U-shaped pipe tote cart

A U-shaped tube and turnover cart technology, which is applied in the direction of trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of U-shaped tube crushing, uneven settling oil content, and mutual entanglement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

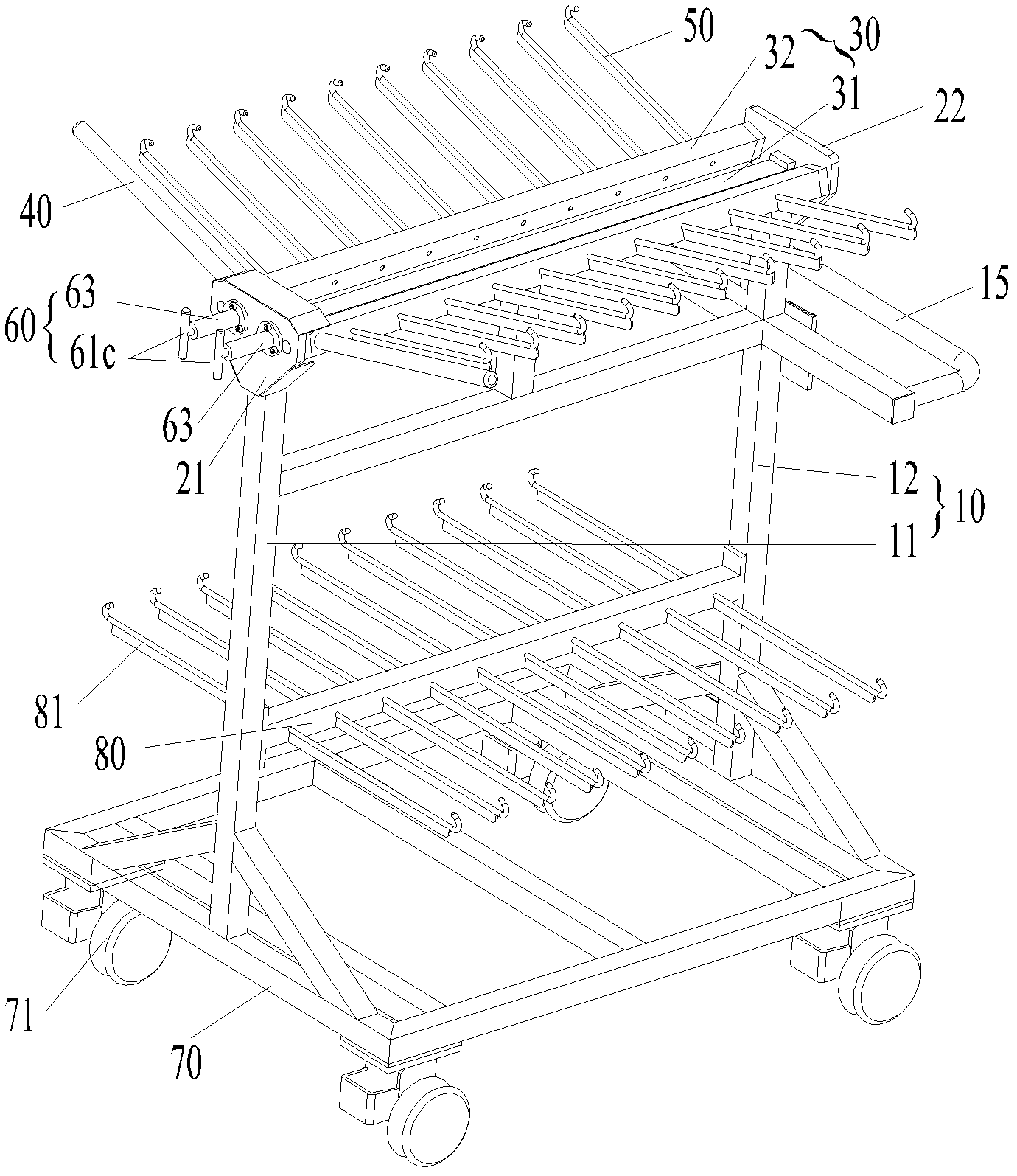

[0037] Such as figure 1 As shown, as shown, the present invention provides a U-shaped tube turnover vehicle, comprising: legs 10; crossbeams 30, arranged on the upper ends of the legs 10; stick out.

