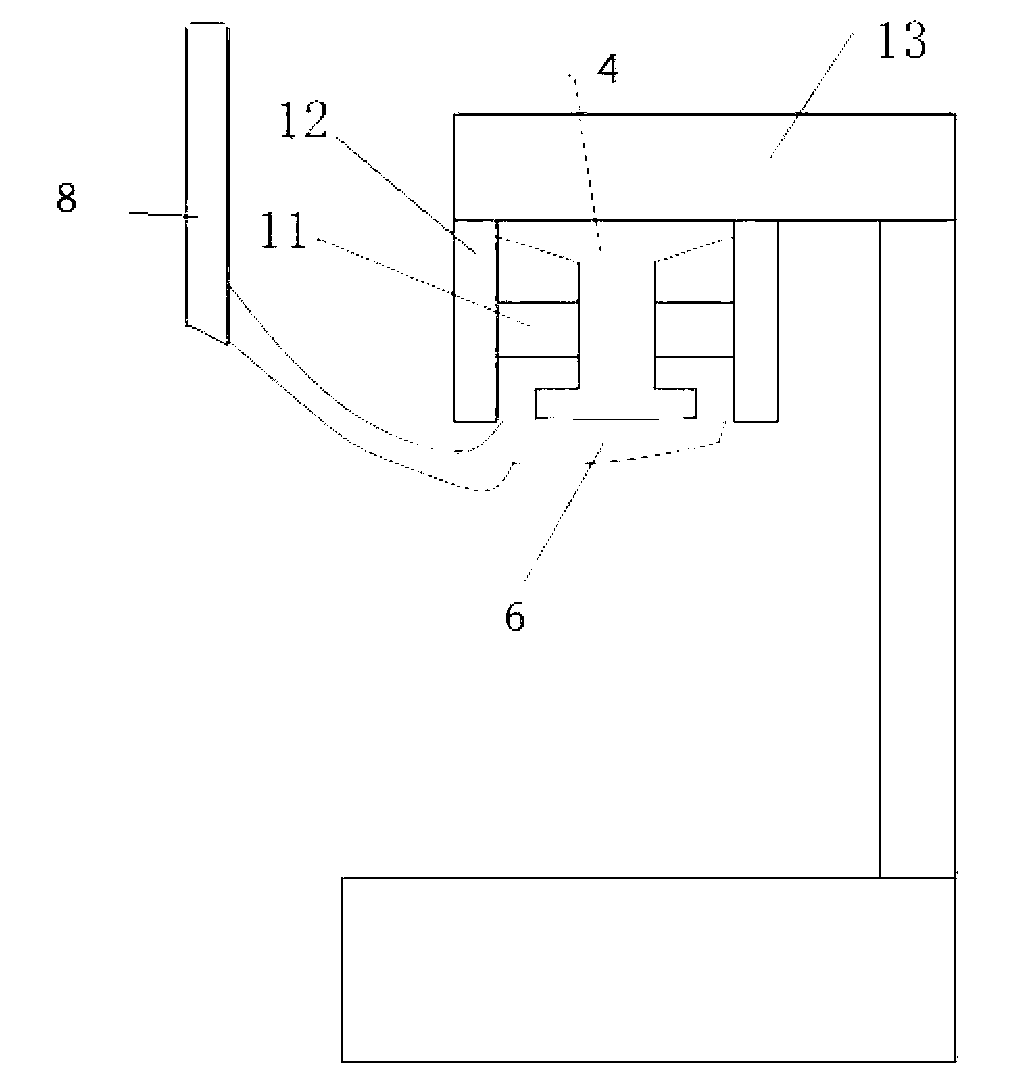

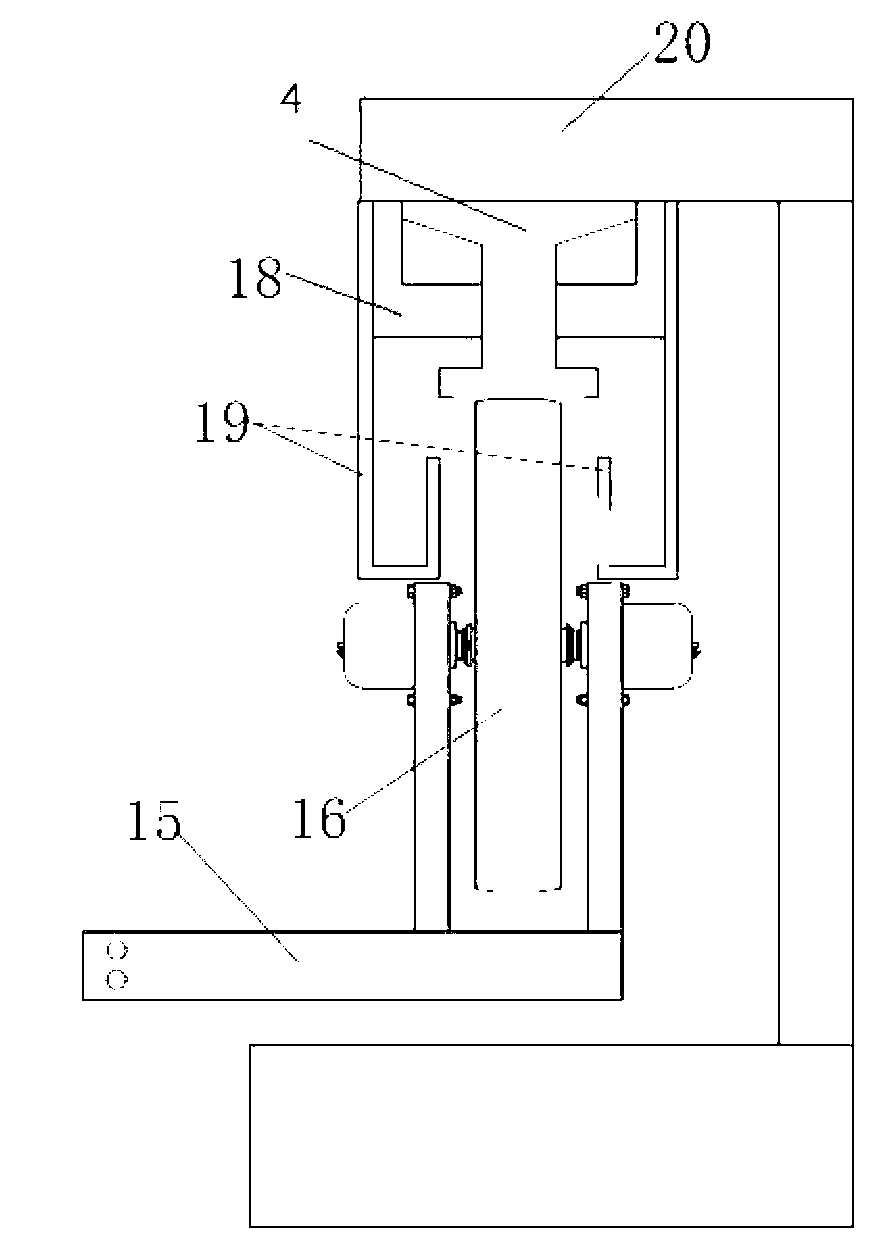

[0019] figure 1 Shown is the front view of the rail transit double contact rail power supply system. The left contact rail (power supply rail) 3 and the right contact rail (return rail) 4 are respectively arranged on the left and right sides of the running rail 2 of the rolling stock 1; the locomotive The left power receiving shoe 5 and the right power receiving shoe 6 are respectively installed on both sides of the designated part of the vehicle, and the left power receiving shoe 5 and the right power receiving shoe 6 are connected to the left contact rail (power supply rail) Contact movement on the side contact rail (return rail) 4; the left contact rail (power supply rail) 3 and the right contact rail (return rail) 4 are insulated from each other and ground, and the left power receiving shoe 5 and the right power receiving shoe 6 are connected to the bogie of the rolling stock 1 through the left insulating support 7 and the right insulating support 8 respectively. The left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com