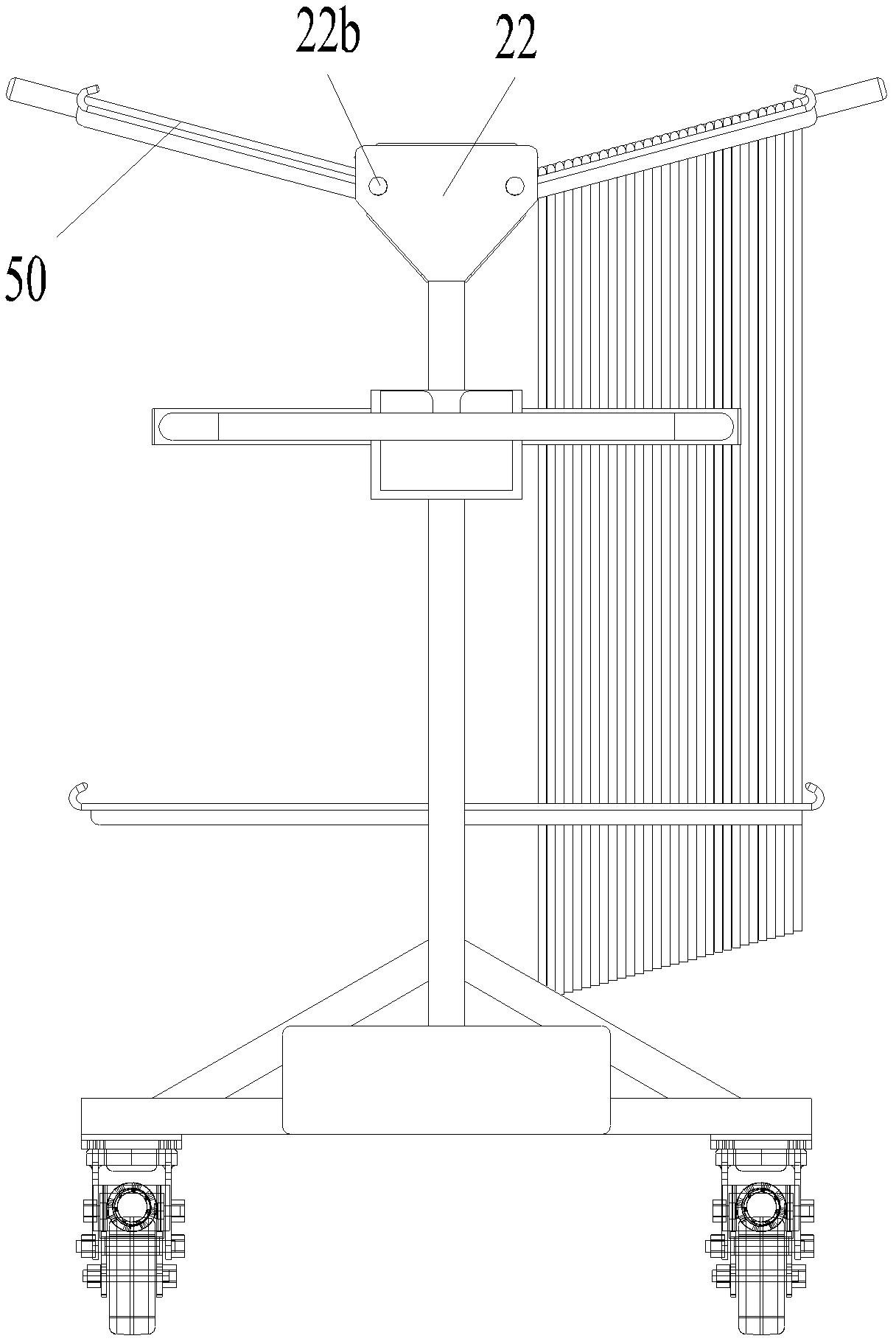

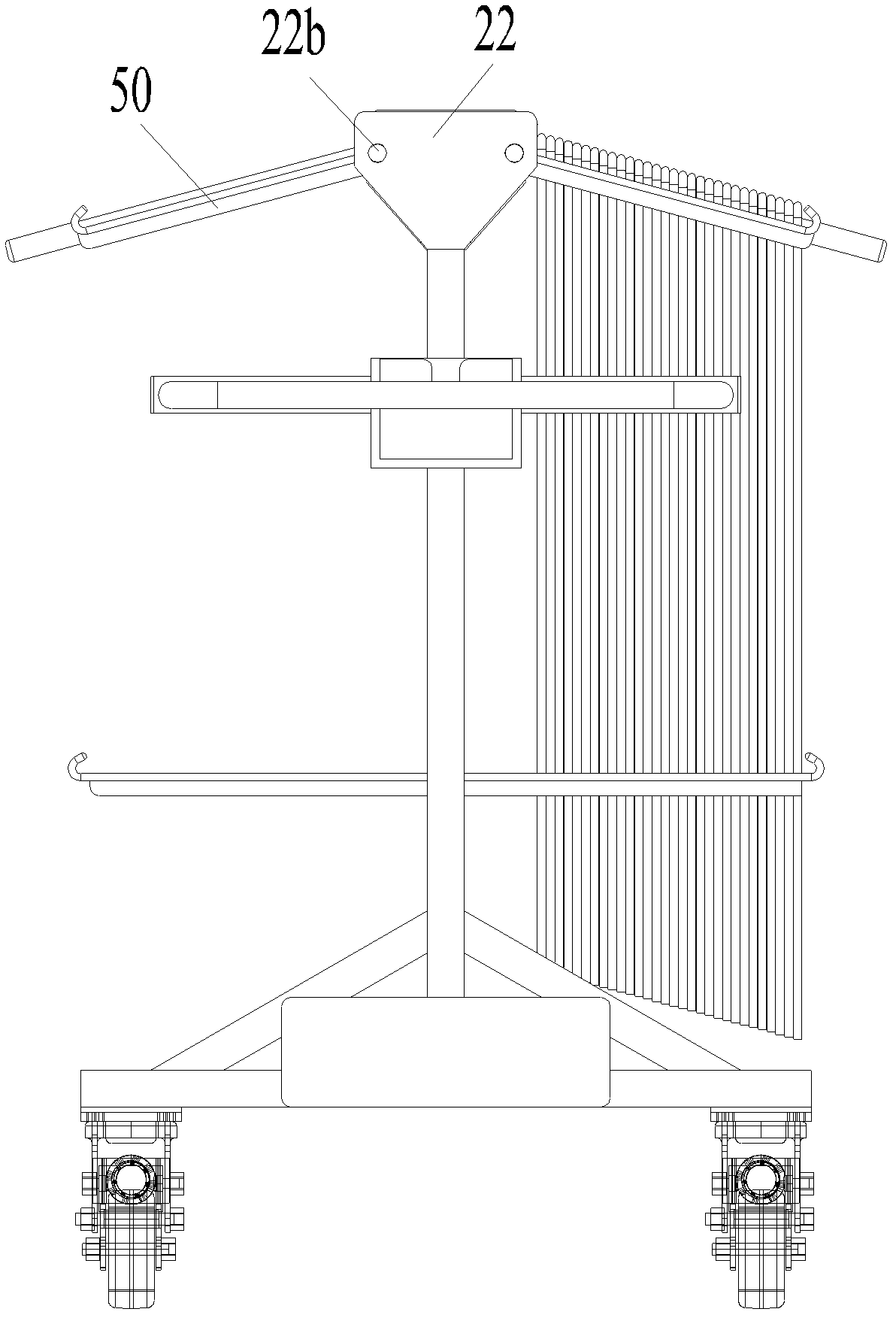

[0038] The U-shaped pipe hanging rod 50 is fixedly arranged on one side of the crossbeam 30, and the crossbeam 30 is rotatably arranged on the upper end of the support leg 10 in the radial direction, and is limited in an upturned position preventing the U-shaped pipe from falling off by the rotation positioning device 60 (such as figure 2 shown) and the down-tilted position for easy removal of the U-shaped tube (eg image 3 shown).

[0039] The design of the U-shaped hanging rod 50 which can adjust the angle is adopted, so that the U-shaped tube ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap